Brake disc liquid cooling circulation method

A cold cycle and brake fluid technology, applied in the field of brake disc cooling, can solve problems such as waste of water resources, affecting driving safety, etc., and achieve excellent cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

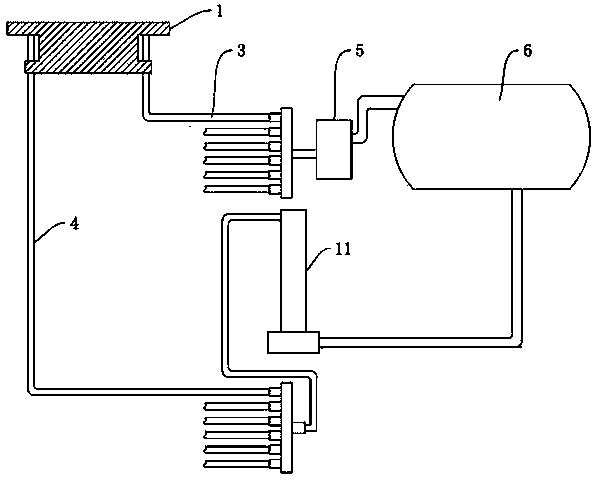

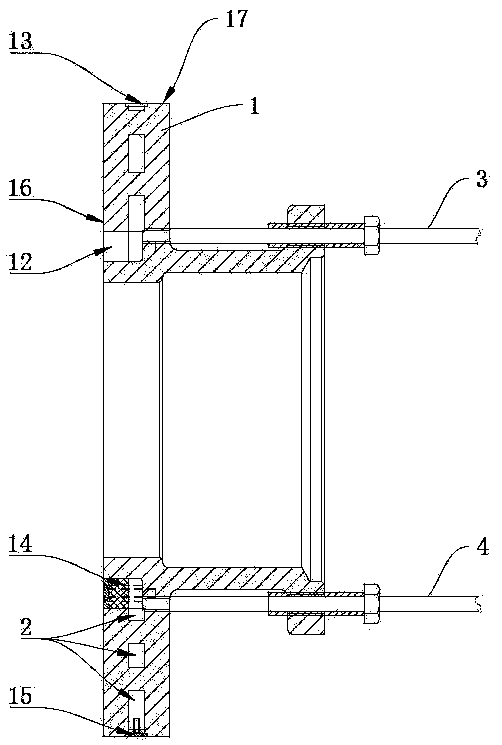

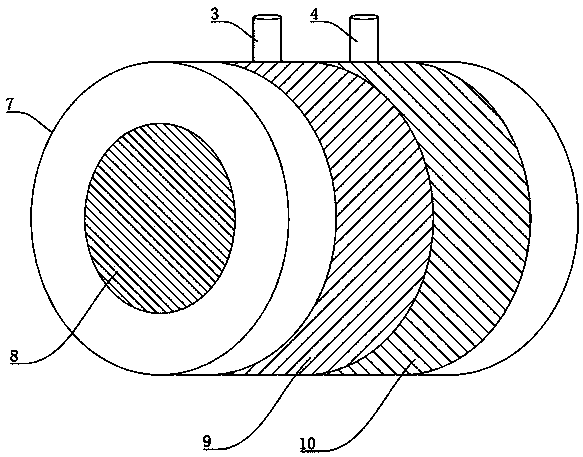

[0022] Figure 1-3 A preferred embodiment of the brake disc liquid cooling circulation method of the present invention is shown. The brake disc liquid cooling circulation method in this embodiment includes the following steps: S1, the air cooling port of the disc brake disc 1 with the cooling cavity 2 is cooled. Blocking to form a sealed cavity, and set the water inlet pipe 3 and the water outlet pipe 4 connected with the cooling chamber 2 on the disc brake disc 1; S2, use the water pump 5 to extract the circulating water in the water tank 6 of the vehicle, and make the circulating water flow from the inlet The water pipe 3 flows into the cooling chamber 2 ; S3 , the circulating water in the cooling chamber 2 after cooling the disc brake disc 1 flows out from the water outlet pipe 4 and returns to the water tank 6 .

[0023] Block the air cooling port of the original cooling cavity 2 in the disc brake disc 1, and then make the cooling cavity 2 in a closed state, set the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com