Low-cost heat-resistant magnesium cement and method for preparing building block from same

A magnesium cement, low-cost technology, applied in the field of low-cost heat-resistant magnesium cement and its preparation blocks, can solve the problems of not mentioning the highest service temperature and high-temperature durability, unable to judge the performance, and the floor is not refractory, so as to improve the performance. Fire safety grade, good fire resistance, and the effect of preventing skin peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

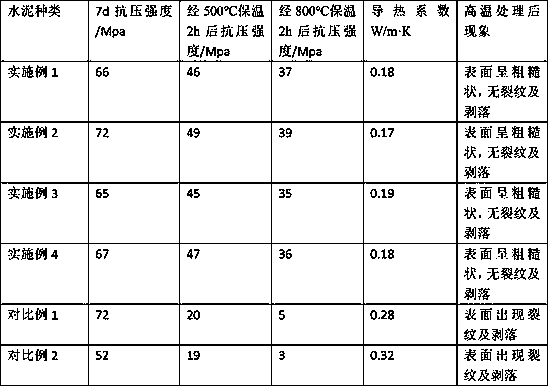

Examples

Embodiment 1

[0030] A low-cost heat-resistant magnesium cement comprises the following components by weight: 60 parts of light-burned magnesium oxide powder, 26 parts of silica fume, 12.5 parts of magnesium sulfate heptahydrate, 0.3 part of citric acid, 0.5 part of dolomite fine powder, 0.2 Part glass fiber, 0.1 part sodium sulfate, 0.4 part polyamide polyurea resin.

[0031] The method for preparing the experimental block with low-cost heat-resistant magnesium cement of the present invention, the specific operation steps are as follows:

[0032] 1) Raw materials are pre-mixed, weigh the whole formula amount of low-grade ore light-burned magnesia powder, silica fume, magnesium sulfate heptahydrate, dolomite fine powder, heat-resistant fiber and water-repellent agent and put them into the 80 rpm The mixer is used for dry mixing, and the mixing time is 5 minutes;

[0033] 2) Dissolve the admixture, weigh all the modifiers and early strength agents in the formula and put them into the mixer,...

Embodiment 2

[0039]A new low-cost heat-resistant magnesium cement, the raw material composition of the new heat-resistant material is as follows: it is characterized in that it contains the following components by weight: 56 parts of light-burned magnesium oxide powder, 30 parts of silicon, 12.5 parts of magnesium sulfate heptahydrate 0.2 part of oxalic acid, 0.2 part of citric acid, 0.15 part of glass fiber, 0.15 part of sodium sulfate, 0.1 part of ferric chloride, 0.35 part of polyamide polyurea resin, and 0.35 part of dolomite fine powder.

[0040] The method for preparing the experimental block from the low-cost heat-resistant magnesium cement in Example 2 is as in Example 1.

Embodiment 3

[0042] A new type of low-cost heat-resistant magnesium cement. The raw material composition of the new type of heat-resistant material is as follows: it contains the following components by weight: 62.5 parts of light-burned magnesium oxide powder, 26 parts of silica fume, 10 parts of magnesium sulfate heptahydrate, phosphoric acid 0.25 parts, 0.25 parts of oxalic acid, 0.2 parts of polyamine polyamide, 0.1 parts of asbestos, 0.1 parts of glass fiber, 0.1 parts of ferric chloride, 0.5 parts of dolomite fine powder.

[0043] The method for preparing the experimental block from the low-cost heat-resistant magnesium cement in Example 3 is as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com