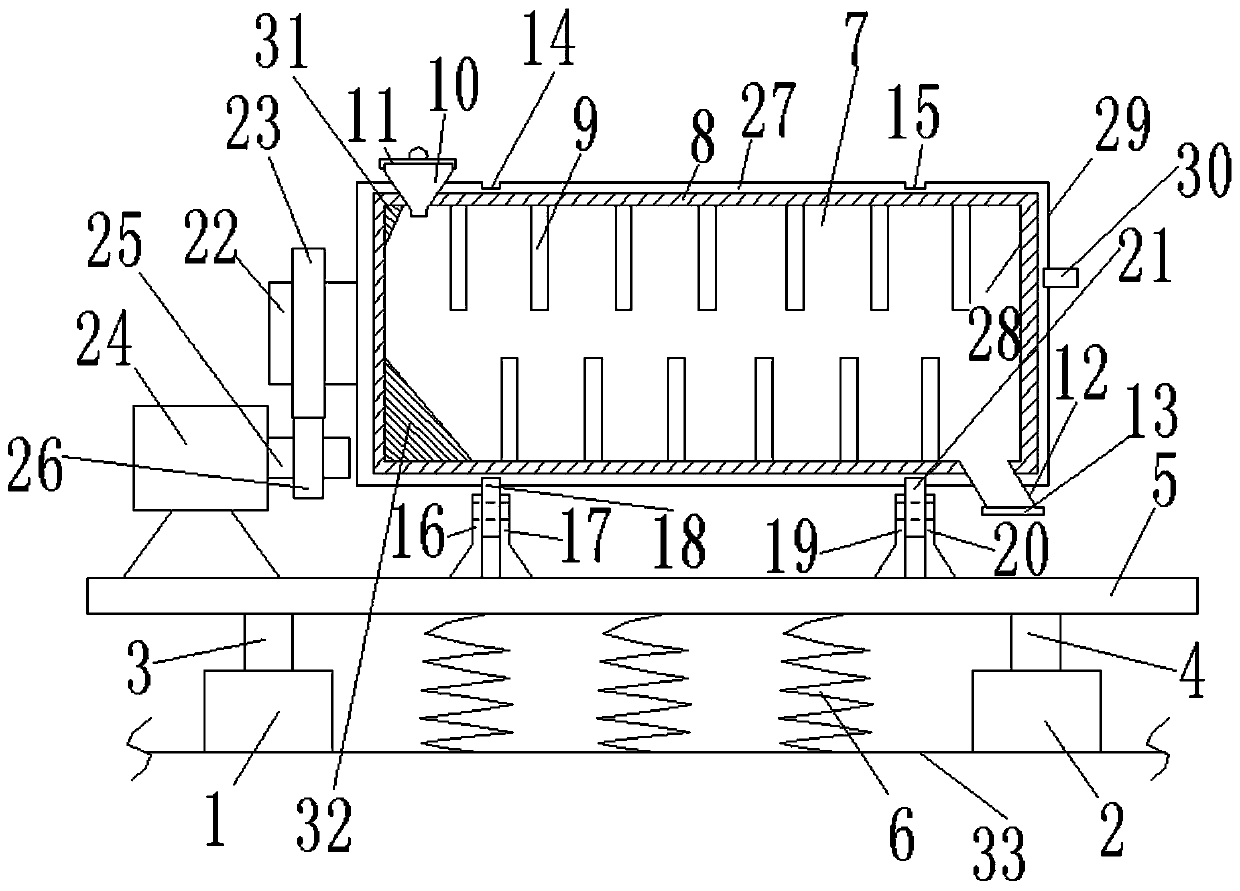

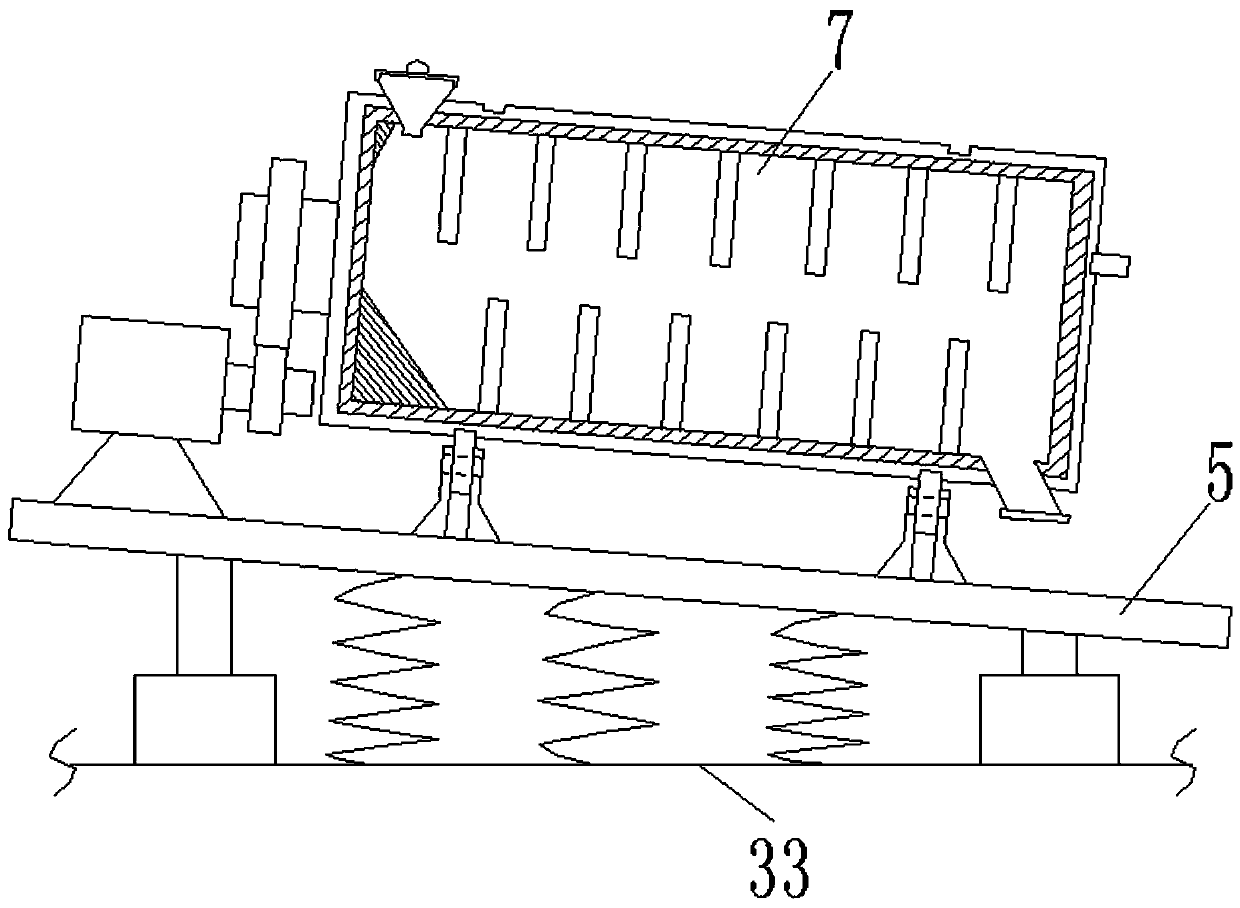

Teabag production apparatus and teabag production method

A production device, tea bag technology, applied in the direction of tea substitutes, etc., can solve the problems of long time, unfavorable uniform frying, cumbersome operation, etc., and achieve the effects of short time, waste reduction, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Adopt the method for preparing tea in bag by above-mentioned tea in bag production device, comprise the following steps:

[0036] (1) Rinse the cassia seeds with water and drain them, then dry the drained cassia seeds in the air, then stir-fry the dried cassia seeds in the frying equipment until the outer burnt and the inner are slightly burnt, then cool to room temperature to make Fried cassia seeds were obtained, and the fried cassia seeds were crushed into 8 meshes to obtain crushed fried cassia seeds;

[0037] (2) Clean and drain the wild chrysanthemums, then dry the drained wild chrysanthemums in a dryer at 40°C for 3 hours, and crush the dried wild chrysanthemums into 10 meshes to obtain crushed wild chrysanthemums ;

[0038] (3) Clean the stevia and drain it, then dry the drained stevia in a dryer at 120°C for 50 minutes, and crush the dried stevia into 12 meshes to obtain crushed stevia ;

[0039] (4) Mix the crushed and fried cassia seeds in step (1), the cr...

Embodiment 2

[0041] Adopt the method for preparing tea in bag by above-mentioned tea in bag production device, comprise the following steps:

[0042] (1) Rinse the cassia seeds with water and drain them, then dry the drained cassia seeds in the air, then stir-fry the dried cassia seeds in the frying equipment until the outer burnt and the inner are slightly burnt, then cool to room temperature to make Fried cassia seeds are obtained, and the fried cassia seeds are crushed into 10 meshes to obtain crushed fried cassia seeds;

[0043] (2) Clean and drain the wild chrysanthemum, then dry the drained wild chrysanthemum in a dryer at 50°C for 2 hours, and crush the dried wild chrysanthemum into 8 meshes to obtain crushed wild chrysanthemum ;

[0044] (3) Clean the stevia and drain it, then dry the drained stevia in a dryer at 110°C for 60 minutes, and crush the dried stevia into 10 meshes to obtain crushed stevia ;

[0045] (4) Mix the crushed and fried cassia seeds in step (1), the crushed ...

Embodiment 3

[0047] Adopt the method for preparing tea in bag by above-mentioned tea in bag production device, comprise the following steps:

[0048] (1) Rinse the cassia seeds with water and drain them, then dry the drained cassia seeds in the air, then stir-fry the dried cassia seeds in the frying equipment until the outer burnt and the inner are slightly burnt, then cool to room temperature to make Obtain fried cooked cassia seeds, and crush the fried cooked cassia seeds into 12 meshes to obtain crushed fried cooked cassia seeds;

[0049] (2) Clean and drain the wild chrysanthemum, then dry the drained wild chrysanthemum in a dryer at 45°C for 2.4 hours, and crush the dried wild chrysanthemum into 12 meshes to obtain crushed wild chrysanthemum chrysanthemum;

[0050] (3) Clean the stevia and drain it, then dry the drained stevia in a dryer at 115°C for 55 minutes, and crush the dried stevia into 8 meshes to obtain crushed stevia ;

[0051] (4) Mix the crushed and fried cassia seeds i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com