Upper and lower disc spherical surface polishing mechanism for 3D optical element polishing machine

A technology of optical components and polishing mechanism, which is applied in the direction of optical components, surface polishing machine tools, optical surface grinders, etc., can solve the problems of low production efficiency, high cost, and inability to meet the mass production of multiple varieties of 3D components, and achieve production efficiency High, improve production efficiency, overcome the effect of unqualified polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

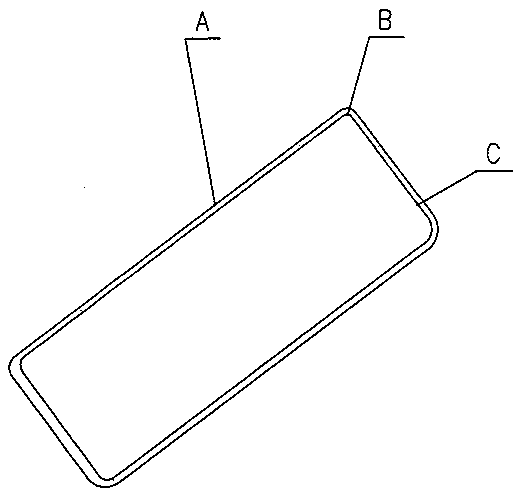

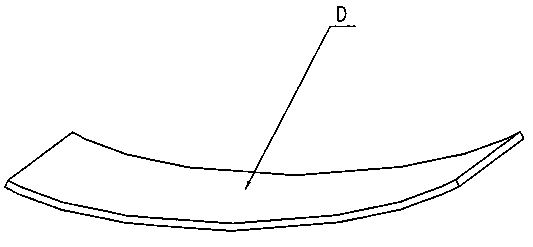

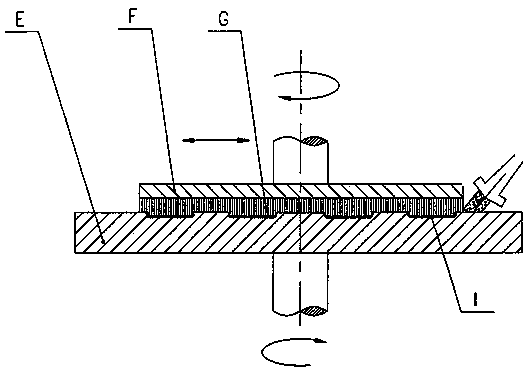

[0021] refer to Figure 4 , 1 , the main technical solution of the present invention is described: the present invention makes the workpiece lower plate 3 cooperate with the spherical brush 18 of the same curvature radius, and the folded surface A of the 3D element, the rounded part B between the folded surfaces and the The rounded portion C between the folding surface and the bottom surface is always subjected to the force of the brush, and is directly and effectively polished by the brush. The polishing mechanism of the present invention includes a first waterproof cover 1, a lower plate base 2, a workpiece lower plate 3, a brush plate base 4, a cover plate 5, a connecting bar 6, a ball valve 7, a second self-aligning bearing 8, a joint 9, a bearing pressure Cover 10, hexagonal nut 11, upper plate short shaft 12, screw 13, upper swing arm 14, second waterproof cover 15, water diversion ring 16, sealing ring 17, spherical brush 18, vacuum suction pipe 19, rotating main shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com