Multifunctional monitoring method for self-adaptive adjustment of wire cut electrical discharge machining process

A technology of self-adaptive adjustment and cutting processing, which is applied in the direction of electric processing equipment, metal processing equipment, and optical method for testing, etc. It can solve problems such as difficult implementation, achieve intuitive monitoring, improve processing efficiency, and improve the surface quality of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

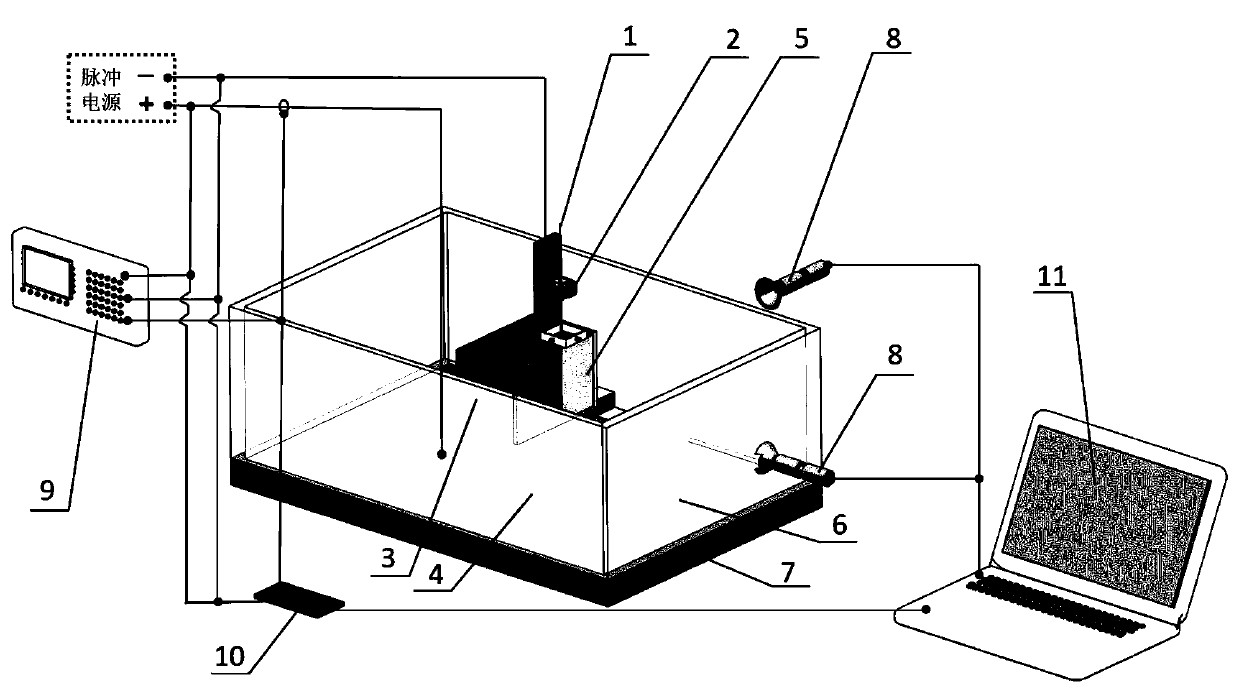

[0034] 1 Construction of the monitoring device

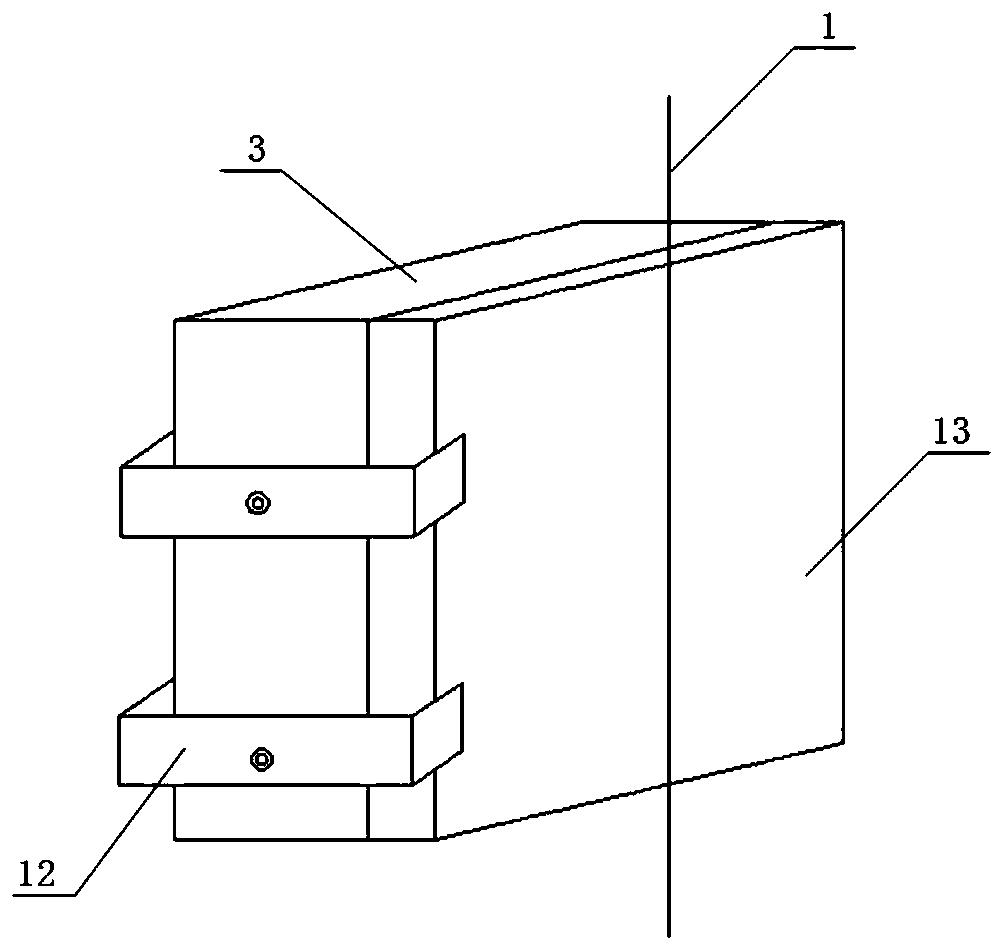

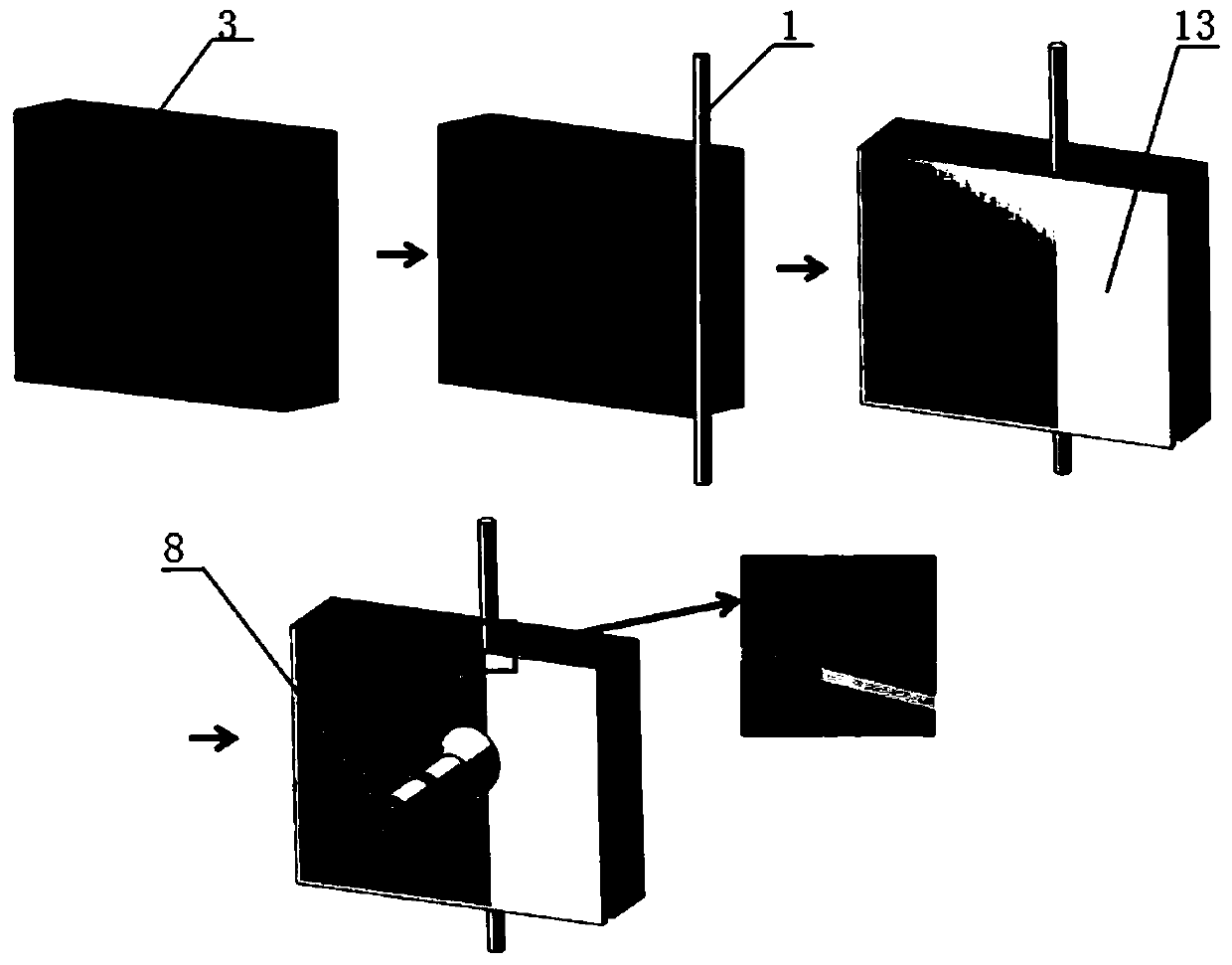

[0035] The monitoring device is set up as figure 1 As shown, there is an operating platform of a wire electric discharge machine tool, the operating platform is composed of a moving platform 4 and a worktable 7, the moving platform 4 is installed on the working platform 7, and then the workpiece 3 to be cut is fixed on the moving platform 4 , and then adjust the wire electric discharge machine tool, so that the wire electrode 1 is tangent to the surface to be cut of the workpiece 3; then a glass baffle 6 is set on the periphery of the edge of the workbench 7 device; a camera of a high-speed camera observation system 8 Place the axis perpendicular to the surface of the workpiece to be cut, and the camera is close to the glass baffle 6; place the camera axis of another high-speed camera observation system 8 parallel to the surface to be cut of the workpiece 3, and align the camera lens with the observation points A and B of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com