Carbon fiber composite rivet hole size detection system and method

A carbon fiber material and size detection technology, which is applied in the direction of measuring devices, image data processing, instruments, etc., can solve the problems of difficult to measure the depth information of the inner hole surface and the difficulty of image detection, so as to achieve convenient and intuitive observation, ensure accuracy, and avoid effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is specifically described below through the examples, it is necessary to point out that the present examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the invention, those skilled in the art can according to the above-mentioned present invention Some non-essential improvements and adjustments made in the content of the invention.

[0027] The object of the present invention is achieved by the following technical measures:

[0028] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

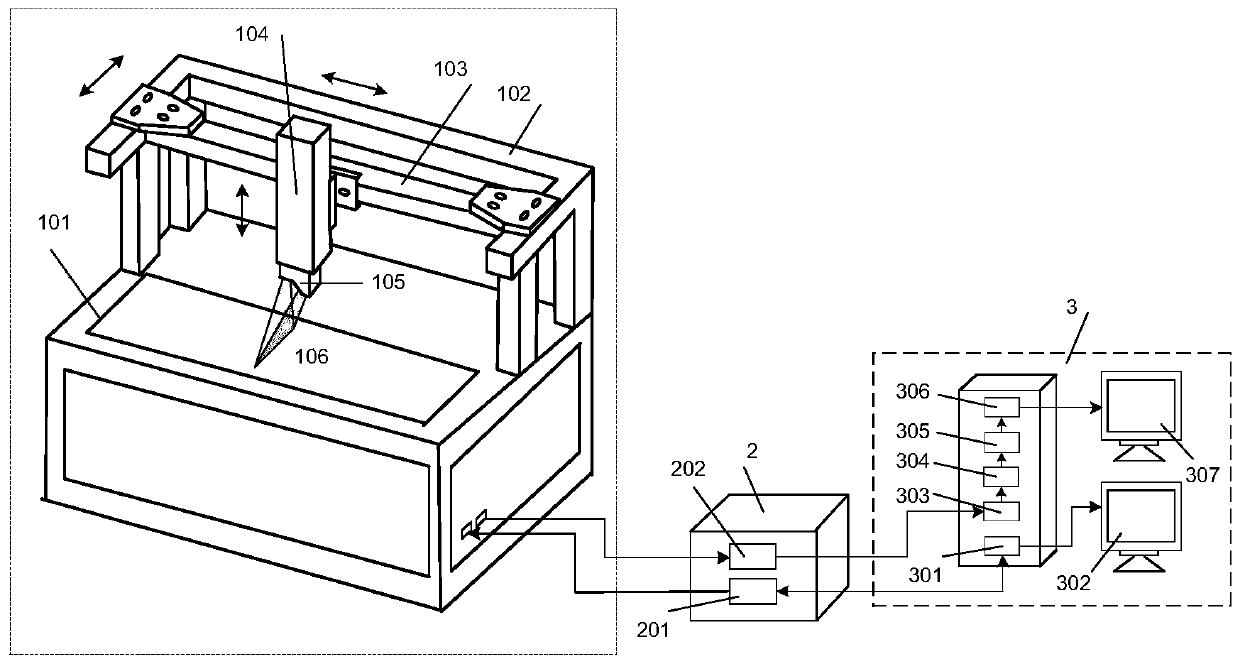

[0029] Such as figure 1As shown, including in the laser detection system 1, the main support 102 is placed on the workbench 101, the beam 103 is installed in front of the main support 102 and can move linearly along the front and rear directions of the main support, and the mechanical arm 104 installed in front of the beam 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com