Method for improving rolled hard coiled strip steel surface reflectivity

A surface reflectivity and strip steel technology, applied in the field of cold-rolled pickling and rolling of hard-rolled strip steel, can solve the problem of low cleanliness, easy formation of zinc particles and zinc scars, and removal of residual oil and residue on the surface of cold-rolled strip steel. Solve problems such as lack of iron technology, achieve the effect of reducing surface residues, increasing reflectivity, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the steel grade group arrangement plan is 2200 tons.

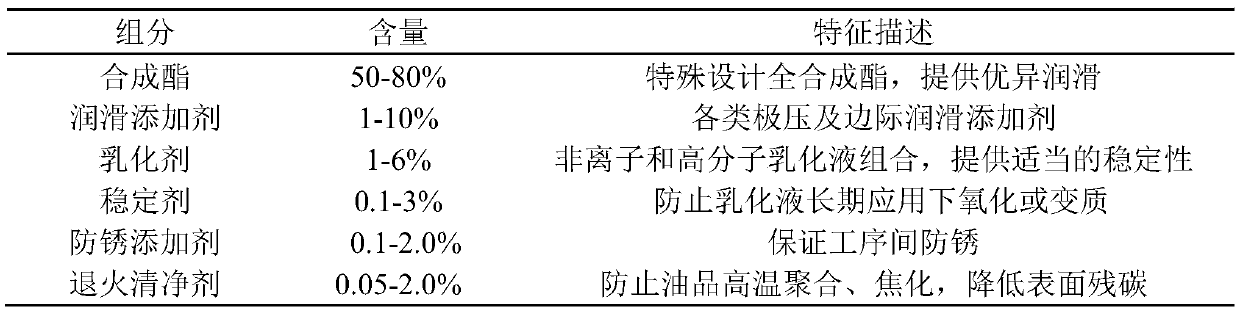

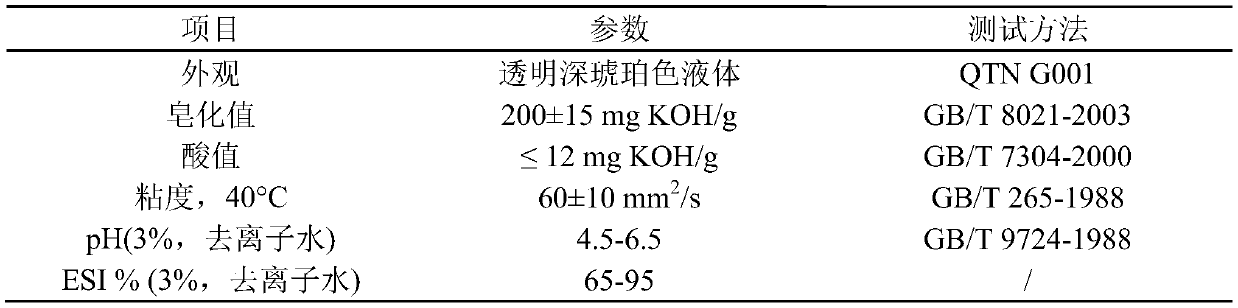

[0036] Rolling oil brand: Quakerol. Rolling oil type: MHS 1.0. The emulsion is obtained after the rolling oil is diluted. Rolling Oil Type: Non-ionic steady state rolling oil. The composition of rolling oil is shown in Table 1. The physical and chemical indicators of rolling oil are shown in Table 2.

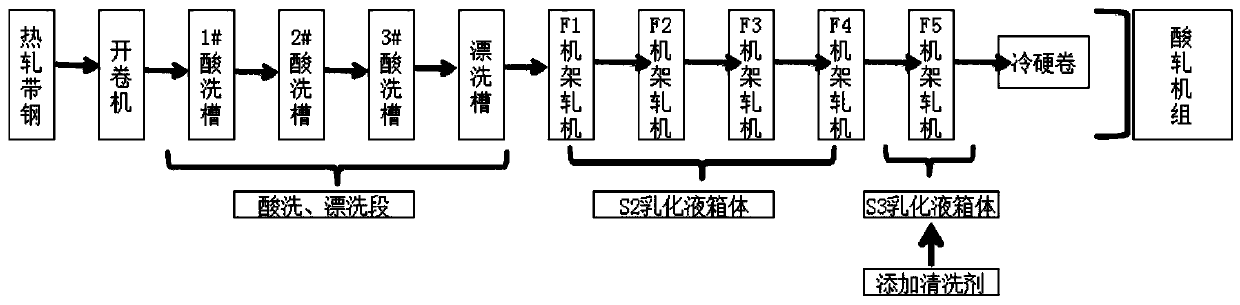

[0037] Cleaning agent brand: Quakerol. The cleaning agent model is: CLEAN-1.0, and the parameters are shown in Table 3. Part of the process flow chart of the acid rolling unit in strip steel production is as follows figure 1 shown.

[0038] (1) The elongation setting value of the stretching and straightening phosphorus breaking machine is set according to the maximum value of 3%; the temperature of the pickling section is set at 80°C, and the three-stage pickling concentration control requirements are respectively 40 ± 20g / L, 120±20g / L and l60±20g / L; the rinse water temperature is set at 60...

Embodiment 2

[0045] In this embodiment, the steel grade group arrangement plan is 2200 tons.

[0046] Rolling oil brand: BONDERITE. Rolling oil type: L-RO 6021-HS. The emulsion is obtained after the rolling oil is diluted. Rolling Oil Type: Non-ionic steady state rolling oil. The composition of rolling oil is shown in Table 1. The physical and chemical indicators of rolling oil are shown in Table 2.

[0047] Cleaning agent brand: BONDERITE. The cleaning agent model is: L-AD 391, and the parameters are shown in Table 3. Part of the process flow chart of the acid rolling unit in strip steel production is as follows figure 1 shown.

[0048] (1) The elongation setting value of the stretching and straightening phosphorus breaking machine is set according to the maximum value of 3%; the temperature of the pickling section is set at 80°C, and the three-stage pickling concentration control requirements are respectively 40 ± 20g / L, 120±20g / L and l60±20g / L; the rinse water temperature is set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com