Experimental device for liquid metal magnetohydrodynamic generation research and using method thereof

A magnetofluidic power generation and liquid metal technology, which is used in measuring devices, measuring electricity, educational appliances, etc., can solve the problems of insufficient research investment, limited experimental parameter conditions for flexible changes, and lack of liquid metal magnetofluidic power generation channels. Research, manufacture and maintain the effect of accurate and reliable experimental basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

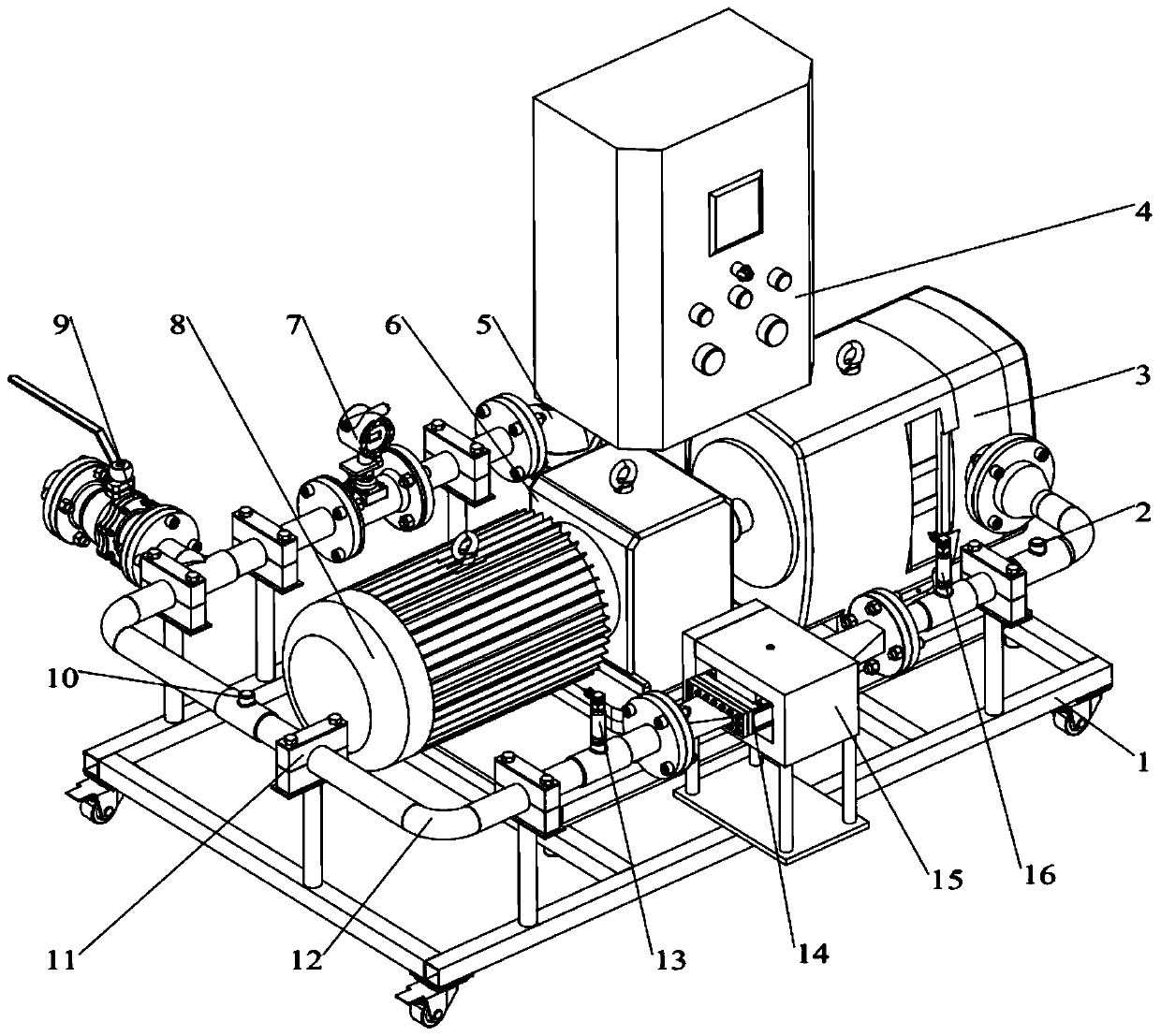

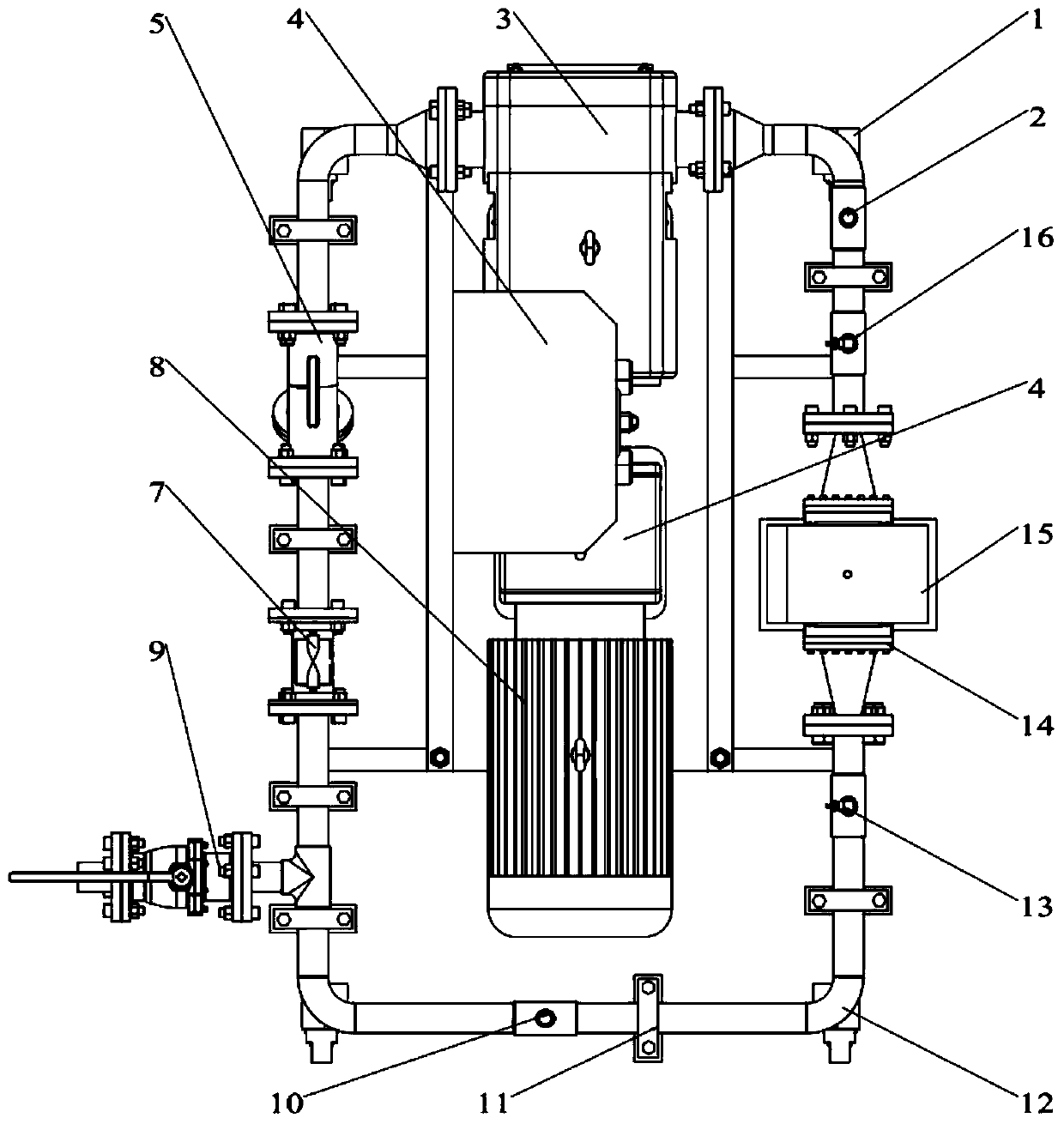

[0035] first embodiment ,refer to figure 1 and 2 , an example of an experimental device designed by the present invention for liquid metal magnetic fluid power generation research and its use method, including: pump head 3, filter 5, turbine flowmeter 7, recovery ball valve 9, pipeline 12, pre-pressure variable Transmitter 13, power generation channel 14, magnetic gathering device 15, post pressure transmitter 16.

[0036] The pipeline 12 connects the inlet of the pump head 3 of the lobe rotor pump, the filter 5, the turbine flowmeter 7, the recovery ball valve 9, the power generation channel 14 and the outlet of the pump head 3 of the rotor lobe pump through flanges to form a circulation pipe together. road.

[0037] The front pressure transmitter 13 and the rear pressure transmitter 16 are respectively installed on the pipelines at the inlet and outlet of the power generation channel 14 . The magnetic collecting device 15 surrounds the periphery of the generating channe...

no. 2 example

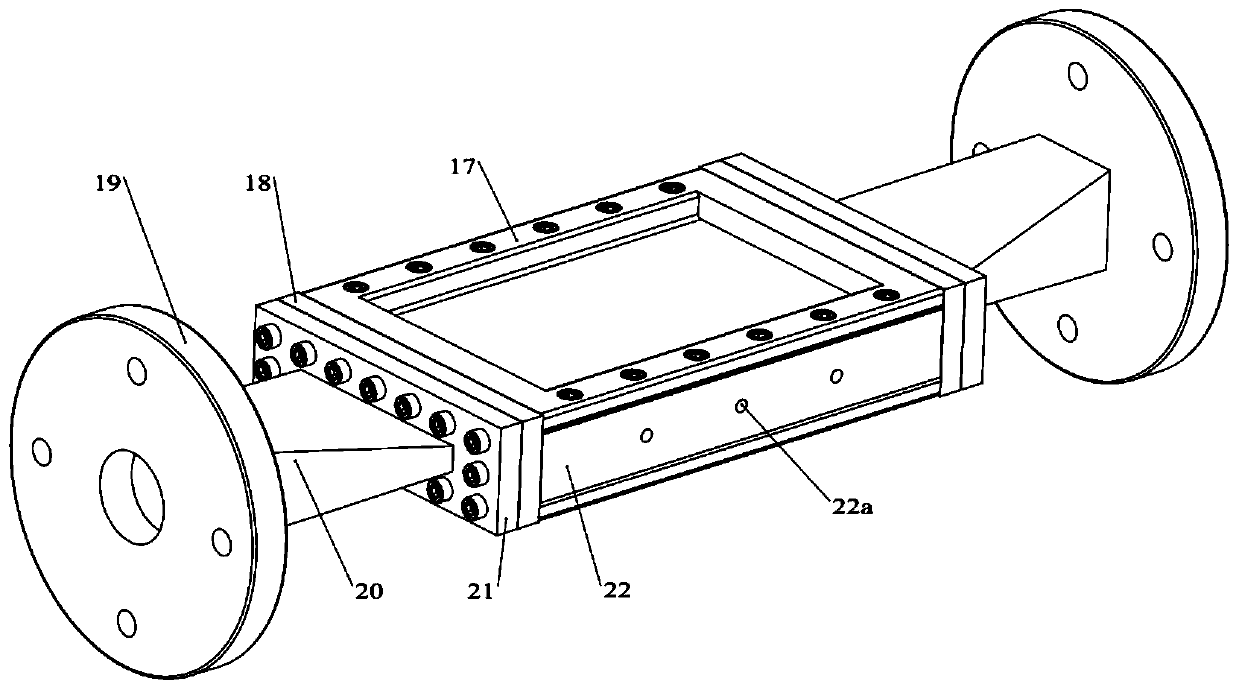

[0041] second embodiment ,refer to image 3 and 4 , the power generation channel 14 is composed of an insulating channel plate 17, an intermediate insulating flange 18, a connecting flange 19, a transition flange 21 and an electrode 22. A pair of insulating channel plates 17 and a pair of electrodes 22 are connected by screws, forming a square shape in the middle When the liquid metal magnetic fluid flows through the channel, an induced electromotive force will be generated under the action of the magnetic field. The intermediate insulating flanges 18 are divided into two groups, which are symmetrically arranged at both ends of the electrode 22 . The connecting flange 19, the reducer pipe 20 and the transition flange 21 are sealed and fixed together sequentially. The transition flange 21, the intermediate insulating flange 18, and the insulating channel plate 17 are fixed together. A wiring hole 22a is opened on the outer end surface of the electrode, which is used for con...

no. 3 example

[0043] third embodiment ,refer to Figure 5 , the magnetic gathering device 15 is a structure with a square through hole in the middle, the upper and lower opposite sides of the square through hole are respectively fixed with an N pole magnet 15c and an S pole magnet 15d, and the electrode 22 and the insulating channel plate 17 are arranged on the N pole. In the gap between the pole magnet and the S pole magnet.

[0044] The magnetic gathering device 15 of this structure can be replaced with magnets of different strengths, and the influence of different magnetic field strengths on the characteristics of the power generation channel can be studied. In addition, during installation, since the power generation channel and the magnet are a separate design, it is convenient to replace magnets of different strengths in the progress of subsequent experiments, and to study the influence of different magnetic field strengths on the characteristics of the power generation channel. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com