VRV air-conditioning system suitable for equipment machine room

A technology for air-conditioning systems and computer rooms, which is applied in air-conditioning systems, mechanical equipment, lighting and heating equipment, etc. It can solve problems such as the inability to adjust the temperature and humidity of the air supply of indoor units, affect the performance of equipment in the computer room, and have no humidification and heating functions. Effects of energy consumption, prevention of short-circuit faults, and prevention of equipment failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

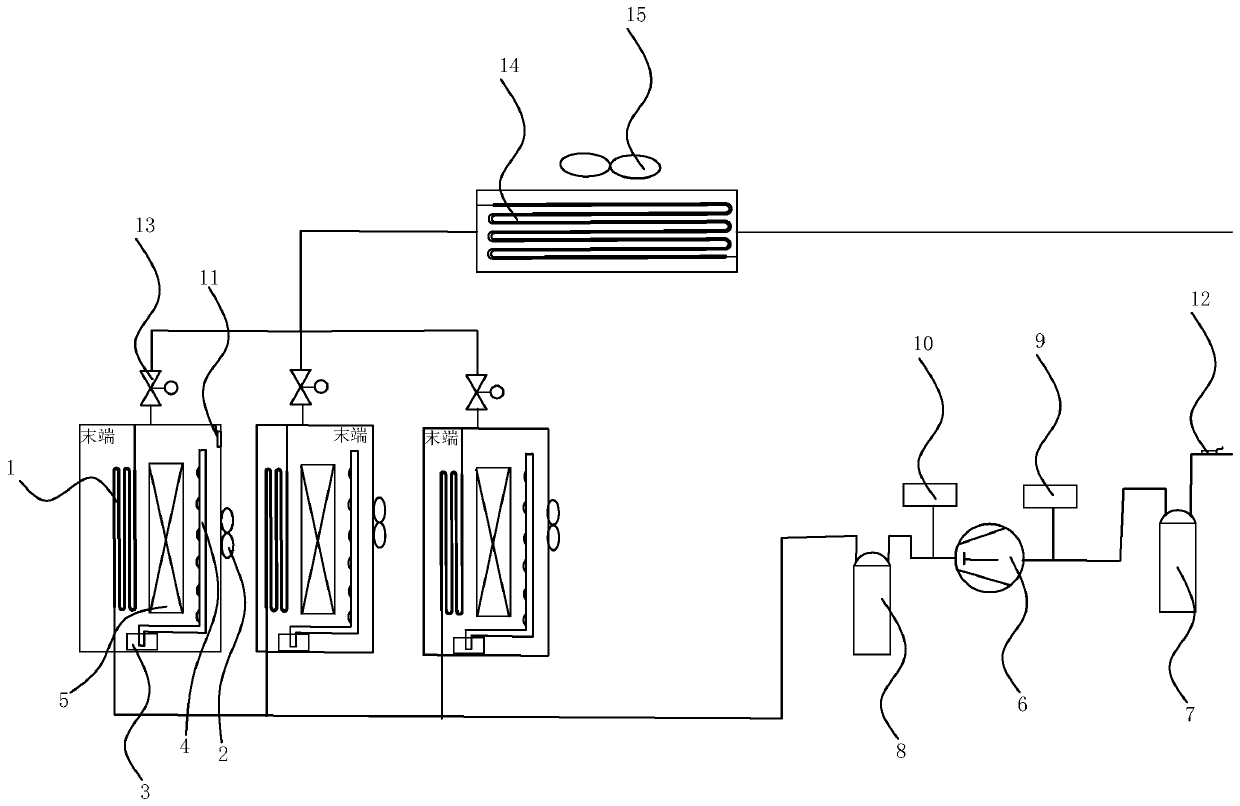

[0034] The above humidification module includes a humidifier 3 and a humidification spray head 4 , and the humidification spray head 4 is connected to the humidifier 3 .

[0035] The implementation principle of this embodiment is: the humidifier 3 is used to generate moisture, and then the moisture is humidified by the air volume provided by the indoor fan 2 through the humidifying nozzle 4 that is softly connected with the humidifier 3, so as to prevent the humidity from being blown by the equipment room. Low wind and humidity lead to excessive static electricity between devices and short-circuit faults.

Embodiment 2

[0037]The above-mentioned heating module includes an electric heater 5 .

[0038] The implementation principle of this embodiment is: use the electric heater 5 to heat the air volume provided by the above-mentioned indoor fan 2, which can avoid the low temperature of the equipment in the equipment room due to the low temperature of the air supply in the equipment room, thereby affecting the performance of the equipment. Further, the above-mentioned electric heater 5 is a PTC heater, which adopts a PTC ceramic heating element and an aluminum tube to form a U-shaped shape. The PTC heater has the advantages of small thermal resistance and high heat exchange efficiency, and the temperature rises rapidly, and when the fan fails Can self-control temperature, long service life.

Embodiment 3

[0040] The cycle refrigeration subsystem includes a variable frequency compressor 6, an oil-gas separator 7, a liquid-gas separator 8, and sensors connected through the pipeline system. The variable frequency compressor 6 is arranged between the oil-gas separator 7 and the liquid-gas separator 8.

[0041] The implementation principle of this embodiment is: the variable frequency compressor 6 can pressurize the circulating refrigerant in the pipeline system, and then separate the oil and water in the refrigerant through the oil-gas separator 7 and the liquid-gas separator 8 to improve The purity of the refrigerant makes the cooling efficiency higher. Furthermore, the variable frequency compressor 6 can adjust its own operating frequency according to the temperature collected by the temperature sensor to adjust the rotation speed of the compressor, control the flow rate of the refrigerant and the flow rate in the pipeline system, so that the terminal indoor unit can be quickly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com