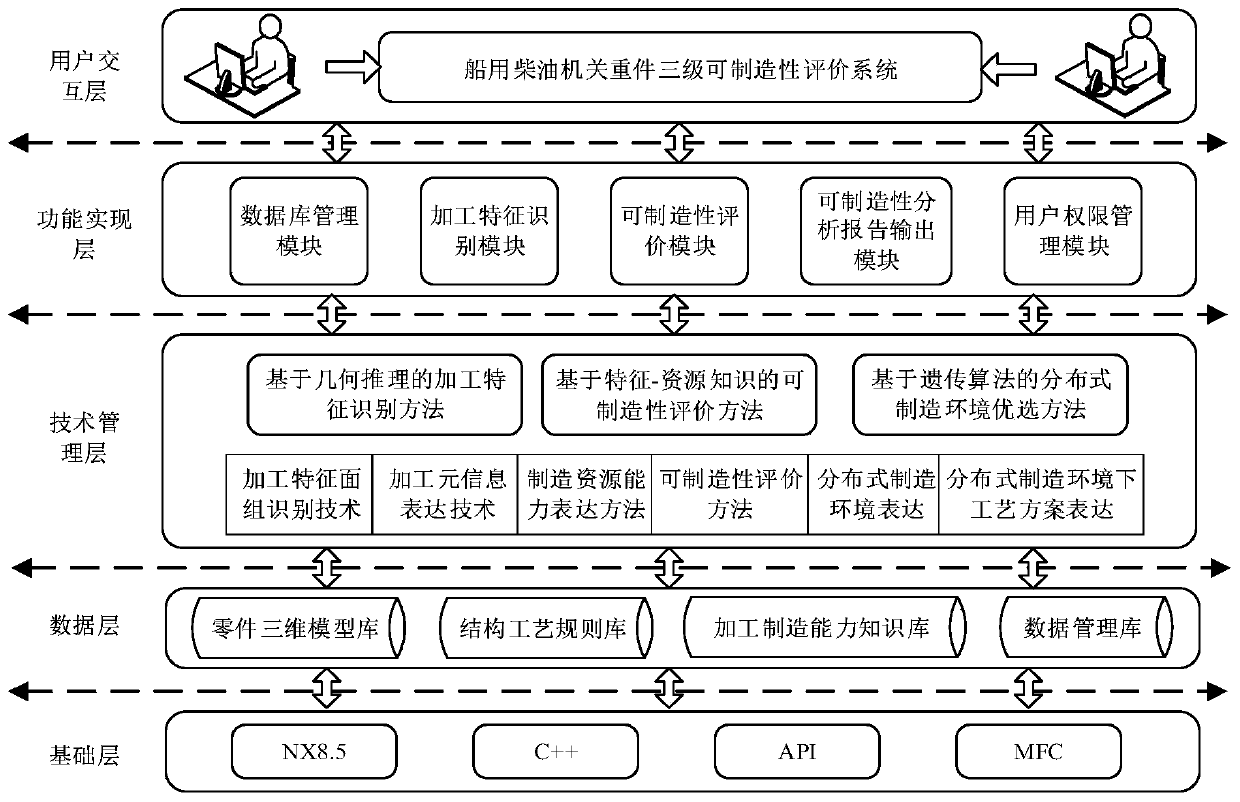

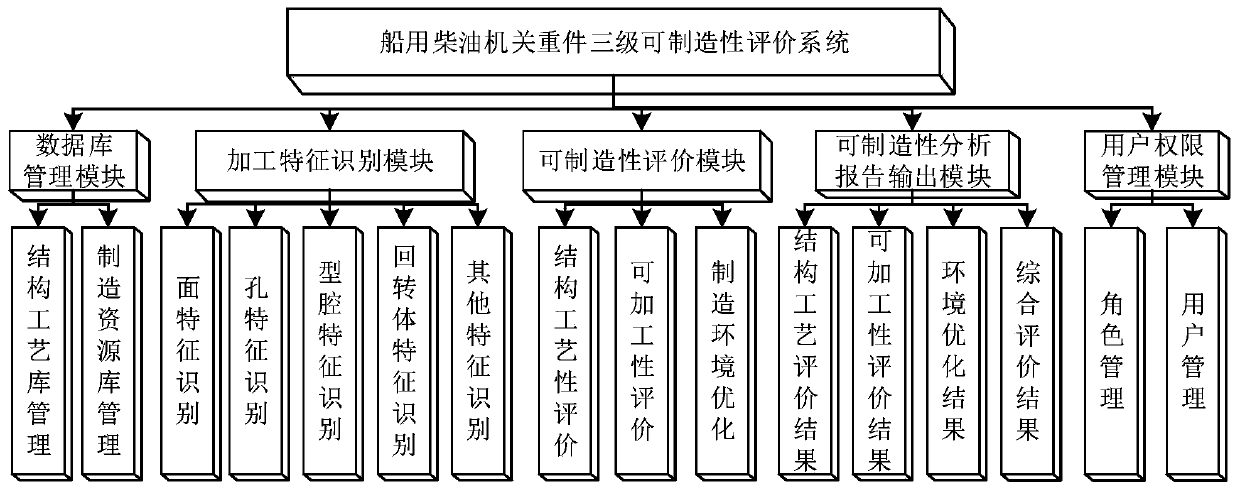

Marine diesel engine heavy part manufacturability three-level optimization method based on feature-resource knowledge

An optimization method and manufacturing technology, applied in design optimization/simulation, genetic models, genetic rules, etc., can solve problems such as design repetition, unreasonable part structure manufacturability, resource conditions, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Example: such as figure 1 As shown, taking connecting rod processing as an example, a manufacturability evaluation system for heavy parts of marine diesel engines based on feature-resource knowledge is implemented in the following steps:

[0056] Step 2, feature recognition, input the 3D CAD model of the connecting rod, combined with the feature classification of critical parts, adopt the interactive recognition algorithm of processing features based on surface and rules, judge and reason the features, and identify the feature types.

[0057] The specific steps of the face and rule-based feature recognition method described in this step are:

[0058] Step1. Use the initial plane as the seed surface to determine the type of the seed surface;

[0059] Step2. Retrieve the outer ring of the seed face, and obtain the adjacent edge of the seed face and its corresponding adjacent face;

[0060] Step3. Obtain the adjacent edge and adjacent surface type;

[0061] Step4. Retri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com