Polypropylene composite material with obvious pearlescent effect, and preparation method and application thereof

A composite material, pearlescent effect technology, applied in the field of polypropylene modification, to achieve the effect of improving rigidity and hardness, improving scratch resistance, and obvious pearlescent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

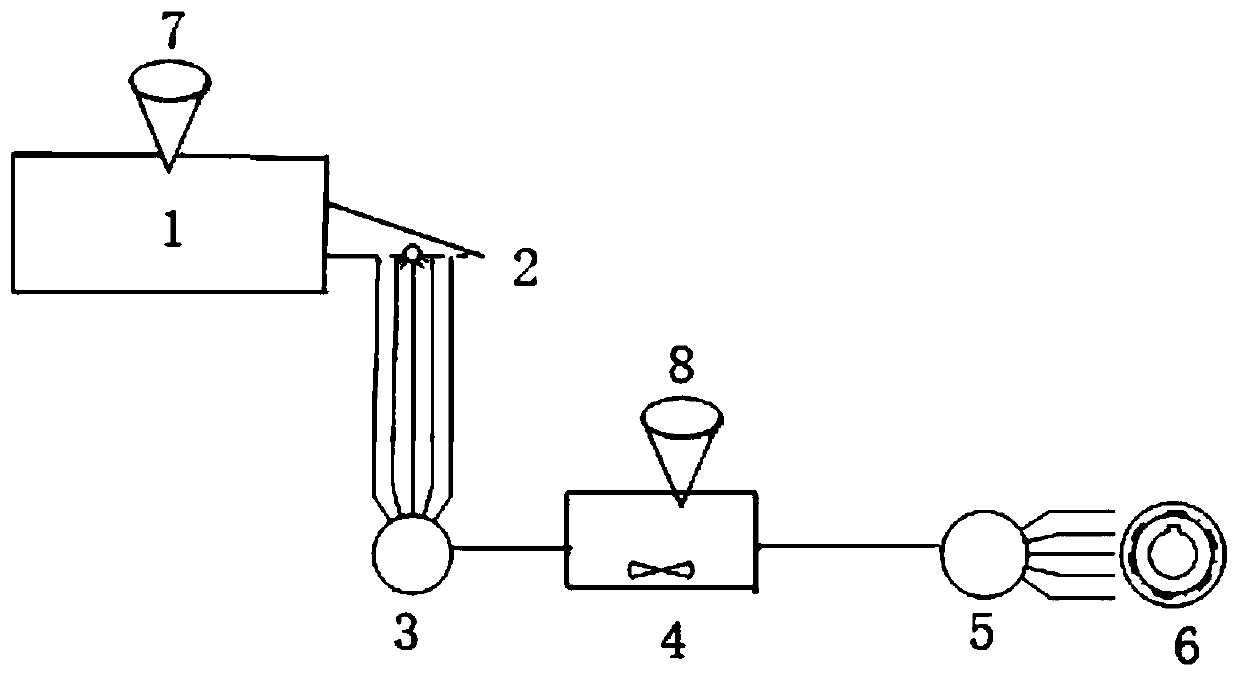

Method used

Image

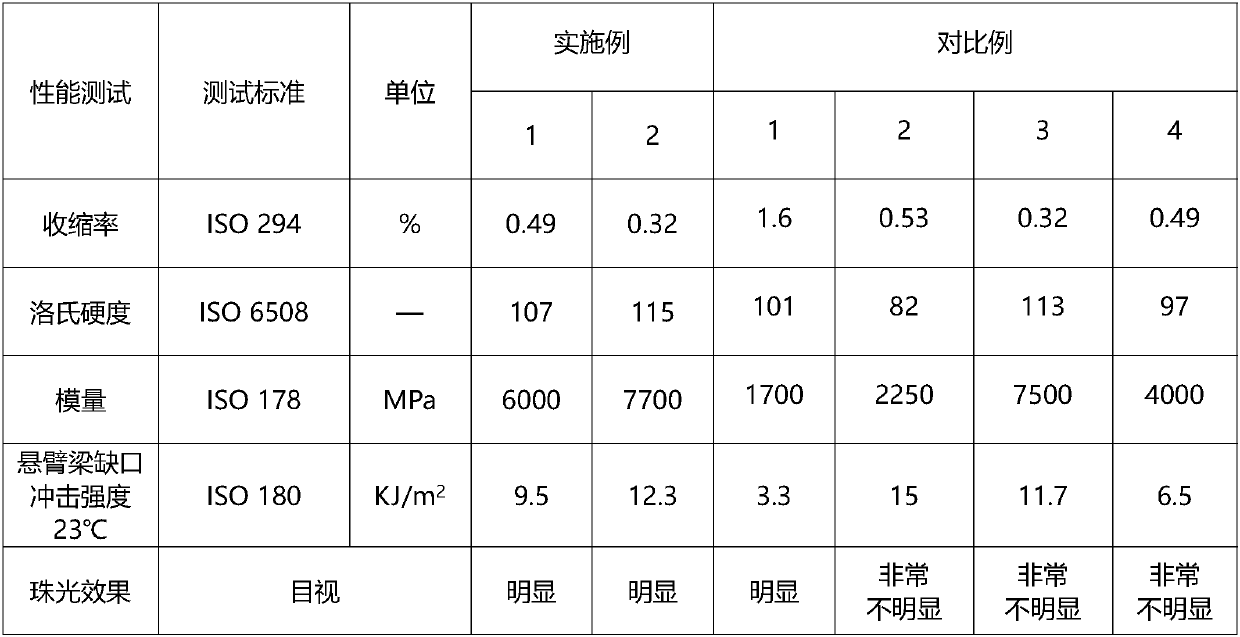

Examples

Embodiment 1

[0041] (1) Preparation of glass fiber-based pearlescent pigments: put 100kg of chopped glass fibers into the first high-temperature furnace at 1250°C for melting, set a 14um aperture spinneret tray at the bottom of the melting furnace, open the spinneret tray, and melt the glass The fiber filaments are sprayed out and passed through the second high-temperature melting furnace at 650°C under the traction of the wire rack in the horizontal direction. A stirring paddle is set at the bottom of the high-temperature furnace, and 2.3kg of titanium dioxide and 0.25kg of pure zinc are melted and dispersed, and the titanium dioxide and metallic zinc are uniform It is dip-coated on the smooth glass fiber surface, and cut into 3-5mm fiber segments by a shredder under the traction of the wire separator, and finally obtains a glass fiber-based pearlescent pigment with a coating rate of 70%.

[0042] (2) Preparation of polypropylene composite material: Weigh 7.2kg of high stiffness copolymer ...

Embodiment 2

[0044] (1) Preparation of glass fiber-based pearlescent pigments: put 100kg of chopped glass fibers into the first high-temperature furnace at 1250°C for melting, set a 14um aperture spinneret tray at the bottom of the melting furnace, open the spinneret tray, and melt the glass The fiber filaments are sprayed out and passed through the second high-temperature melting furnace at 700°C under the traction of the wire rack in the horizontal direction. Stirring paddles are installed at the bottom of the high-temperature furnace to melt and disperse 3.3kg of titanium dioxide and 1.7kg of pure zinc, and the titanium dioxide and metal zinc are uniform It is dip-coated on the smooth glass fiber surface, and cut into 3-5mm fiber segments by a shredder under the traction of the wire separator, and finally obtains a glass fiber-based pearlescent pigment with a coating rate of 85%.

[0045] (2) Preparation of polypropylene composite material: Weigh 7.0kg homopolypropylene PPH-PP6012, 0.45k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com