Manufacturing method of rock-soil pressure sensor inclusion

A pressure sensor and geotechnical technology, applied in the sensing field, can solve problems such as matching errors, and achieve the effects of reasonable structure, alleviation of incompatibility, and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

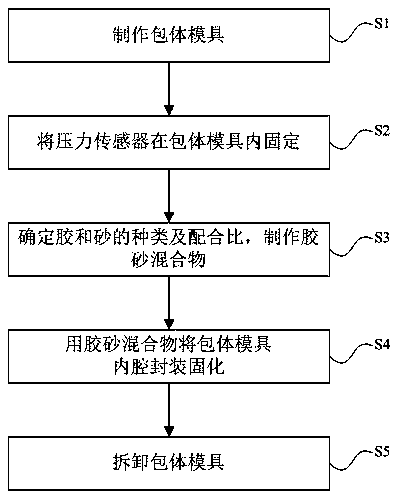

[0026] This embodiment provides a method for making a rock-earth pressure sensor enclosure, such as figure 1 As shown in the process, it includes the following steps:

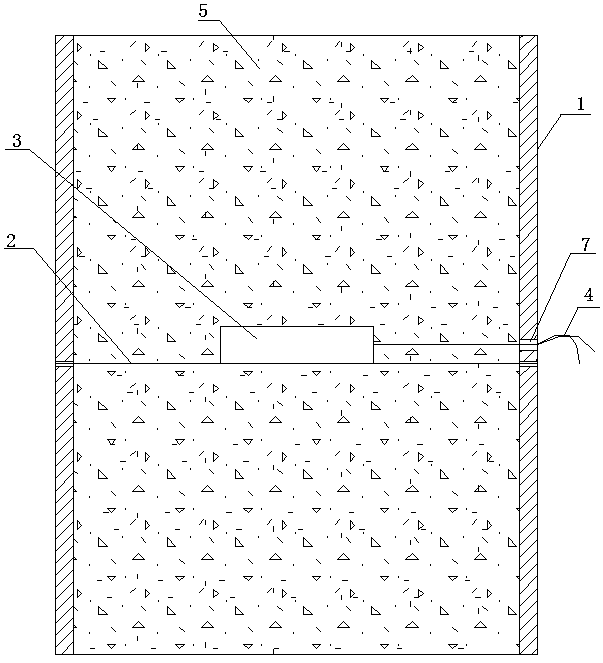

[0027] Step S1, making a rock-earth pressure sensor inclusion mold, such as Figure 2-5 As shown, the encasement mold is composed of a shell 1 and a fixed wire 2, the fixed wire 2 is passed through the middle of the shell 1, the shell 1 is a cylindrical structure with openings at both ends as a whole, and there are Cylindrical cavity, the middle part of the side wall of the cylindrical cavity is provided with four through holes for passing through the fixed line, the axes of the four through holes are located in the same plane A6, and the plane A6 is perpendicular to The housing axis, the height difference between the plane A6 and the axial midpoint of the housing is equal to the sum of the height of the geometric center of the geotechnical sensor 3 and the radius of the fixed line 2, and the side wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com