Three-dimensional jade ceramic tile and preparation method thereof

A three-dimensional, ceramic tile technology, which is applied in the field of ceramic tile preparation technology, can solve the problems of three-dimensional effect and poor texture of jade, and achieve rich decorative effects, high market price and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

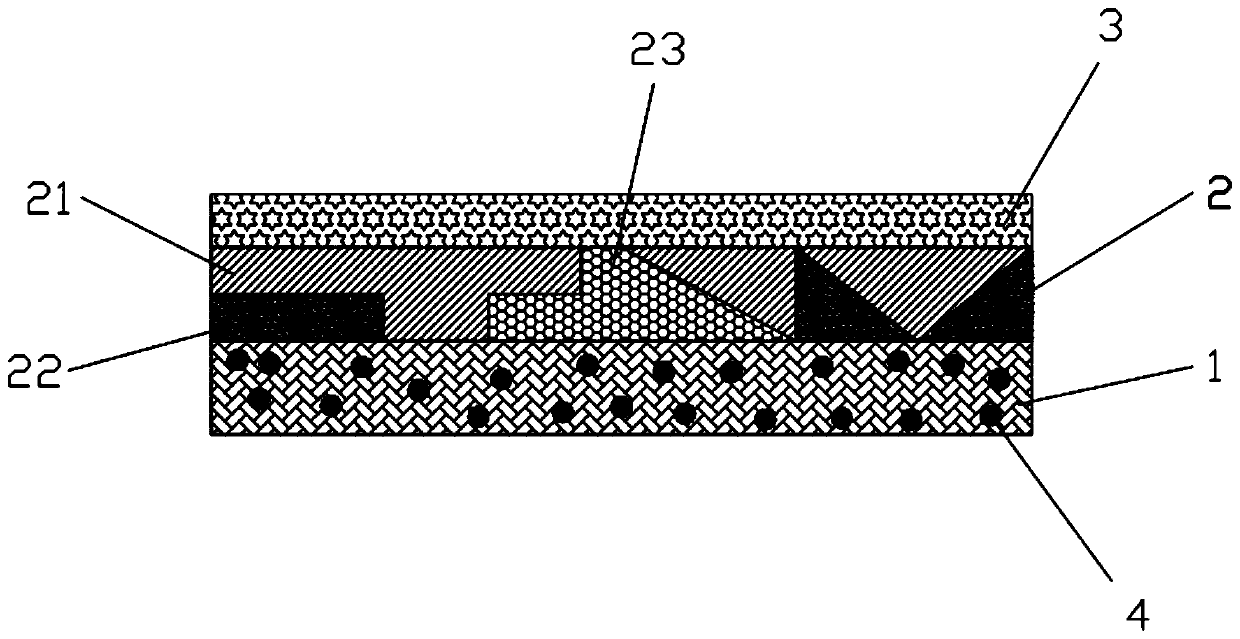

[0027] The preparation method of the three-dimensional three-dimensional jade ceramic tile of the present invention is as follows: first, batching is carried out according to the formula composition of the raw materials, after ball milling, sieving to remove iron, and spray granulation, the stale homogenization is carried out, and then the fabric is laid out in the form of digital fabric Layer and blank layer, because the ceramic tiles are pressed and formed in the way of anti-beating, so in the digital fabric, the fabric layer is first laid out and then the blank layer is laid out, and then pressed, dried, fired at high temperature, polished and waxed. Three-dimensional three-dimensional jade ceramic tiles.

[0028] The fabric layer is made of digital cloth. Firstly, the jade material is laid out in layers of different thicknesses according to the predetermined texture, and then the white material and high-temperature color material are laid out in different thickness layers a...

Embodiment 1

[0037] Weigh the jade material, white material and high-temperature color material according to the formula composition of the raw materials, and carry out stale homogenization after ball milling, sieving to remove iron, and spray granulation. / 100g glaze slurry, the moisture content of the dusting powder is 6.0%, the fineness of the powder is controlled: above 60 mesh ≤ 3%; 60-80 mesh: 45-55%; 80-100 mesh: 40-50%; below 100 mesh ≤5%; moisture is 5-6.5%. The fabric layer and the blank layer are laid out in the way of digital cloth, and three-dimensional jade ceramic tiles are obtained after pressing, drying, high-temperature firing, polishing and waxing.

[0038] The raw material composition of the jade material is calculated by weight: 40 parts of potassium feldspar, 5 parts of quartz, 18 parts of white clay, 15 parts of wollastonite, 2 parts of wollastonite, 20 parts of high temperature frit A; Composition: SiO2 69.18%; Al2O3 4.58%; K2O3.48%; Na2O 2.75%; CaO 9.40%; MgO 5.01...

Embodiment 2

[0042] Weigh the jade material, white material and high-temperature color material according to the formula composition of the raw materials, and carry out stale homogenization after ball milling, sieving to remove iron, and spray granulation. / 100g glaze slurry, the moisture content of the dusting powder is 6.0%, the fineness of the powder is controlled: above 60 mesh ≤ 3%; 60-80 mesh: 45-55%; 80-100 mesh: 40-50%; below 100 mesh ≤5%; moisture is 5-6.5%. The fabric layer and the blank layer are laid out in the way of digital cloth, and three-dimensional jade ceramic tiles are obtained after pressing, drying, high-temperature firing, polishing and waxing.

[0043] The raw material composition of the jade material is calculated by weight: 45 parts of potassium feldspar, 5 parts of quartz, 20 parts of white clay, 7 parts of wollastonite, 3 parts of wollastonite, 23 parts of high temperature frit A; Composed of: SiO 2 69.18%; Al 2 o 3 4.58%;K 2 O3.48%; Na 2 O 2.75%; CaO 9....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com