Municipal pipeline mounting structure and construction method thereof

A technology for municipal pipelines and installation structures, which is applied in the sewer system, waterway system, water supply device, etc., can solve the problems of clogging the pipeline, inconvenient installation and disassembly, affecting the efficiency of emergency repair, etc., and achieve the effect of simple construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

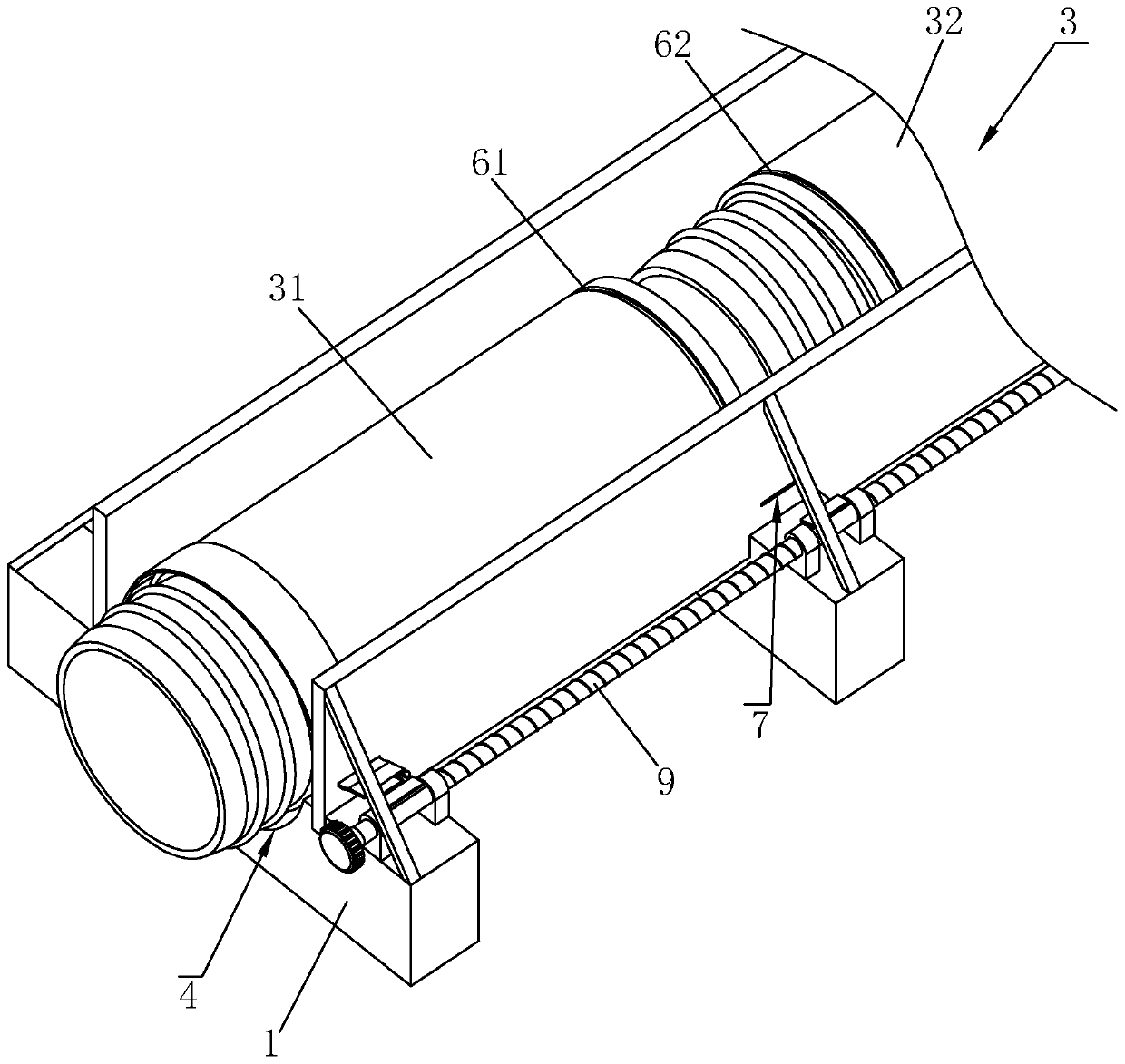

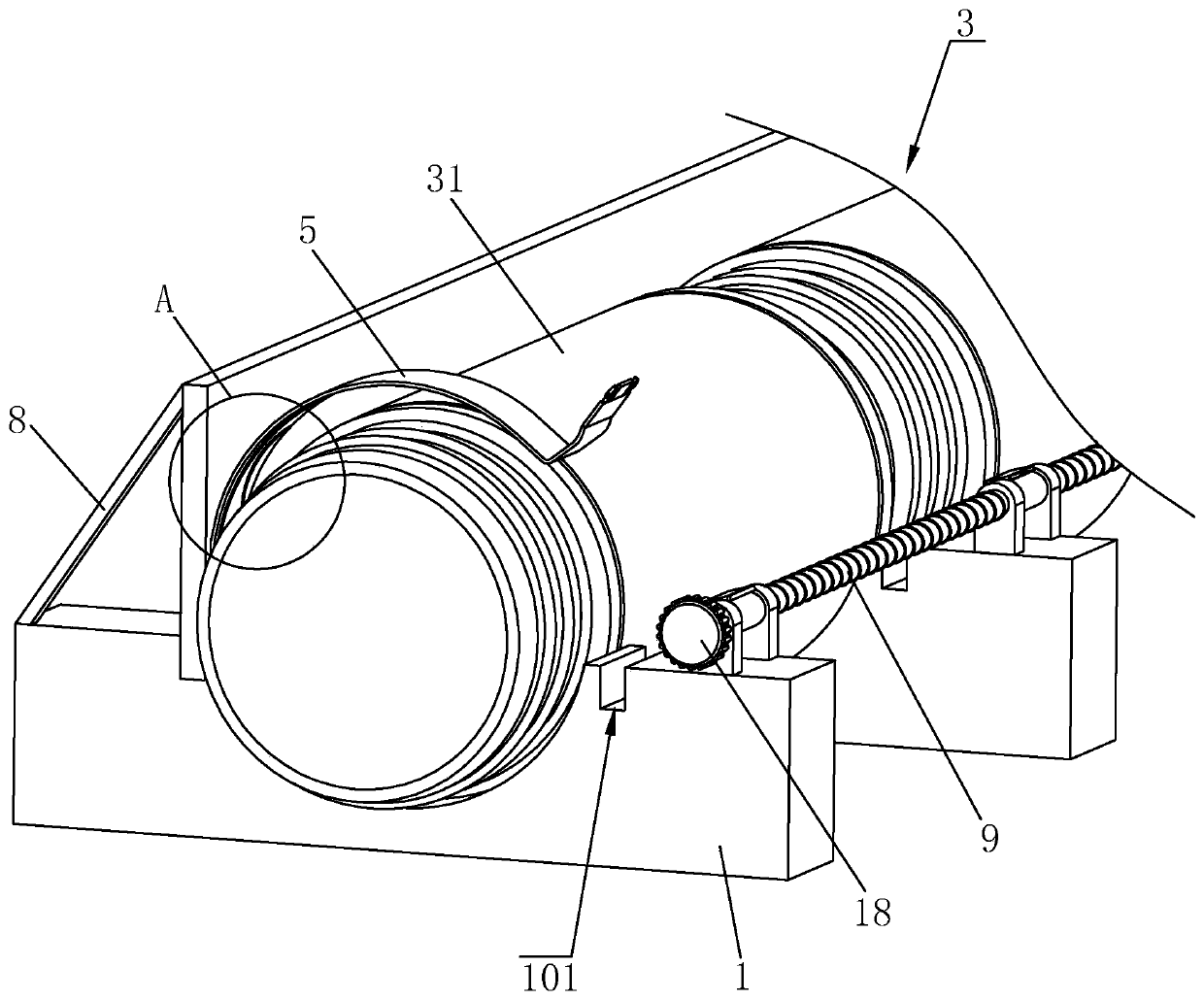

[0045] A municipal pipeline installation structure, referring to figure 1 and figure 2 , including several pipes 3 and a plurality of cuboid pipe bases 1 for supporting the pipes 3 arranged in the groove (not shown in the figure), the number of pipe bases 1 can be adjusted according to the actual length of the groove Adjust, and the pipe base 1 is distributed along the length direction of the groove.

[0046] refer to figure 2 and image 3, the upper surface of the pipe base 1 is provided with accommodating grooves 4 for the pipes 3 to accommodate and lock. Specifically, the two adjacent pipes 3 are respectively the first pipe 31 and the second pipe 32, and the first pipe 31 is close to the second pipe 31. One end of the second pipeline 32 is provided with an external thread, and the end of the second pipeline 32 near the first pipeline 31 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com