Reciprocating type vibration device for reducing soot formation blockage of SCR denitration catalyst, and working method thereof

A denitrification catalyst and vibration device technology, applied in the field of SCR denitrification, to achieve low investment and operating costs, improve the serious problem of catalyst fouling and blockage, good environmental protection and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

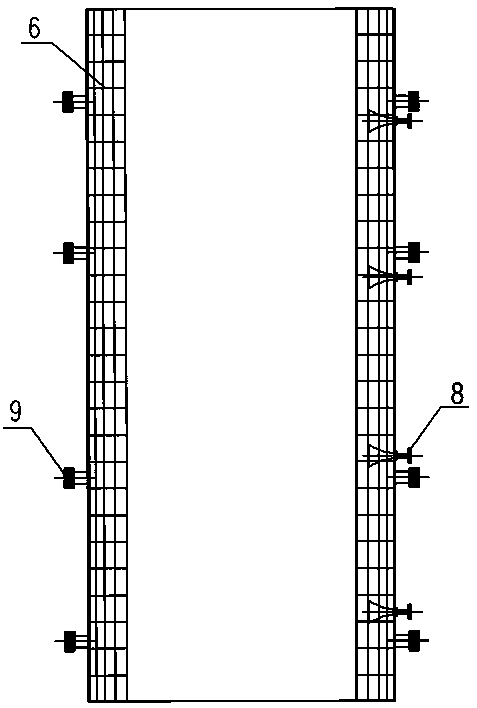

[0017] see Figure 1 to Figure 2 , In the present embodiment, a reciprocating vibrating device for reducing fouling of SCR denitrification catalyst, SCR denitrification system includes inlet flue 1, ammonia injection grid 2, rectification device 3 and SCR reactor 4, inside SCR reactor 4 Catalyst layer 5 is installed, and the upper part of SCR reactor 4 is provided with anti-ash net 6, and anti-ash net 6 is connected with driving device 7 and vibrating device 9, and the upper part of anti-ash net 6 is provided with sonic soot blower 8, and driving device 7 is used to realize the anti-ash net 6 to move up and down, and the vibrating device 9 is connected with the anti-ash net 6 through a transmission mechanism, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com