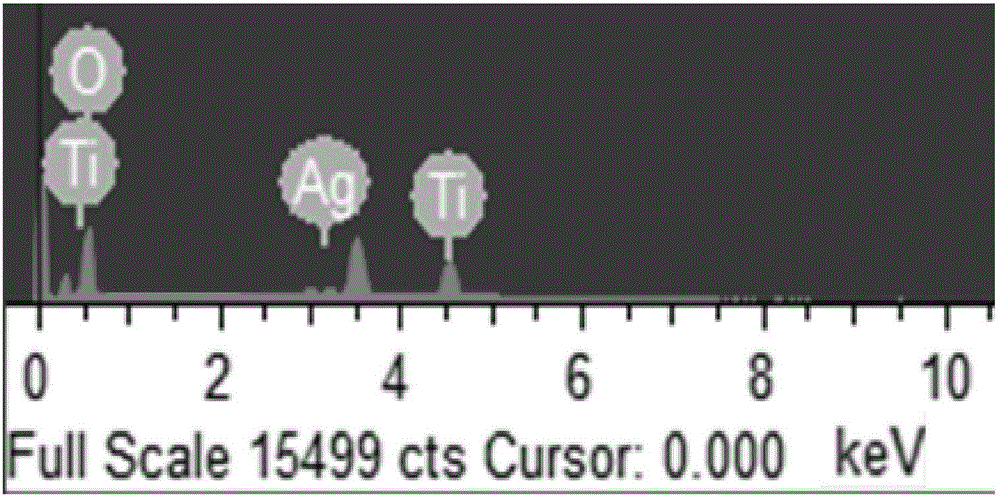

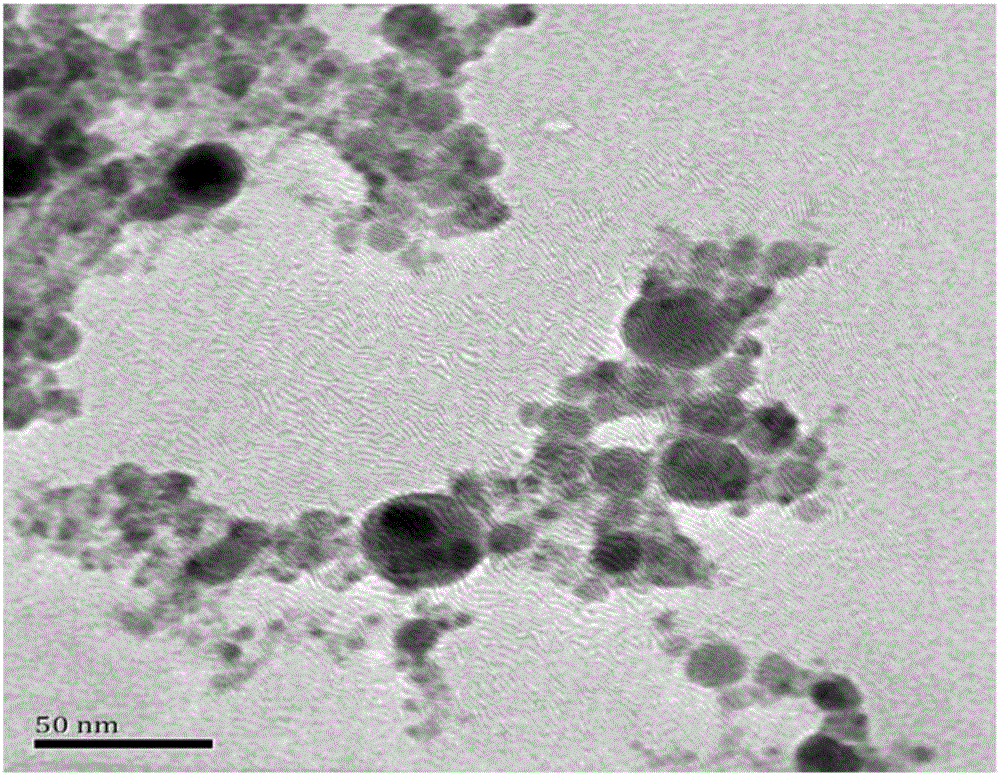

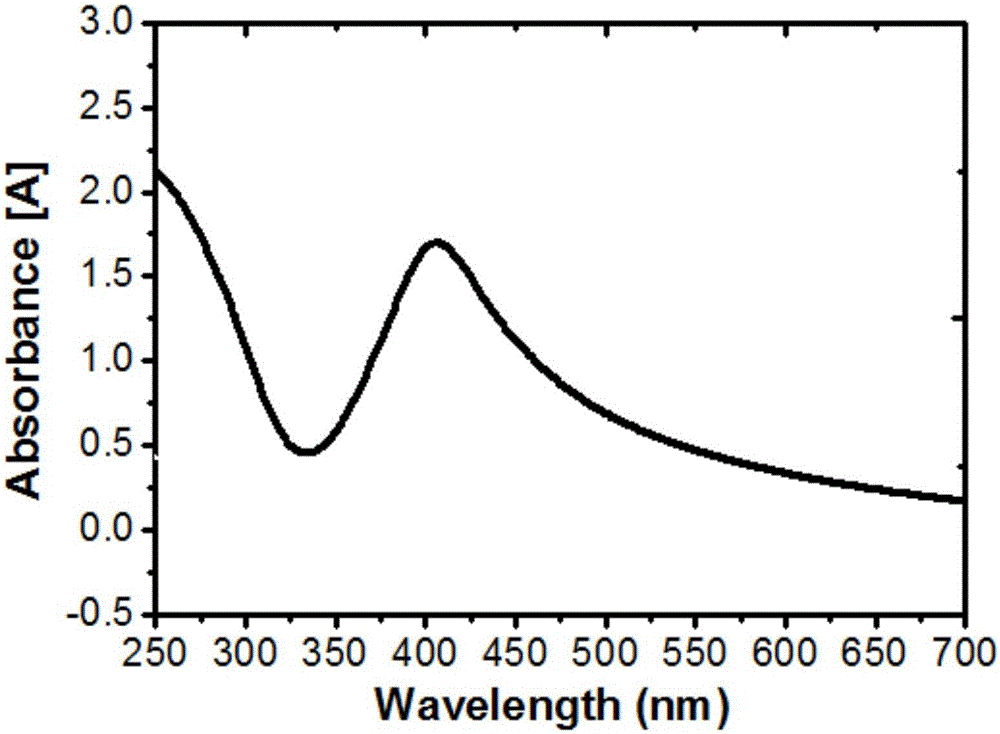

Preparation method of silver-carrying titanium dioxide nanocomposite photocatalyst

A silver-loaded titanium dioxide, nano-composite technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the complex preparation process, poor stability, and the need for chemical additives. and other problems, to achieve the effects of improving performance, improving utilization, and flexible and convenient preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of silver-loaded titanium dioxide nanocomposite photocatalyst, comprising the steps of:

[0027] (1) Ultrasonic cleaning of the titanium sheet and silver sheet in deionized water for 25-35 minutes, and then ultrasonic cleaning in absolute ethanol for 25-35 minutes; the purity of the above-mentioned titanium sheet is 99.99%, and the size is 20mm×20mm×2mm, The purity of the above-mentioned silver flakes is 99.8%, and the size is Φ15mm×2mm;

[0028] (2) Put the titanium sheet cleaned in step (1) into 3.5mL deionized water, ablate the surface of the titanium sheet with a fiber optic pulse laser, take out the remaining titanium sheet, and prepare a titanium dioxide nanoparticle solution, wherein the titanium sheet and the liquid The surface distance is 1.8~2.2mm;

[0029] (3) Put the silver flakes cleaned in step (1) into the titanium dioxide nanoparticle solution obtained in step (2), ablate the surface of the silver flakes with an optical fiber pulse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com