Fermentation method for improving shrimp sauce quality

A fermentation method and technology of shrimp paste, which is applied in the field of fermentation to improve the quality of shrimp paste, can solve the problems of uneven microorganisms, and achieve the effect of low biogenic amine content, purple color and delicious taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

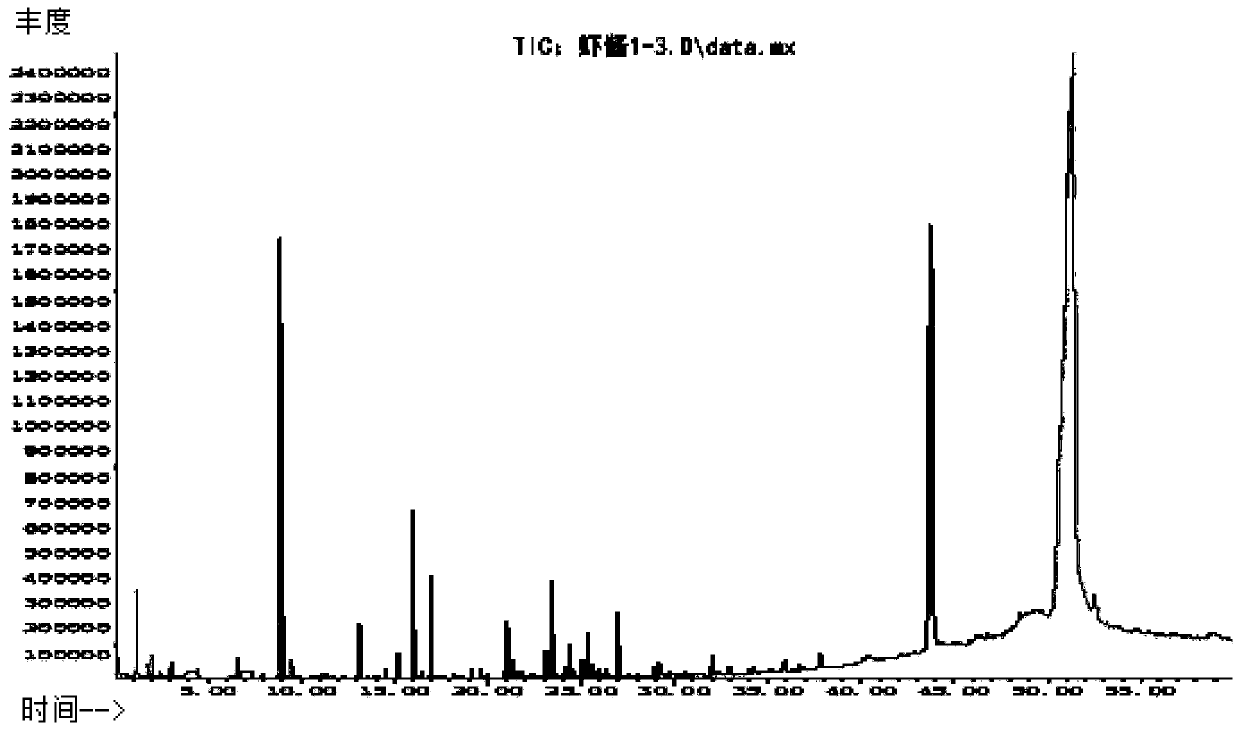

Image

Examples

Embodiment 1

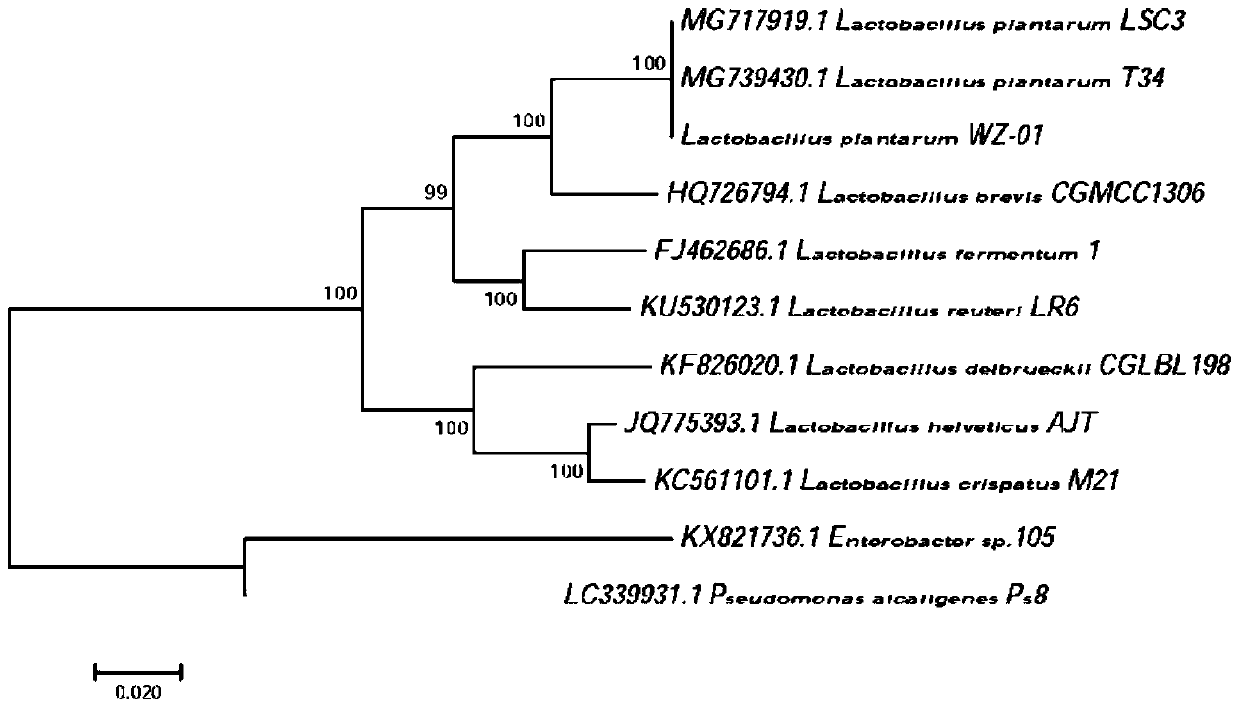

[0101] 1. Seed preparation of Lactobacillus plantarum and Monascus purple

[0102] (1) Lactobacillus plantarum CGMCC No.13338 was inoculated into the lactic acid bacteria seed culture medium, and cultured at 35° C. for 48 hours to obtain Lactobacillus plantarum seed liquid;

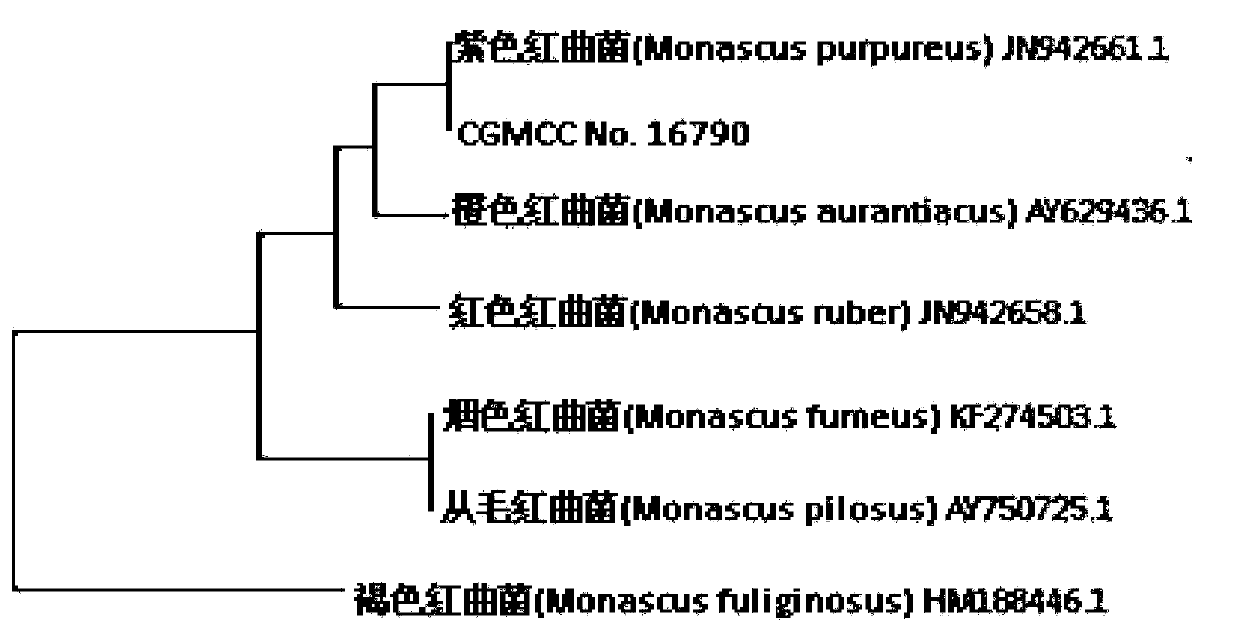

[0103] (2) Monascus purple CGMCC No.16790 was inoculated into the Monascus seed medium, and cultured at 28° C. for 72 hours to obtain a Monascus seed liquid;

[0104] 2. Preparation of shrimp paste

[0105] (1) Processing of raw materials - 1kg of fresh raw materials of hairy shrimp, remove the sundries, clean it, drain the water, then use a meat grinder at 2000 rpm for 20 minutes, and then use a colloid mill at a fineness of 50 microns , fine crushing cycle 10 times.

[0106] (2) batching-add its weight 1% glucose, 1% onion powder in the pulverized shrimp;

[0107] (3) Sterilization—use an autoclave to keep the shrimp body at 105°C for 20 minutes;

[0108] (4) Inoculation—into the sterilized and cool...

Embodiment 2

[0113] One, the seed preparation of Lactobacillus plantarum and Monascus purple bacterium, with embodiment 1.

[0114] 2. Preparation of shrimp paste

[0115] (1) Processing of raw materials - 1 kg of frozen hairy shrimp raw materials, after thawing, remove the sundries, clean it, drain the water, then use a meat grinder at 2000 rpm for 20 minutes, and then use a colloid mill to grind at 50 microns. degree, fine crushing cycle 10 times.

[0116] (2) batching-add its weight 2% glucose, 1.5% onion powder in the pulverized shrimp;

[0117] (3) Sterilization—use an autoclave to keep the shrimp body at 105°C for 20 minutes;

[0118] (4) Inoculation—into the sterilized and cooled shrimp, insert 8% plantarum seed liquid and 12% Monascus purple seed liquid;

[0119] (5) Fermentation—add 10% salt by weight to the inoculated shrimp, and ferment for 12 days at 30°C;

[0120] (6) Sterilization—keep the fermented shrimp paste at 95°C for 4 hours.

[0121] The prepared shrimp paste has...

Embodiment 3

[0123] One, the seed preparation of Lactobacillus plantarum and Monascus purple bacterium, with embodiment 1.

[0124] 2. Preparation of shrimp paste

[0125] (1) Processing of raw materials - 5 kg of frozen raw shrimp raw materials, remove sundries after thawing, clean them, drain the water, then use a meat grinder to grind coarsely at 2000 rpm for 20 minutes, and then use a colloid mill to grind finely at 50 microns. degree, fine crushing cycle 10 times.

[0126] (2) batching-add its weight 1% glucose, 2% onion powder in the pulverized shrimp;

[0127] (3) Sterilization—use an autoclave to keep the shrimp body at 105°C for 20 minutes;

[0128] (4) Inoculation—into the sterilized and cooled shrimp, insert 8% Lactobacillus plantarum seed liquid and 8% Monascus purple seed liquid;

[0129] (5) Fermentation—add 12% salt of its weight in the inoculated shrimp, and ferment for 15 days at 30° C.;

[0130] (6) Sterilization—keep the fermented shrimp paste at 90°C for 4 hours.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com