A kind of polyether modified organosilicon with crosslinking structure and preparation method thereof

A technology of polyether modification and cross-linking structure, which is applied in the field of cross-linking structure polyether modified silicone and its preparation, which can solve the complex preparation process of organo-modified polysiloxane, unfavorable large-scale industrial production, environmental pollution, etc. problems, to achieve the effect of flexible and convenient preparation method, convenient preparation and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

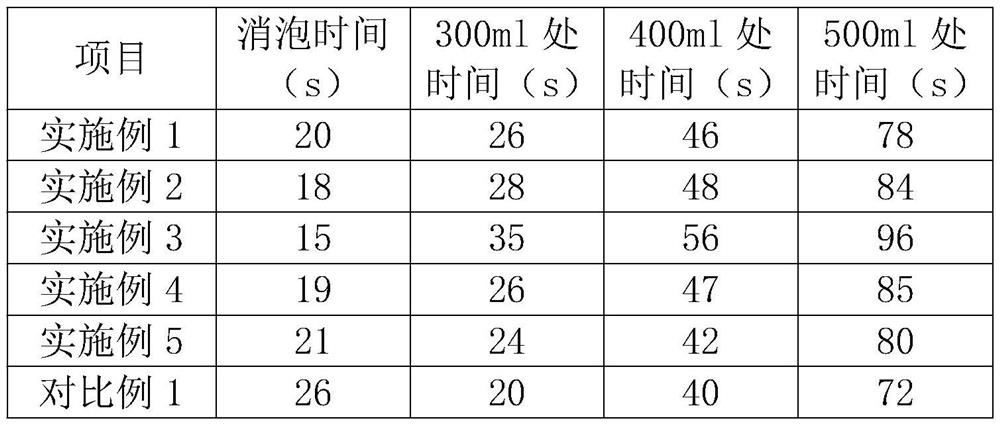

Examples

Embodiment 1

[0019] Example 1. A method for preparing a polyether-modified organosilicon with a cross-linked structure. The polyhydroxysilanol-containing prepolymer obtained by hydrolysis of methyltriethoxy under the action of a catalyst (hydrochloric acid): 90g, propylene glycol polyoxypropylene Ether PPG100O (molecular weight 1000): 80g; viscosity is 80000mPa. s 107 glue: 25g; put it into a 500ml four-neck flask, stir and heat up to 80 degrees Celsius, put in 0.1g of dibutyltin dilaurate as a catalyst, continue to reduce pressure and heat up and stir to 145 degrees Celsius, until the material gradually changes from turbid to colorless and transparent, And when there is no new water to produce in the negative pressure collection bottle, the temperature will be lowered.

Embodiment 2

[0020] Example 2. A method for preparing a polyether-modified organosilicon with a crosslinked structure. The polyhydroxysilanol-containing prepolymer obtained by hydrolysis of methyltriethoxy under the action of a catalyst (hydrochloric acid): 90g, propylene glycol polyoxypropylene Ether PPG100O (molecular weight 1000): 40g; GPE-3000 (glycerol polyoxypropylene polyoxyethylene ether): 40g; viscosity 20000mPa. s 107 glue: 25g; put it into a 500ml four-neck flask, stir and heat up to 80 degrees Celsius, put in 0.1g of dibutyltin dilaurate as a catalyst, continue to reduce pressure and heat up and stir to 145 degrees Celsius, until the material gradually changes from turbid to colorless and transparent, And when there is no new water to produce in the negative pressure collection bottle, the temperature will be lowered.

Embodiment 3

[0021] Example 3. A method for preparing a polyether-modified organosilicon with a crosslinked structure. The polyhydroxysilanol-containing prepolymer obtained by hydrolysis of methyltriethoxy under the action of a catalyst (hydrochloric acid): 90g, propylene glycol polyoxypropylene Ether PPG200O (molecular weight 2000): 10g; GPE-3000 (glycerin polyoxypropylene polyoxyethylene ether): 40g; viscosity is 80000mPa. s 107 glue: 25g; put it into a 500ml four-necked flask, stir and heat up to 80 degrees Celsius, put in 0.05g of dibutyltin dilaurate and 0.05g of butyl titanate as catalysts, continue to depressurize and heat up to 145 degrees Celsius, until the material turns from turbid When it gradually becomes colorless and transparent, and no new water is produced in the negative pressure collection bottle, it can be obtained by cooling down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com