Explosion center positioning testing device and method

A technology for testing devices and measuring points, which is applied in the direction of measuring devices, optical devices, and ammunition tests. It can solve the problems of easily damaged test cables, high cost, and large test errors, and achieve rapid measurement, low cost, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

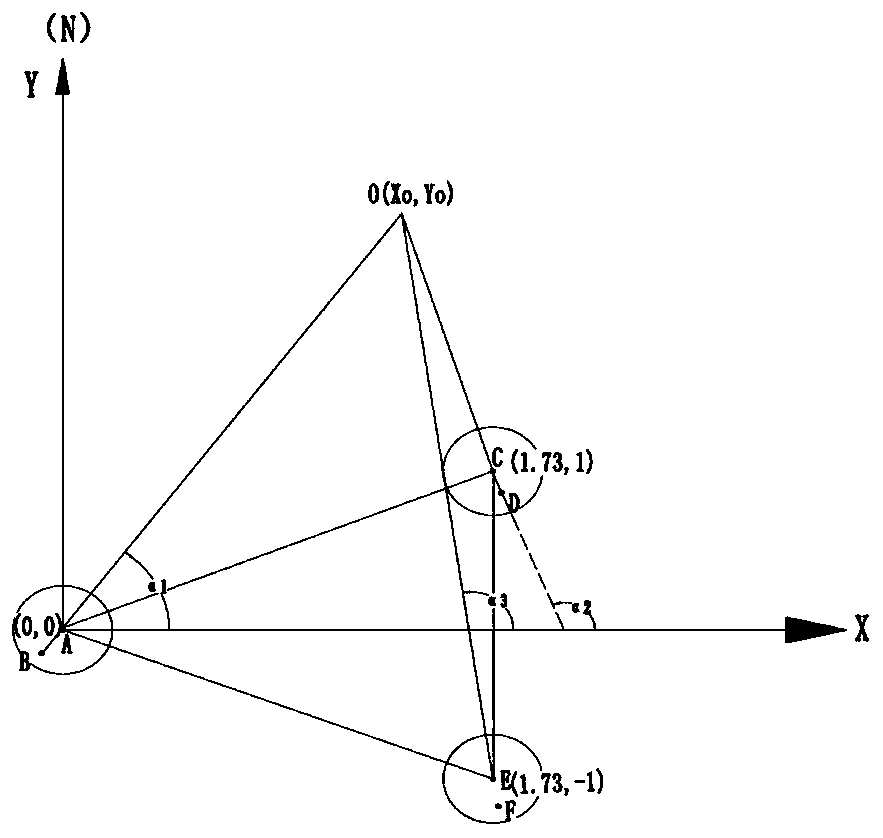

[0048] The TNT explosive with a mass of 1kg is selected for static explosion test, and the explosion center is measured by the method for locating the center of explosion of the present invention.

[0049] Step 1: Establish a rectangular coordinate system on the test site, the X coordinate axis points to the true east, the Y coordinate axis points to the true north, and draws two coordinate axes with white ash;

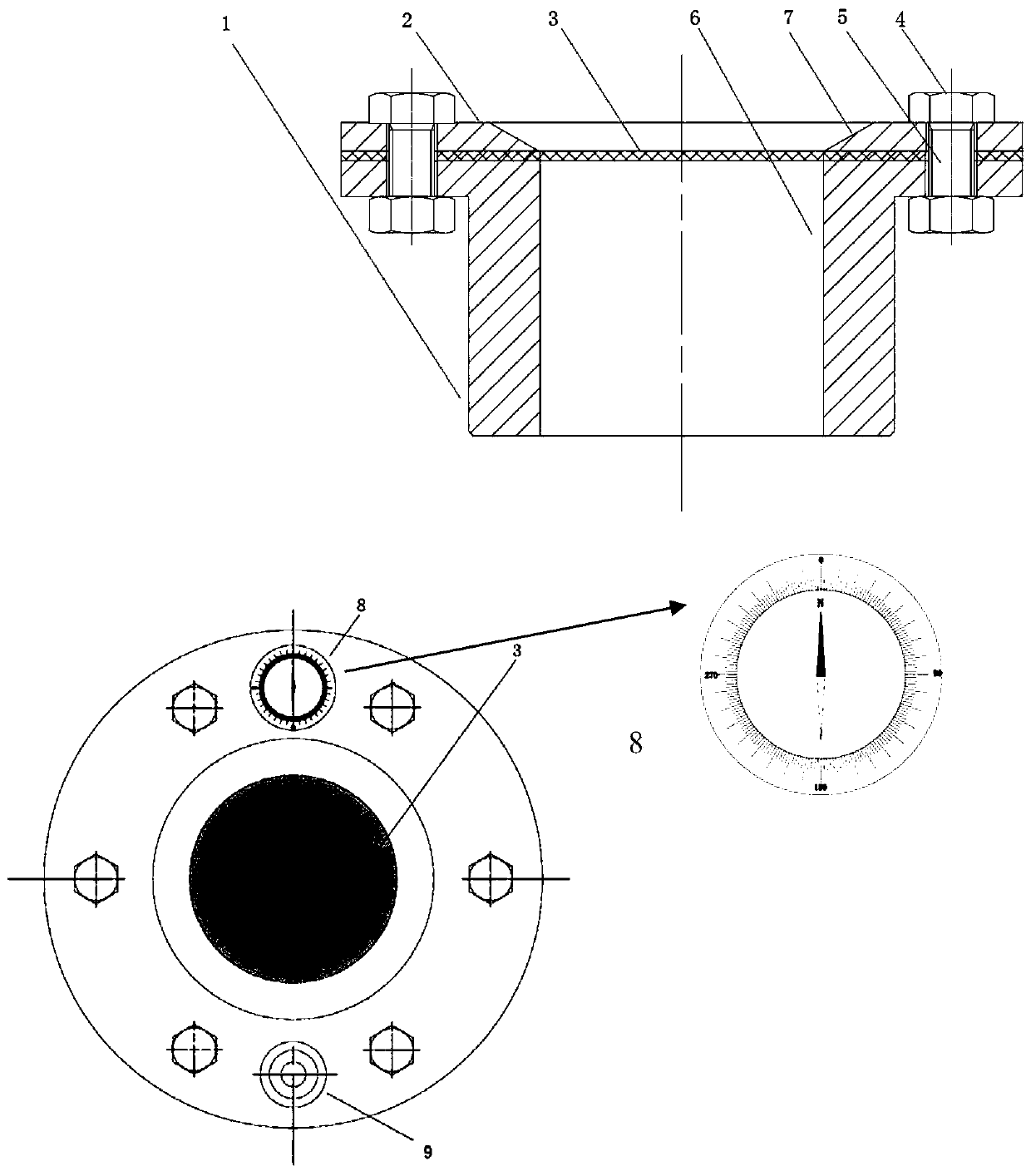

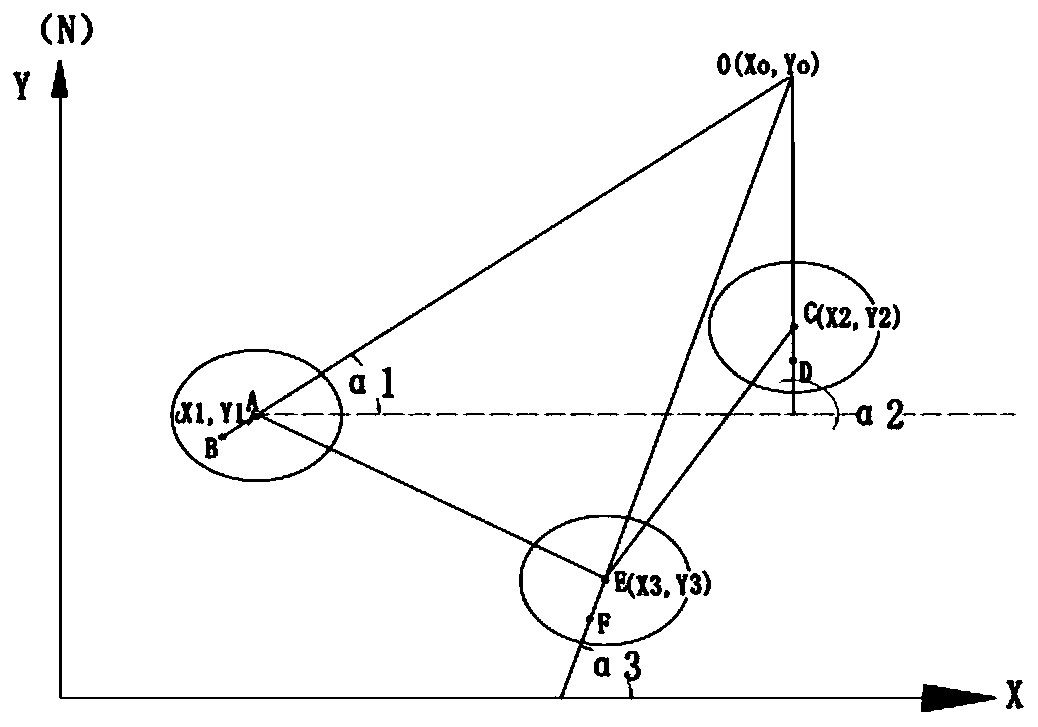

[0050] Step 2: Select 3 points in the virtual coordinate system as the test points. For the convenience of calculation, set the intersection point of the 2 coordinate axes as one of the test points, and install 3 sets of explosion center positioning test devices on the surface to be tested. Use the horizontal bubble to make the upper surface of the test device flush with the ground surface. When installing, ensure that the pressure-sensitive diaphragms of each test point are on the same horizontal plane, and make the compass dial 0° of the test device point to the true...

Embodiment 2

[0069] The TNT explosive with a mass of 1kg is selected for static explosion test, and the explosion center is measured by the method for locating the center of explosion of the present invention.

[0070] Step 1: Establish a rectangular coordinate system on the test site, the X coordinate axis points to the true east, the Y coordinate axis points to the true north, and draws two coordinate axes with white ash;

[0071] Step 2: Install 3 sets of explosion center positioning test devices in the virtual coordinate system at the position to be tested on the ground surface, use horizontal bubbles to make the upper surface of the test device flush with the ground surface, and ensure that the pressure sensitive diaphragms of each test point are on the same horizontal plane during installation , and make the compass dial 0° of the test device point to the true north direction, that is, the positive direction of the Y axis.

[0072] Step 3: Record the relative position of the measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com