A shock wave pressure range measuring device

A pressure range and measuring device technology, applied in the direction of measuring blasting force, etc., can solve the problems of easily damaged test cables, difficult layout, data loss, etc., and achieve the effect of easy installation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

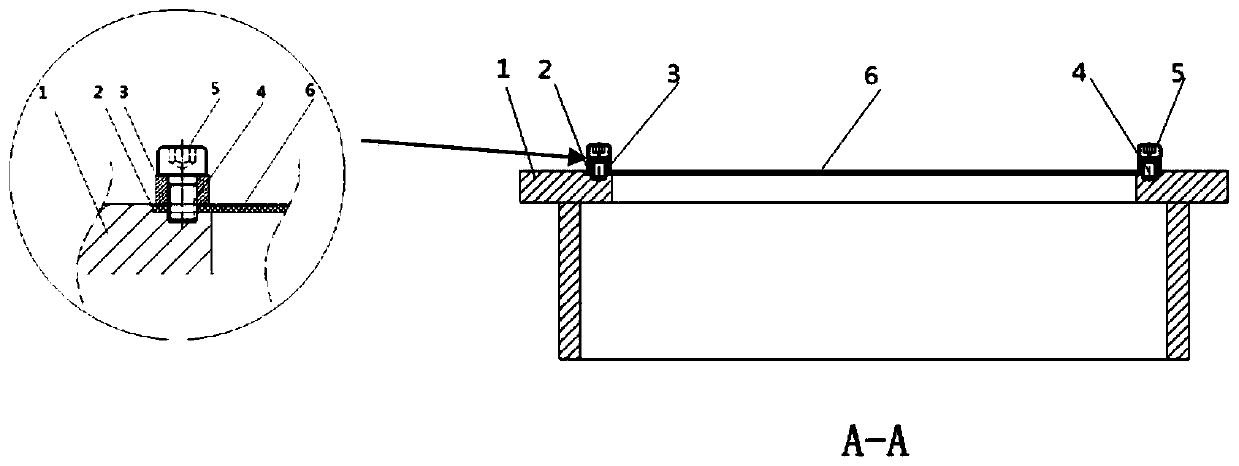

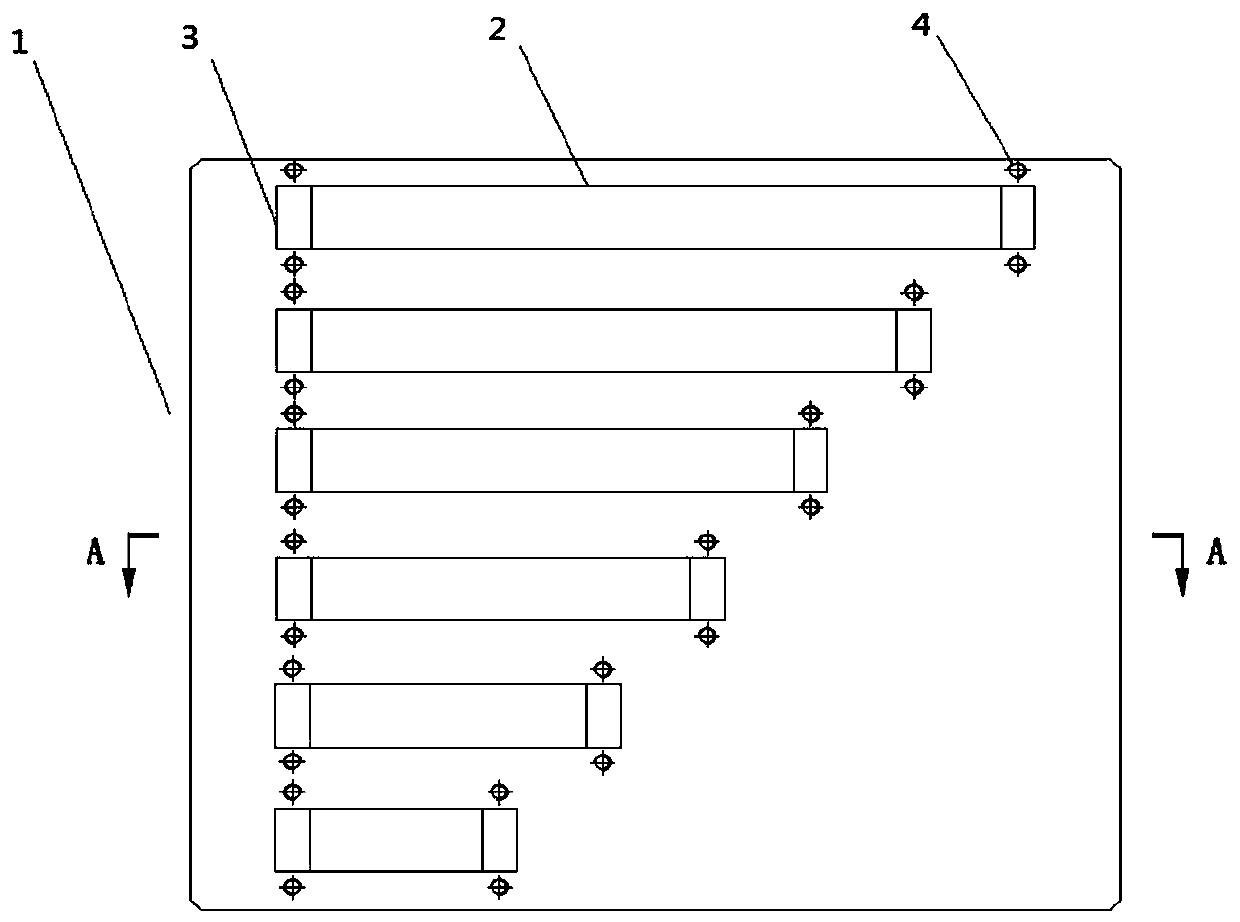

[0017] Comply with above-mentioned technical scheme, preferred embodiment of the present invention is as figure 1 As shown, the size of the installation base 1 is 270mm×270mm×72mm, the thickness of the upper surface is 12mm, and the thickness of the side wall is 8mm; the size of the diaphragm installation groove 2 is 20mm×10mm×0.8mm; the size of the bead 3 is 40mm×10mm ×5mm; bolt mounting hole 4 diameter is Φ5.5mm, compression bolt 5 is M5 screw; acrylic rectangular diaphragm 6 dimensions are 220mm×20mm×1mm; 190mm×20mm×1mm; 160mm×20mm×1mm; 130mm×20mm ×1mm; 100mm×20mm×1mm; 70mm×20mm×1mm.

[0018] Select 2kg spherical TNT explosives for static explosion test, hang the charge on the 1.2m high bomb rack, install the above measuring device at the positions where the projected distance from the charge ground is 2.5m, 3m, 4m, 5m, 6m, and measure the explosion The pressure range of the shock wave at the installation location, and a pressure sensor installed at the same distance for c...

Embodiment 2

[0025] In order to obtain the shock wave pressure range near a certain target in a certain dynamic explosion test, the shock wave pressure range measuring device of the present invention is used, and its overall composition and specific structure are the same as those in Embodiment 1. The ammunition used in the test was filled with TNT explosives, and the charge was 90kg.

[0026] Install the acrylic rectangular diaphragm 6 correspondingly in the diaphragm installation groove 2 of the shock wave range measuring device, then attach the bead 3 to the acrylic rectangular diaphragm 6, and then connect the pressing bolt 5 to the bolt installation hole 4 through the bead 3 installation hole , and compress the acrylic rectangular diaphragm 6 to form the shock wave pressure range measuring device used in this test. The test device of the present invention is arranged at the places where the horizontal distance from the target in the direction of 0°, 90°, 180° and 270° is 8m and 10m re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com