Easily-torn film, multilayer film, packaging material, and container

An easy-to-tear, multi-layer film technology, applied in the direction of rigid containers, packaging, containers, etc., can solve the problems of packaging materials such as unsealing and leakage, and achieve the effect of excellent linear cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0139] Examples are given below to describe the present invention more specifically. Materials, usage-amounts, ratios, processing contents, processing procedures, and the like shown in the following examples can be appropriately changed as long as they do not deviate from the spirit of the present invention. Therefore, the scope of protection of the present invention is not limited to the specific examples shown below.

[0140]

[0141] >

[0142] Add 7.8 g of sodium hypophosphite monohydrate and 4.0 g of sodium acetate to 8.9 kg of adipic acid, heat and melt at 170°C under 0.1 MPaA in the reaction tank, and slowly add it dropwise over 2 hours while stirring the contents m-xylylenediamine 8.2kg, the temperature was raised to 250°C. After the temperature was raised, the pressure was gradually lowered to 0.08 MPaA over 1 hour, and maintained for 0.5 hours. After completion of the reaction, the contents were taken out in the form of strands, pelletized with a pelletizer, and...

Embodiment 1

[0182] In Example 1, it carried out similarly except having changed the kind and compounding quantity of polyamide A and polyamide B, and the residence time in a molding machine as shown in Table 1 or Table 2.

Embodiment 3

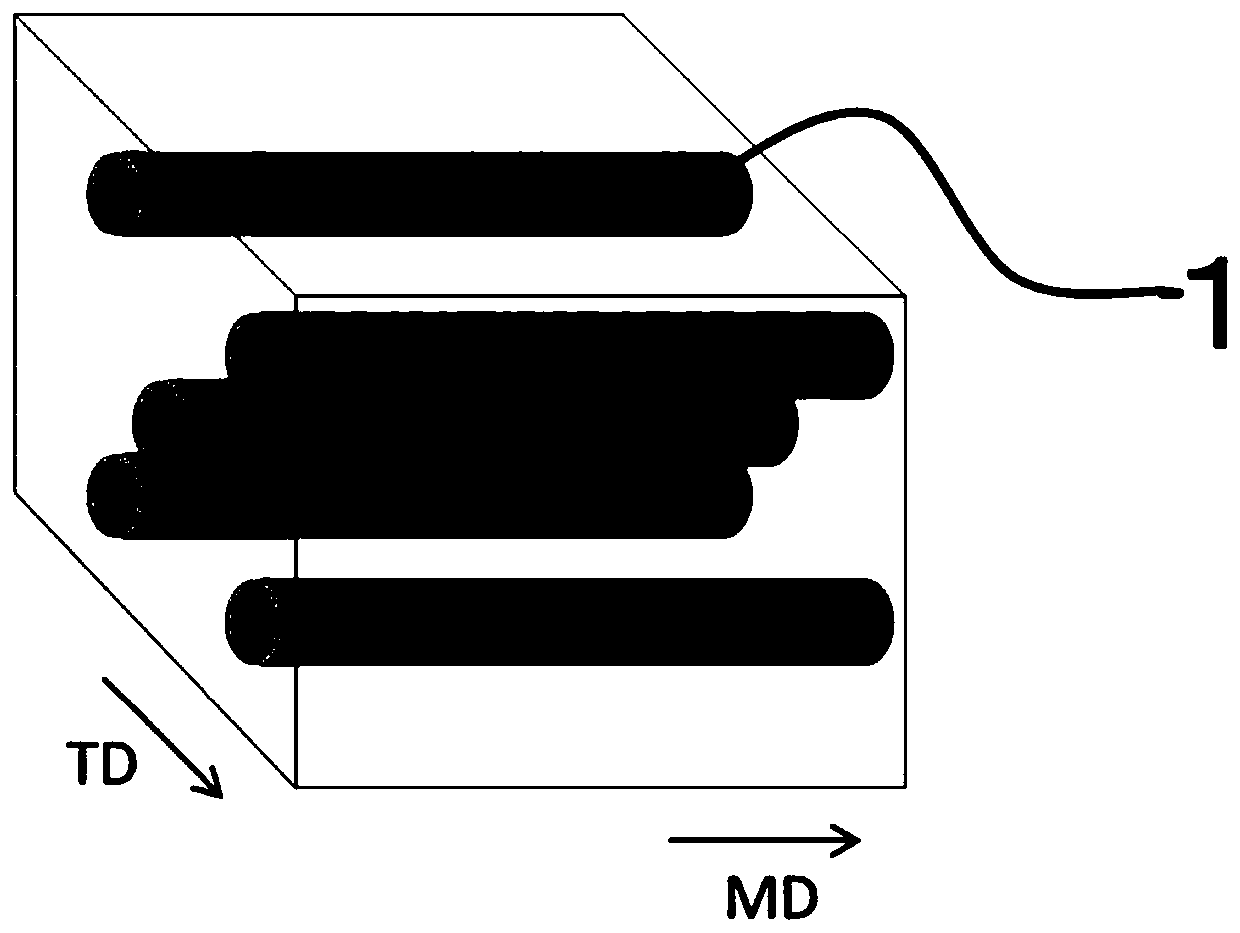

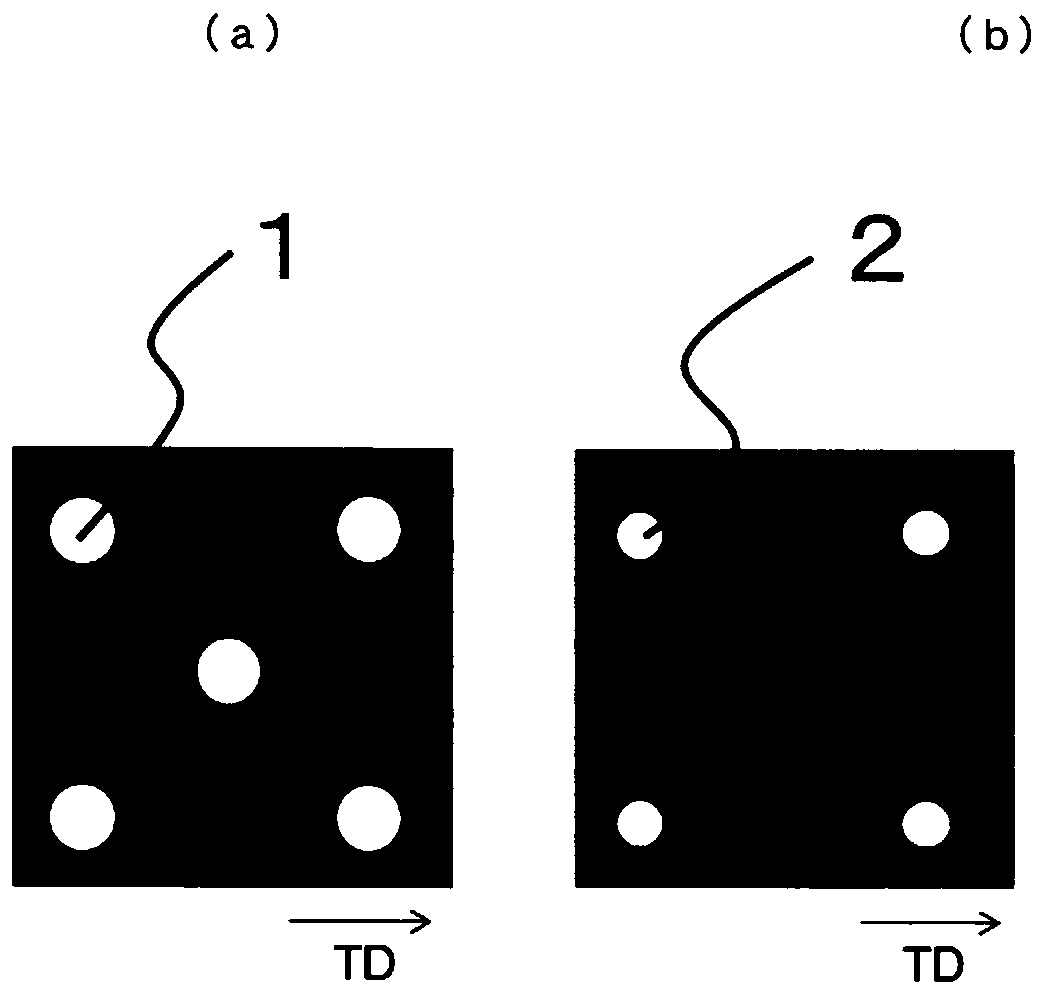

[0183] Regarding Example 3, the sample obtained by cutting the TD cross-section of the unstretched film by ion milling is described in Figure 5 (a). Figure 5 (b) for identifying Figure 5 Image of a region derived from polyamide A in panel (a).

[0184]

[0185] In Example 1, the types and compounding amounts of polyamide A and polyamide B were changed as shown in Table 2, the extruder was set at 290°C, and the temperature of the mold was set at the temperature shown in Table 1, except Otherwise, it is performed in the same manner.

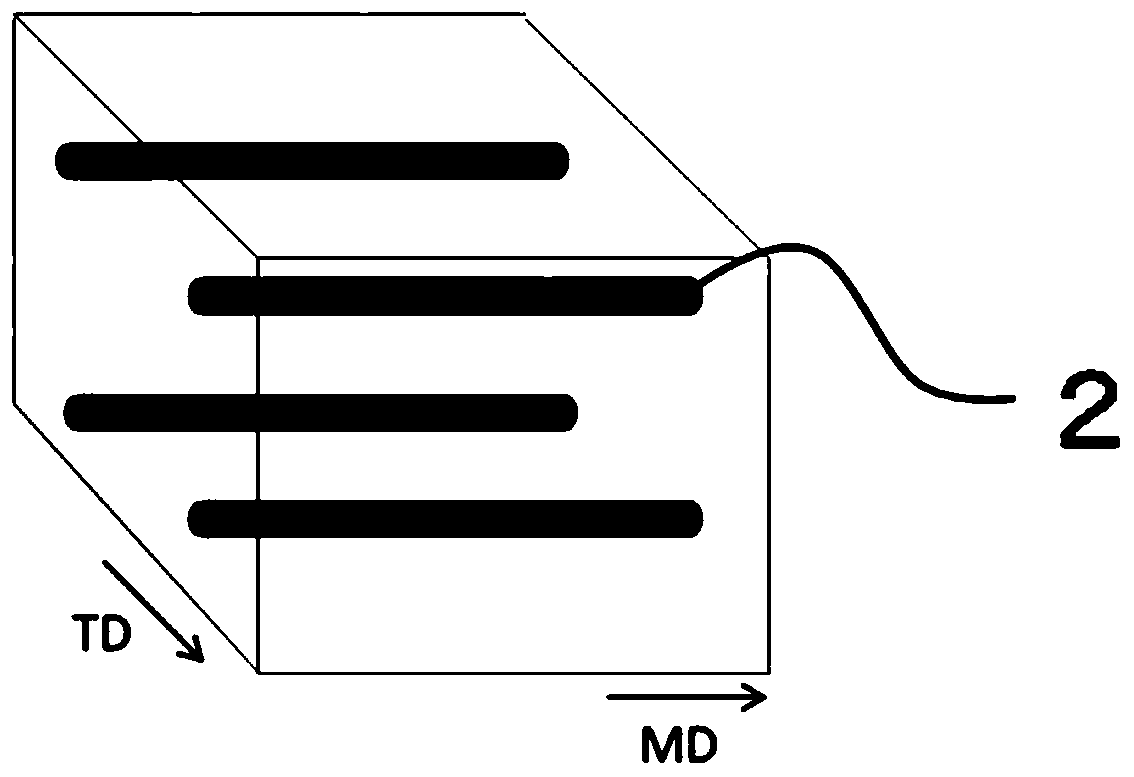

[0186] The sample obtained by cutting the TD cross-section of the unstretched film by ion milling is described in Image 6 (a). Image 6 (b) for identifying Image 6 Image of a region derived from polyamide A in (a).

[0187]

[0188] In Example 1, the types and compounding amounts of polyamide A and polyamide B were changed as shown in Table 2, and the molding method of the easily tearable film was changed as follows, except for the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com