Dry burning judgment method applied to PTC heating equipment

A heating equipment, dry burning technology, applied in the direction of thermometers, ohmic resistance heating, ohmic resistance heating circuit diagrams that use electrical/magnetic components directly sensitive to heat, etc., can solve problems such as increasing equipment costs, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

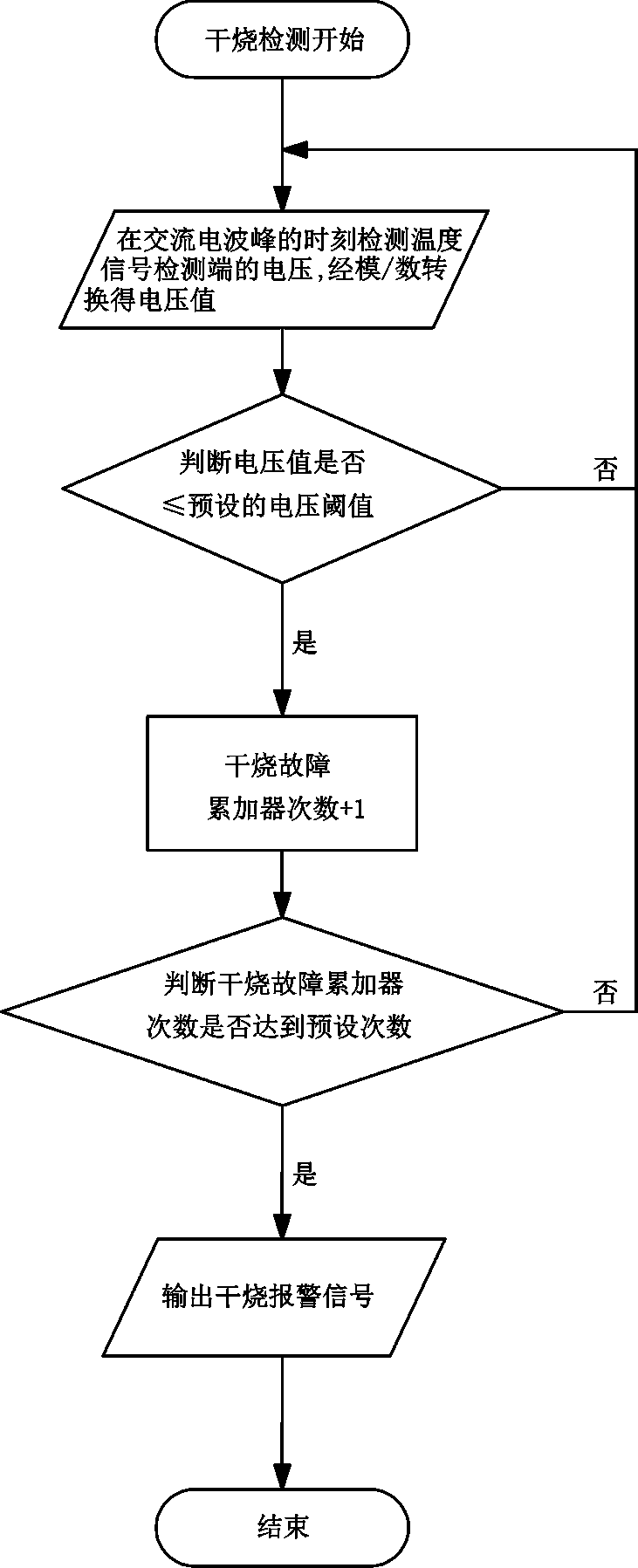

[0040] In the present embodiment, the dry burning judgment method applied to PTC heating equipment is characterized in that:

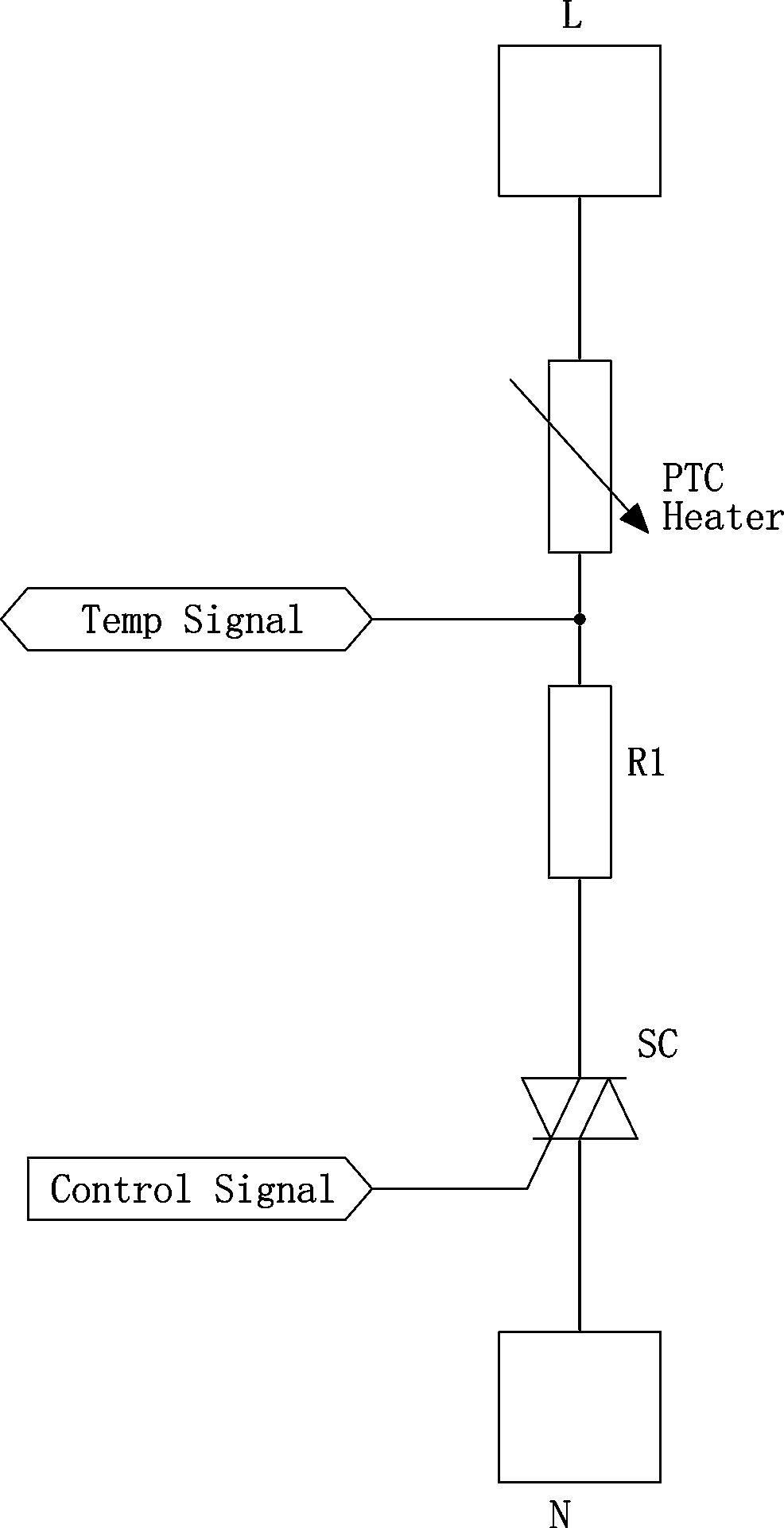

[0041] refer to figure 1 , connect the PTC heating device with the power line and the main control chip in the following way: one end of the PTC heating device (PTCheater) is connected to the live wire L, the other end of the PTC heating device is connected to the end of the resistor R1, and the other end of the resistor R1 is controlled by The silicon SC is connected to the neutral line N; the control pole of the thyristor SC is connected to the corresponding control signal output terminal of the main control chip (the main control chip is not shown in the figure), and the connection between the PTC heating device and the resistor R1 is used as a temperature signal The detection terminal (Temp Signal), the temperature signal detection terminal is connected to the corresponding signal input terminal of the main control chip;

[0042] The main control ...

Embodiment 2

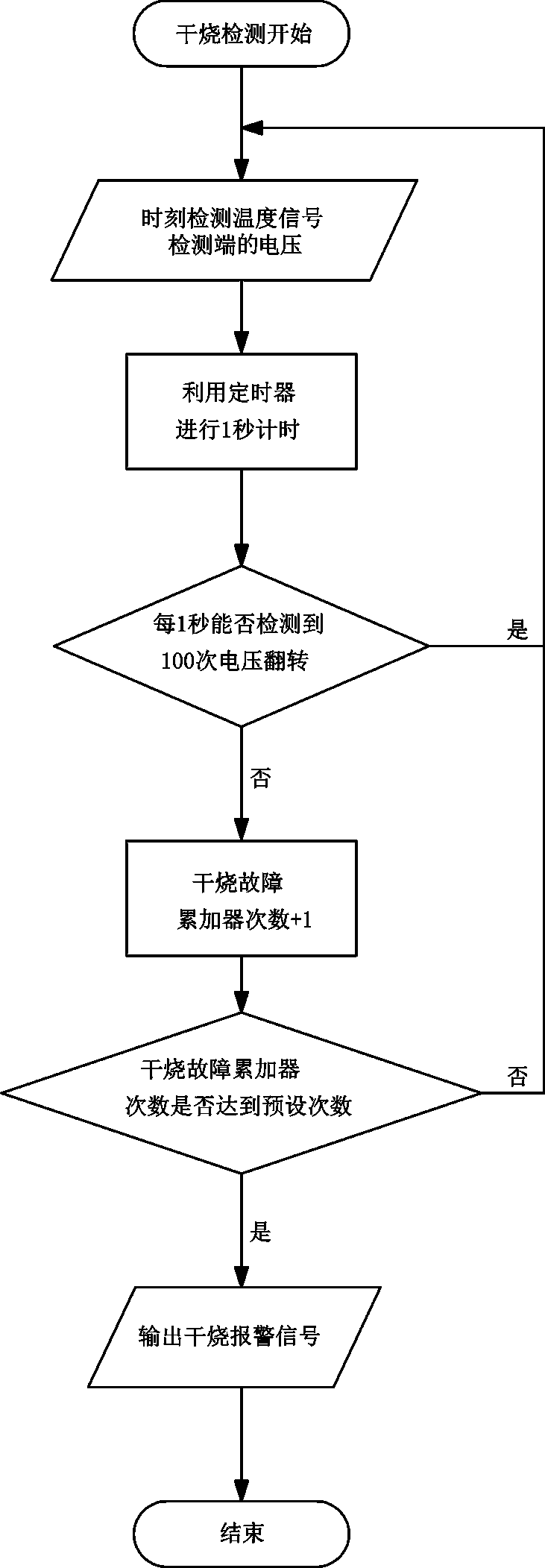

[0058] The circuit connection of this embodiment is the same as that of Embodiment 1. The difference from the embodiment is that in this embodiment, the main control chip does not have an analog / digital converter (that is, the main control chip does not have an analog / digital conversion function. For example, the main control chip can be the chip HT68F003 produced by Holtek. ), the steps to judge whether the PTC heating equipment is in a dry state are as follows:

[0059] (1') Detect the voltage of the temperature signal detection terminal at all times;

[0060] (2') Use the timer to count for 1 second, and judge whether a predetermined number of (such as 100) voltage reversals can be detected every 1 second;

[0061] If the predetermined number of voltage reversals cannot be detected, add 1 to the accumulator of dry burning faults, and enter step (3');

[0062] If a predetermined number of voltage reversals can be detected, return to step (1');

[0063] (3') Judging whethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com