Anti-freezing gas water heater and control method thereof

A technology of a gas water heater and a control method, which is applied in the directions of fluid heaters, lighting and heating equipment, etc., can solve the problems of freezing cracks and water leakage of heat exchangers, difficulty in exhausting smoke, clogging of exhaust pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

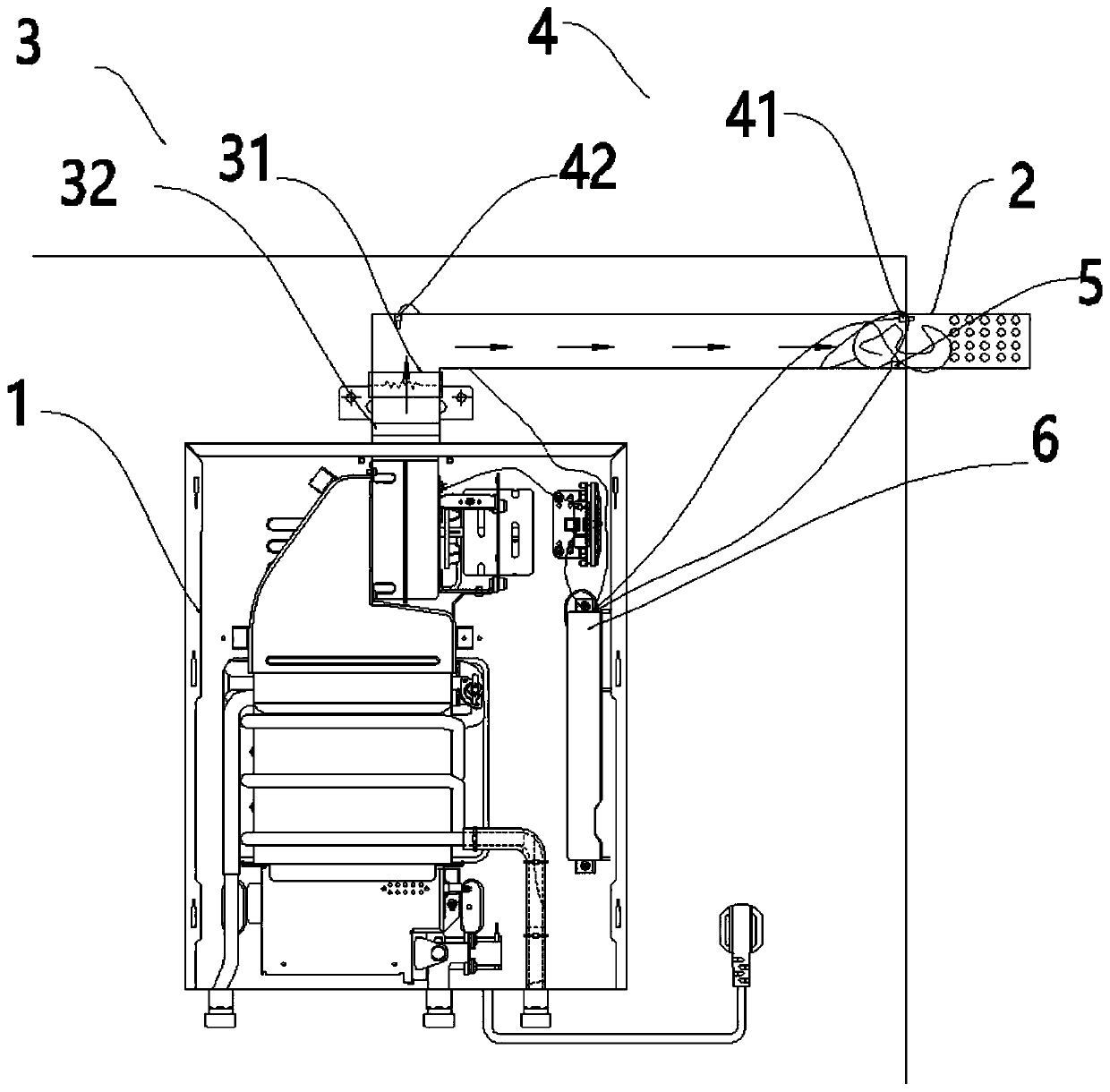

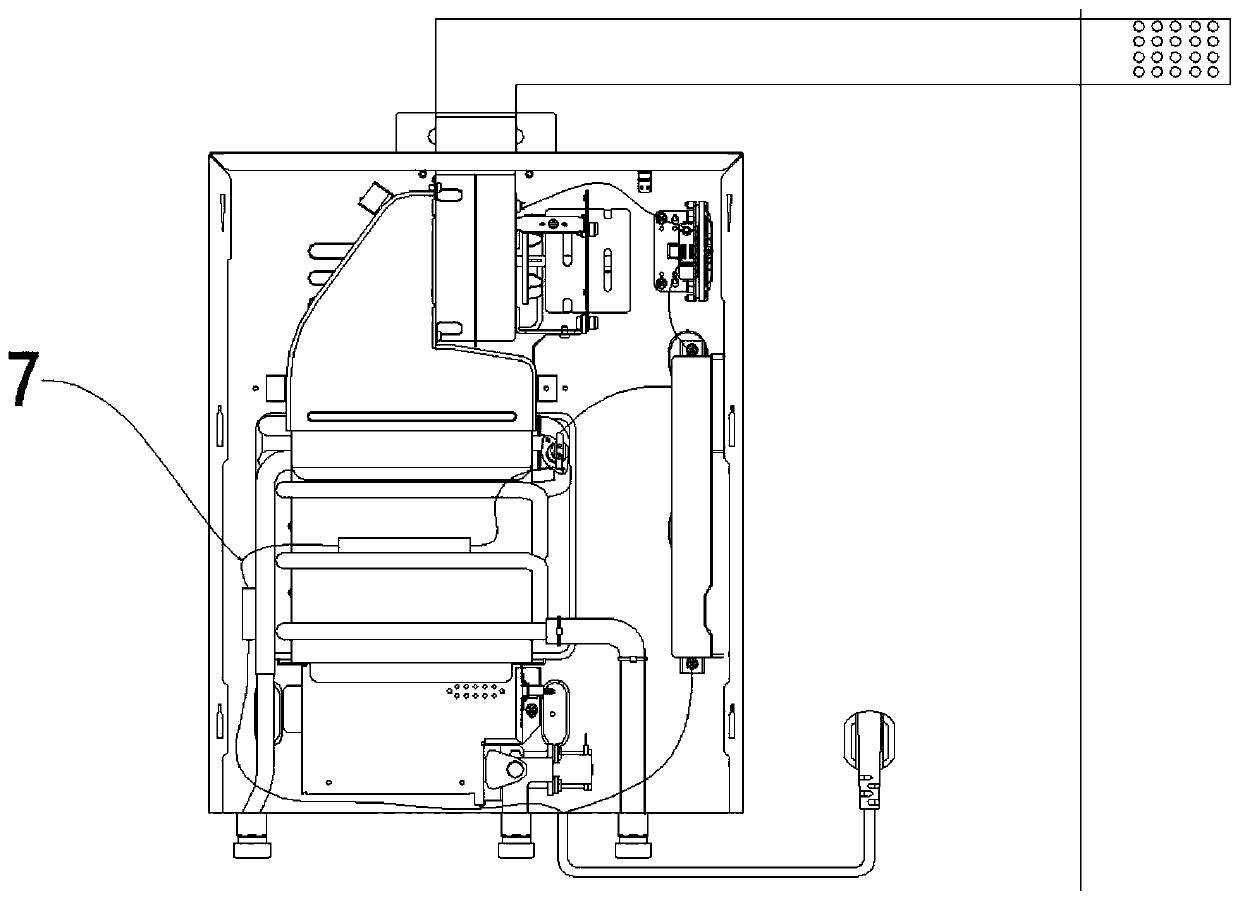

[0032] For this reason, please refer to figure 1 , the present invention provides an antifreeze gas water heater, comprising a gas water heater body 1, a smoke exhaust pipe 2, a heating assembly 3, a temperature sensing element 4, a wind pressure switch 5 and a controller 6; On the inner wall of the smoke pipe 2, and the controller 6 is connected in series, and the temperature sensing element 4 is installed on the smoke exhaust pipe 2 for sensing the temperature, and the sensed temperature is transmitted to the controller 6 through the line, and the sensing The wind pressure switch 5 of the wind pressure is set at the exhaust outlet of the smoke exhaust pipe 2, and the sensed wind pressure is transmitted to the controller 6 through the line, wherein:

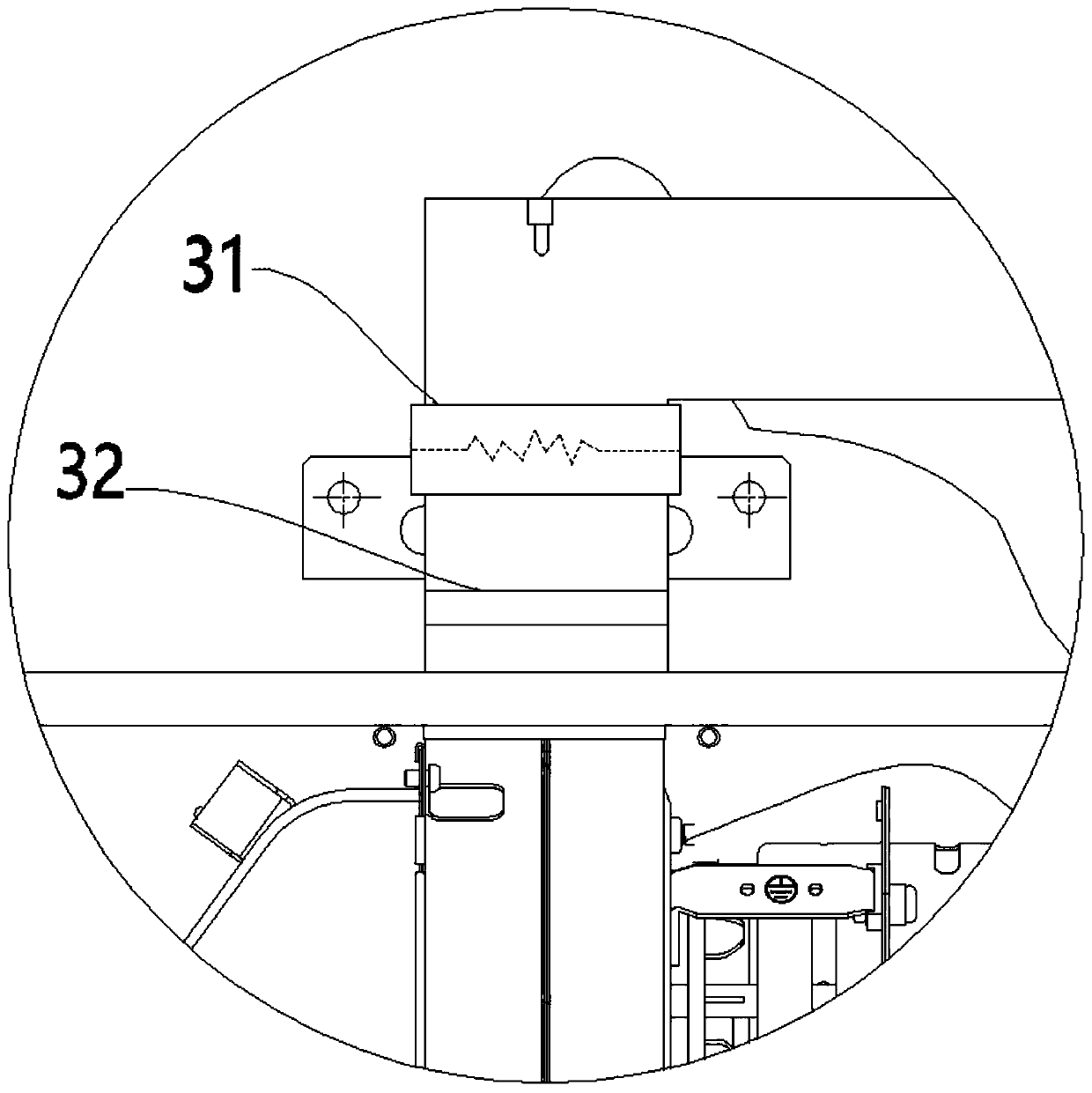

[0033] Such as figure 2 As mentioned above, the heating assembly 3 includes an electric heating tube 31 and a fan 32, the electric heating tube 31 and the fan 32 are sequentially arranged on the inner wall of the exhaust pipe ...

Embodiment 2

[0042] A control method for antifreezing, comprising the steps of:

[0043] Two constant temperature values are set at the controller 6, respectively as the first set value and the second set value, and the first set value will be less than the second set value; and a constant temperature is set at the controller 6 Wind pressure value;

[0044] Obtain the temperature value of the exhaust outlet of the smoke exhaust pipe 2 through the first temperature sensing element 41 as the first detected temperature value; obtain the temperature value of the environment inside the gas water heater through the second temperature sensing element 42, and It is used as the second detected temperature value; the wind pressure signal of the smoke exhaust pipe 5 is obtained through the wind pressure switch 5;

[0045] Transmitting the first detected temperature value and the second detected temperature value and the wind pressure signal to the acquisition module of the controller 6;

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com