Preparation method of industrial grade lithium chloride

A lithium chloride, industrial-grade technology, applied in the field of preparation of industrial-grade lithium chloride, can solve the problems of strict control conditions, excessive barium ions and sodium ions, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

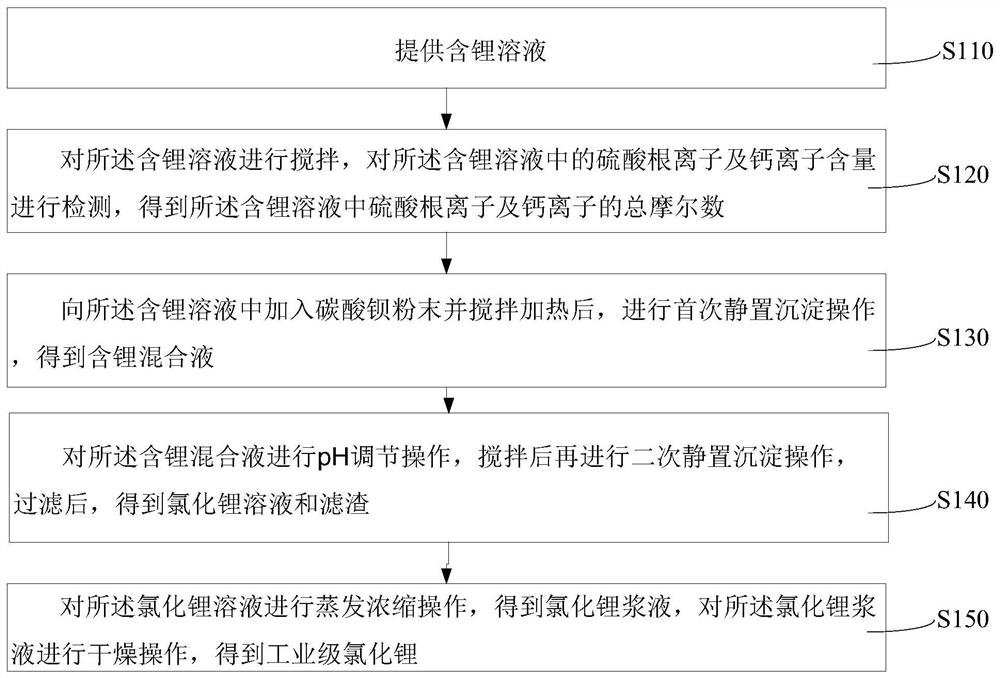

Method used

Image

Examples

preparation example Construction

[0029] S110, providing a lithium-containing solution.

[0038] SO

[0045] In one embodiment, in the first standing precipitation operation, the time for standing and precipitation is 2h~4h. Reasonable

[0048] In one embodiment, in the pH adjustment operation of the lithium-containing mixed solution, the adjusted pH is 9 to 12. Reasonable

[0051] In one embodiment, in the secondary standing precipitation operation, the standing precipitation time is 4h~8h. understandably,

[0057] In one embodiment, in the drying operation, the drying operation adopts a centrifugal drying operation. understandably, by

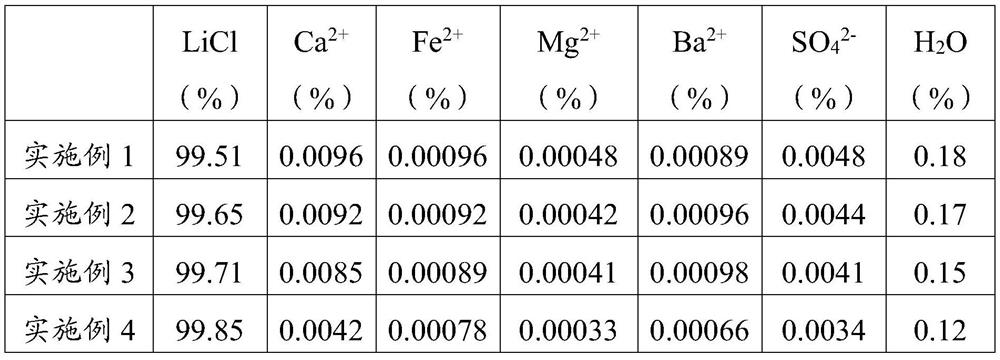

Embodiment 1

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com