Bletilla striata oligosaccharide extracted from bletilla striata rhizomes and preparation method of bletilla striata oligosaccharide

A technology of oligosaccharides and stems of Bletilla striata, which is applied to the preparation of oligosaccharides and sugar derivatives, chemical instruments and methods, etc., and can solve problems that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

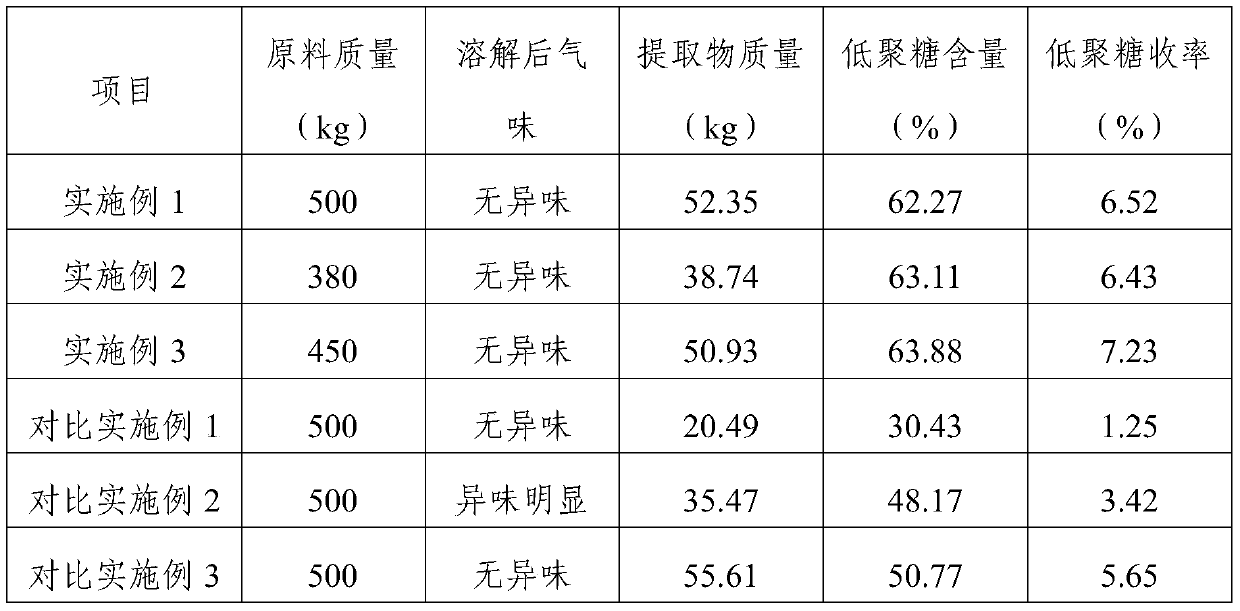

Examples

Embodiment 1

[0027] A method for extracting bletilla striata oligosaccharides from rhizomes of bletilla striata, comprising the following steps:

[0028] (1) Wash 500kg of bletilla striata stems and cut them into 1-2mm thin slices; perform 3 extractions, add 3000L deionized water each time according to the ratio of solid to liquid ratio 1g: 6ml, stir and heat at 40°C for 3h; combine the extracts , and centrifuged to obtain the stem block extract of Bletilla striata;

[0029] (2) Pass the bletilla striata stem block extract at a speed of 1.5Bv / h through a neutral alumina column with a column volume of 2m3 and a column height-to-inner diameter ratio of 10:1 to obtain effluent A, wherein the neutral alumina column uses Dry column packing, the mesh number of alumina is 60-80 mesh;

[0030] (3) Concentrate the effluent A to Brix 15° in vacuum, pass through the cross-linked sephadex column G-15 with a column volume of 2m3 and a column height-to-inner diameter ratio of 15:1 at a speed of 2Bv / h, ...

Embodiment 2

[0035] The method for extracting bletilla striata oligosaccharides from bletilla striata rhizome comprises the following steps:

[0036] (1) Wash 380kg of bletilla striata stems and cut them into 1-2mm thin slices; perform 3 extractions, add 1900L deionized water each time according to the ratio of solid-liquid ratio 1g: 5ml, stir and heat at 40°C for 3h; combine the extracts , and centrifuged to obtain the stem block extract of Bletilla striata;

[0037] (2) Pass the bletilla striata stem extract at a rate of 1Bv / h through a neutral alumina column with a column volume of 2m3 and a column height-to-inner diameter ratio of 10:1 to obtain effluent A, wherein the neutral alumina column is dry Column packing by method, the mesh number of alumina is 60-80 mesh;

[0038] (3) Concentrate the effluent A to Brix 17° in vacuo, and pass through the cross-linked sephadex column G-15 with a column volume of 1.52m and a column height to internal diameter ratio of 10:1 with a speed of 1.5Bv...

Embodiment 3

[0043] The method for extracting bletilla striata oligosaccharides from bletilla striata rhizome comprises the following steps:

[0044] (1) Wash 450kg of bletilla striata stems and cut them into 1-2mm thin slices; extract 3 times, add 2475L deionized water each time according to the ratio of solid-liquid ratio 1g: 5.5ml, stir and heat at 46°C for 3h; combine and extract solution, centrifuged and filtered to obtain the stem block extract of Bletilla striata;

[0045] (2) Pass the bletilla striata stem block extract at a speed of 1.2Bv / h through a neutral alumina column with a column volume of 2m3 and a column height-to-inner diameter ratio of 10:1 to obtain effluent A, wherein the neutral alumina column uses Dry column packing, the mesh number of alumina is 60-80 mesh;

[0046] (3) Concentrate the effluent A to Brix 16° in vacuum, pass through the cross-linked sephadex column G-15 with a column volume of 1.8m3 and a column height-to-inner diameter ratio of 12:1 at a speed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com