Smokeless sulfur-free firework stabilizing agent and preparation method thereof

A technology of stabilizer and sulfur fireworks, used in non-explosive stabilizers, offensive equipment, non-explosive/non-thermal components, etc., can solve problems such as pollution of the environment, and achieve the effects of no three-waste discharge, simple process, and few steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

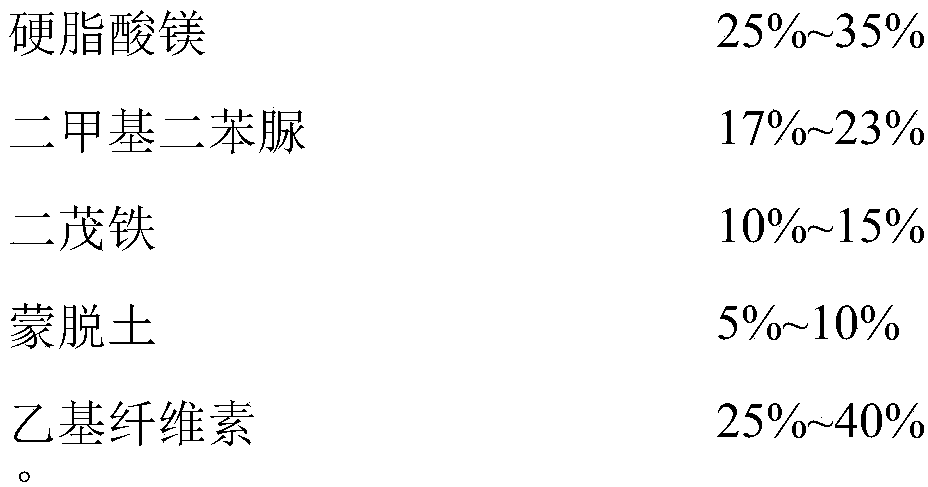

[0024] A smokeless and sulfur-free fireworks stabilizer, the mass percentages of its components are as follows:

[0025]

[0026] Add 25g of magnesium stearate and 17g of dimethyldiphenylurea into 80g of ethanol respectively under stirring, after heating to 60°C, stir continuously until the solute is completely dissolved to obtain solution A; under stirring, add 12g of ferrocene Add it into 25g of dichloromethane (20%) / petroleum ether mixed solvent, and stir continuously until the ferrocene is completely dissolved to obtain solution B; under stirring, add solution A to solution B, heat up to 75°C, and Add 10g of montmorillonite and 36g of ethyl cellulose in sequence under stirring, and continue to stir at a rate of 70rpm until the material becomes a uniform micelle; After vacuum drying at 60°C for 12 hours, the crude smokeless and sulfur-free fireworks stabilizer was obtained; the crude smokeless and sulfur-free fireworks stabilizer was lightly crushed, passed through a 300...

Embodiment 2

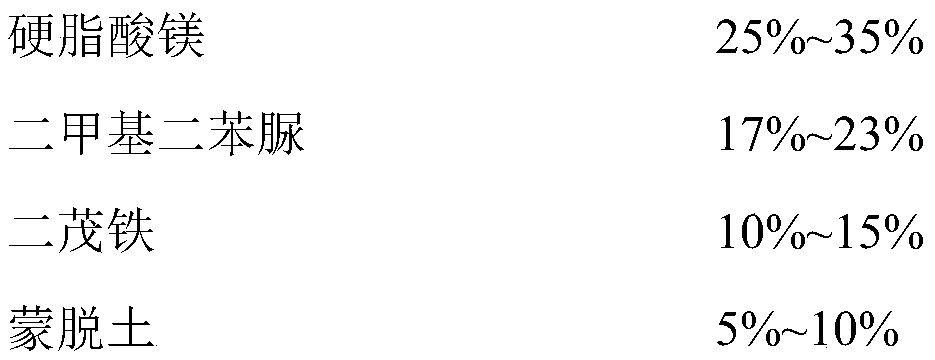

[0028] A smokeless and sulfur-free fireworks stabilizer, the mass percentages of its components are as follows:

[0029]

[0030] Add 300g of magnesium stearate and 200g of dimethyldiphenylurea into 1200g of ethanol respectively under stirring, after heating to 65°C, stir continuously until the solute is completely dissolved to obtain solution A; under stirring, add 100g of ferrocene Add it to 300g of dichloromethane (30%) / petroleum ether mixed solvent, and continue to stir until the ferrocene is completely dissolved to obtain solution B; while stirring, add solution A to solution B, and heat up to 83°C. Add 50g of montmorillonite and 350g of ethyl cellulose sequentially under stirring, and continue to stir at a rate of 80rpm until the material becomes a uniform micelle; Granulate and vacuum dry at 60°C for 12 hours to obtain the crude smokeless and sulfur-free fireworks stabilizer; lightly crush the obtained smokeless and sulfur-free fireworks stabilizer, pass through a 30...

Embodiment 3

[0032] A smokeless and sulfur-free fireworks stabilizer, the mass percentages of its components are as follows:

[0033]

[0034] Add 3.5kg of magnesium stearate and 2.2kg of dimethyl diphenyl urea into 15kg of ethanol respectively under stirring, after heating to 70°C, stir continuously until the solute is completely dissolved to obtain solution A; Add ferrocene to 3.5kg of dichloromethane (40%) / petroleum ether mixed solvent, and stir continuously until the ferrocene is completely dissolved to obtain solution B; while stirring, add solution A to solution B, and heat up to 90°C Finally, add 0.5kg montmorillonite and 2.8kg ethyl cellulose successively under stirring state, continue to stir with 100rpm speed until the material becomes uniform micelles; Granulate with a granulator, vacuum dry at 60°C for 12 hours to obtain the crude smokeless and sulfur-free fireworks stabilizer; lightly crush the crude smokeless and sulfur-free fireworks stabilizer, and pass through a 300-mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com