High-early-strength steel slag pervious concrete as well as preparation method and applications thereof

A technology of permeable concrete and early strength, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc. It can solve the problems of permeable concrete rolling, vibration, and affecting the construction period, etc., to achieve improved early strength performance and simple process , the effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

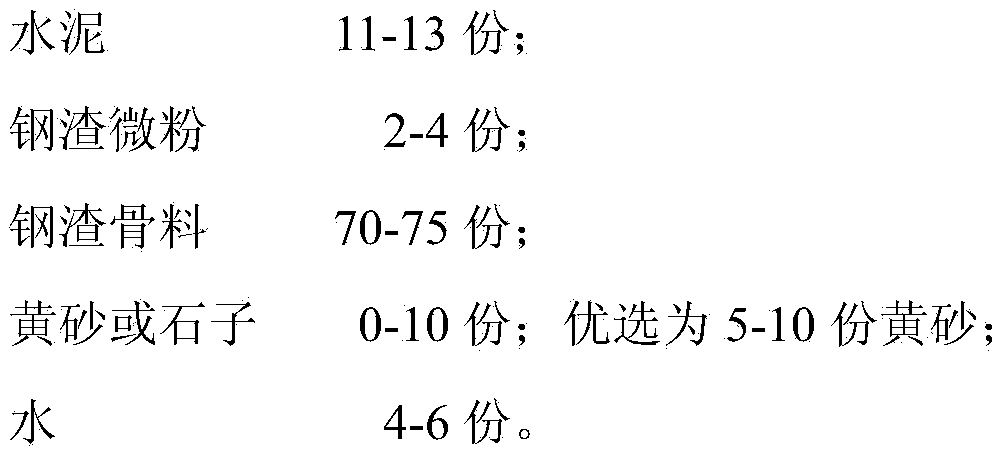

Method used

Image

Examples

Embodiment

[0033] The cement used in this example is P.O42.5 cement, and sand and stone meet the corresponding national standard requirements (in line with JGJ52-2006), which are common materials on the market.

[0034] Steel slag fine powder is converter steel slag fine powder and / or electric furnace steelmaking steel slag fine powder, and the steel slag fine powder has a specific surface area ≥ 360m 2 / kg, 45μm sieve residue ≤ 2%. Steel slag aggregate is a continuously graded aggregate within a certain particle size range.

[0035] The preparation method of the steel slag permeable concrete in this embodiment is to simply mix steel slag, sand and gravel and other aggregates according to the ratio in Table 1, then add cement and other powder materials and mix evenly, then add water and stir, and mix well, it can be prepared. Specifically include the following steps:

[0036] 1) fully mixing the powder material, which includes cement and steel slag micropowder;

[0037] 2) mixing the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com