A kind of wetting type dust suppressant for road dust and preparation method thereof

A dust suppressant and road technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of road dust wettability without example, the road surface cannot meet the long-term effective dust suppression, affecting the pH of the dust suppressant, etc. Long-lasting moisturizing performance, improved dust suppression efficiency, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

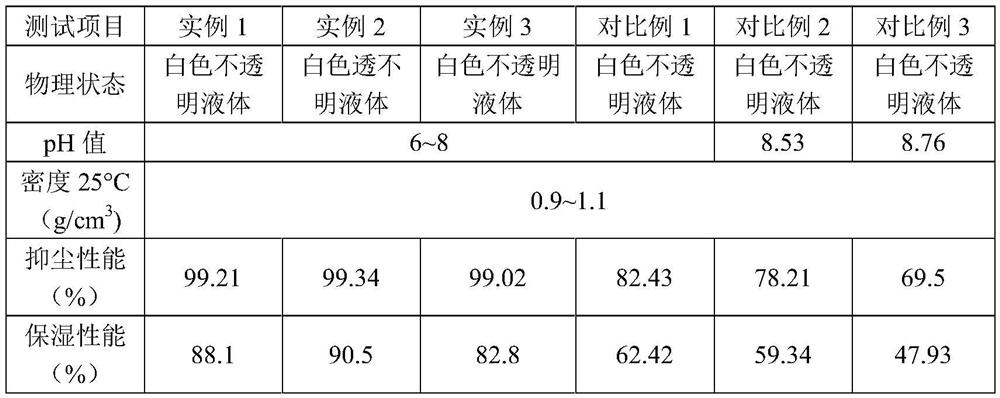

Examples

Embodiment 1

[0037] A wetting type dust suppressant is composed of the following components by mass percentage: CaCl 2 : 15%, Span-80: 0.2%, Glycerin: 0.5%, Methylcellulose: 1%, Sodium dodecylbenzenesulfonate: 0.4%, Sodium lactate: 0.5%, Urea: 0.5%, Water: 81.9% .

[0038] Its preparation method is:

[0039] (1) The water is divided into three parts of A of 315g, B of 252g, and C of 252g, A is heated to 50°C, and B and C are heated to 40°C;

[0040] (2) Mix 2g of Span-80, 10g of methylcellulose and 150g of CaCl 2 After mixing evenly, mix with water in part A, keep stirring for 40min at a rotating speed of 100rpm / min, and then cool to room temperature to obtain aqueous solution a;

[0041] (3) 5g sodium lactate, 5g glycerol and 5g urea are mixed with B part water, after insulation stirring 40min under rotating speed 100rpm / min, add 4g sodium dodecylbenzenesulfonate, add C part water again, obtain aqueous solution b;

[0042] (4) Stir the aqueous solution b at a rotational speed of 100 r...

Embodiment 2

[0054] A wetting type dust suppressant is composed of the following components by mass percentage: CaCl 2 : 10%, Span-80: 0.1%, Glycerin: 2%, Xanthan gum: 0.7%, Sodium fatty acid ethyl ester sulfonate: 0.3%, Sodium lactate: 0.2%, Urea: 0.9%, Water: 85.8%.

[0055] Its preparation method is:

[0056] (1) The water is divided into three parts of A of 286g, B of 286g, and C of 286g, A is heated to 60°C, and B and C are heated to 50°C;

[0057](2) Mix 1g of Span-80, 7g of xanthan gum and 100g of CaCl 2 After mixing evenly, mix with the water of part A, keep stirring for 30min at a rotating speed of 300rpm / min, and then cool to room temperature to obtain aqueous solution a;

[0058] (3) 2g sodium lactate, 20g glycerol and 9g urea are mixed with B part water, after insulation stirring 30min under rotating speed 300rpm / min, add 3g fatty acid ethyl ester sulfonate sodium, add C part water again, obtain aqueous solution b;

[0059] (4) Stir the aqueous solution b at a rotational spe...

Embodiment 3

[0062] A wetting type dust suppressant is composed of the following components by mass percentage: CaCl 2 : 5%, Span-80: 0.6%, Glycerin: 1%, Polyacrylamide: 1%, Sodium oleamide: 0.5%: Sodium lactate: 0.2%, Urea: 2%, Water: 89.7%.

[0063] Its preparation method is:

[0064] (1) The water is divided into three parts of A of 280g, B of 308g, and C of 309g, A is heated to 55°C, and B and C are heated to 45°C;

[0065] (2) Mix 6g of Span-80, 10g of polyacrylamide and 50g of CaCl 2 After mixing evenly, mix with the water of part A, keep stirring for 35min at a rotating speed of 200rpm / min, and then cool to room temperature to obtain aqueous solution a;

[0066] (3) 2g sodium lactate, 10g glycerol and 20g urea are mixed with B part water, after insulation stirring 35min under rotating speed 200rpm / min, add the sodium oleamide of 5g, then add C part water, obtain aqueous solution b;

[0067] (4) Stir the aqueous solution b at a rotational speed of 130 rpm / min, add the aqueous solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com