Method for detecting sealing state of watertight door based on fiber bragg grating

A fiber grating and detection method technology, applied in the field of ships, can solve the problems of misjudgment or omission of detection, poor corrosion resistance and chemical stability, and poor anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

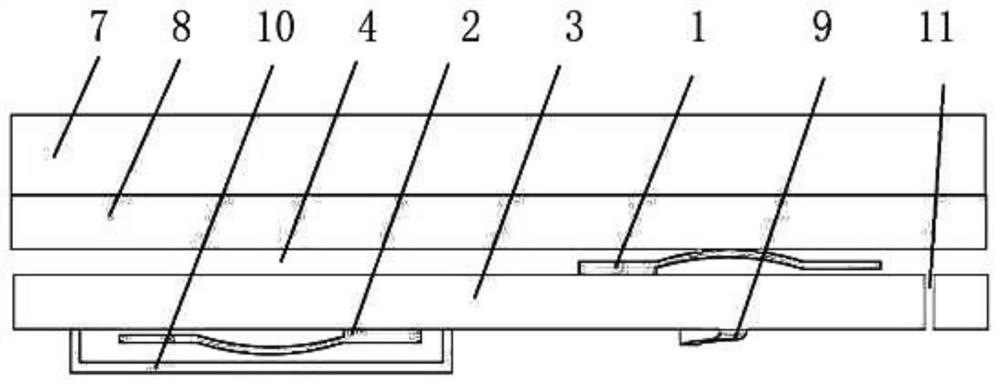

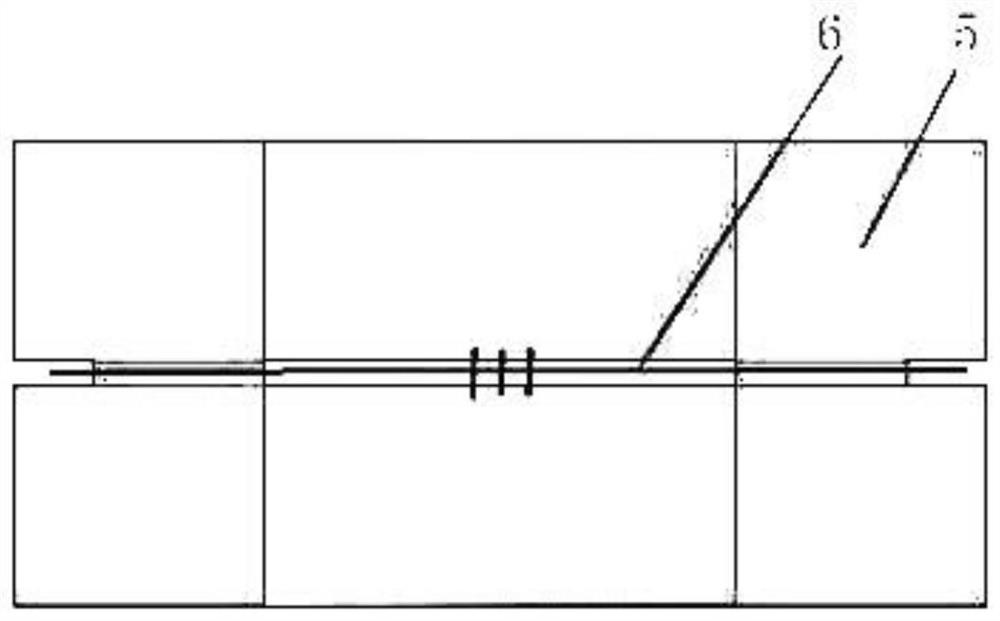

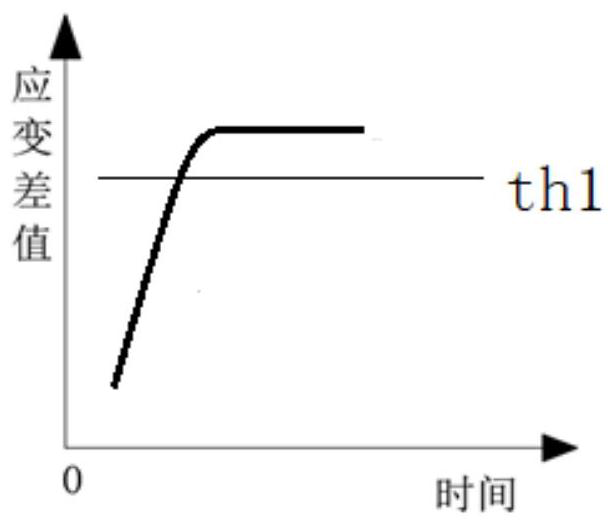

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. The content shown in each figure is only for understanding the technical content of the invention, and does not represent the actual scale and real shape of the product, wherein the same reference numerals indicate parts with the same structure or the same function but similar structure.

[0022] In this article, "parallel", "perpendicular", etc. are not strictly limited in the sense of mathematics and / or geometry, and they may also include errors understandable by those skilled in the art and allowed when manufacturing or using the product. In addition, "perpendicular" not only includes two objects being perpendicular to each other directly in space, but also perpendicular to each other when two objects are not touching in space. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com