Vermicular graphite cast iron cooker and production method thereof

A technology of vermicular graphite cast iron and its production method, which is applied in the field of metal casting, can solve problems such as low strength, low toughness, and poor plasticity, and achieve the effect of high strength and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

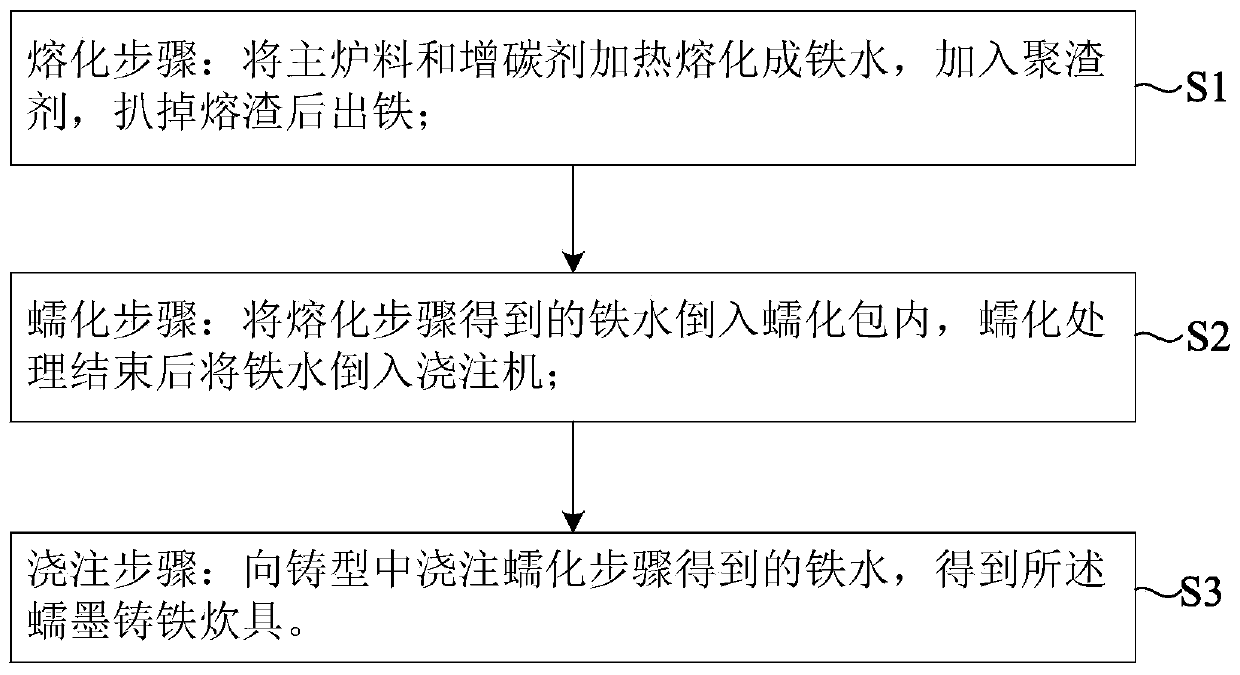

Method used

Image

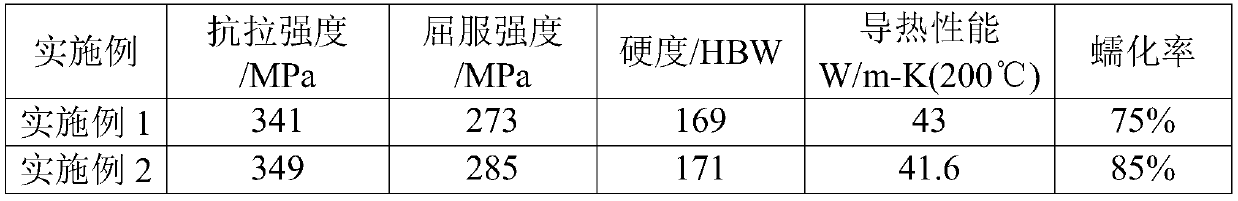

Examples

Embodiment 1

[0062] The production of embodiment 1 vermicular graphite cast iron pan support

[0063] (1) Melting step:

[0064] Add 200kg of pig iron with grade Q10 to the bottom of the electric furnace, add 24kg of recarburizer on it, and then add 600kg of carbon steel scrap and recycled materials one after another. Increase the power of the electric furnace to speed up the melting. For the undissolved carburant, after the carburant is completely dissolved, add 10kg of silicon carbide. After the silicon carbide is dissolved, add 2.5kg of slag accumulator to cover the molten iron, and add the remaining 400kg of slag accumulator to the molten iron. For pig iron of the Q10 brand, the pig iron block is completely melted and then the slag is removed for slagging and refining.

[0065] Add 2.5kg of slagging agent to the molten iron for the first slagging and first refining. The operation takes about 2-3 minutes. After the first slagging and first refining, carry out slag removal.

[0066] Co...

Embodiment 2

[0077] The production of embodiment 2 vermicular graphite cast iron hob

[0078] (1) Melting step:

[0079] Add 130kg of pig iron with grade Q10 to the bottom of the electric furnace, add 16kg of carburizer on top of it, and then add 400kg of carbon steel scrap and 300kg of recycled material one after another. Increase the power of the electric furnace to speed up melting. Observe whether there is any undissolved recarburizer. After the recarburizer is completely dissolved, add 10kg of silicon carbide. After the silicon carbide is dissolved, add 2.5kg of slag accumulator to cover the molten iron, and add successively to the slag accumulator covering the molten iron. The remaining 270kg of pig iron of the Q10 brand, after the pig iron block is completely melted, the slag is removed for slagging and refining.

[0080] Add 2.5kg of slagging agent to the molten iron for the first slagging and first refining. The operation takes about 2-3 minutes. After the first slagging and firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com