Steel rings for tire vulcanization and tank models for medium and small tire vulcanization

A tire vulcanization, small and medium-sized technology, applied in the field of tire vulcanization, can solve the problem that the vulcanization tank cannot produce small and medium-sized tires, etc., and achieve the effect of expanding the production range and flexible production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

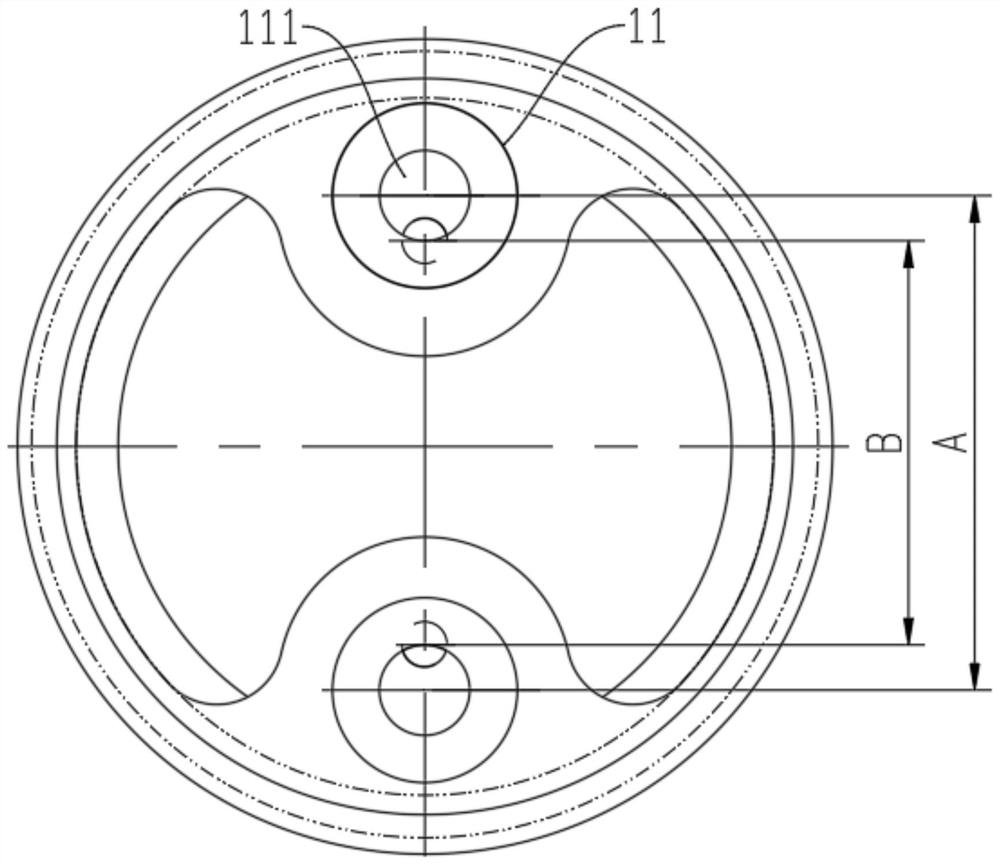

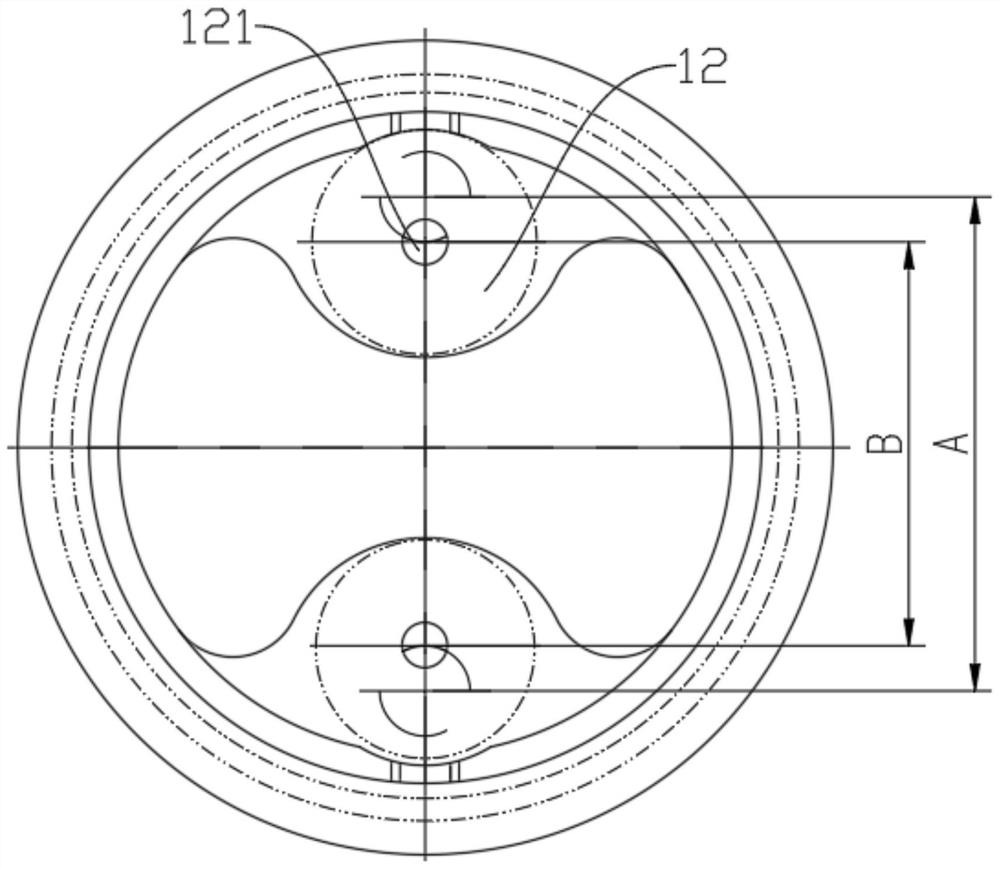

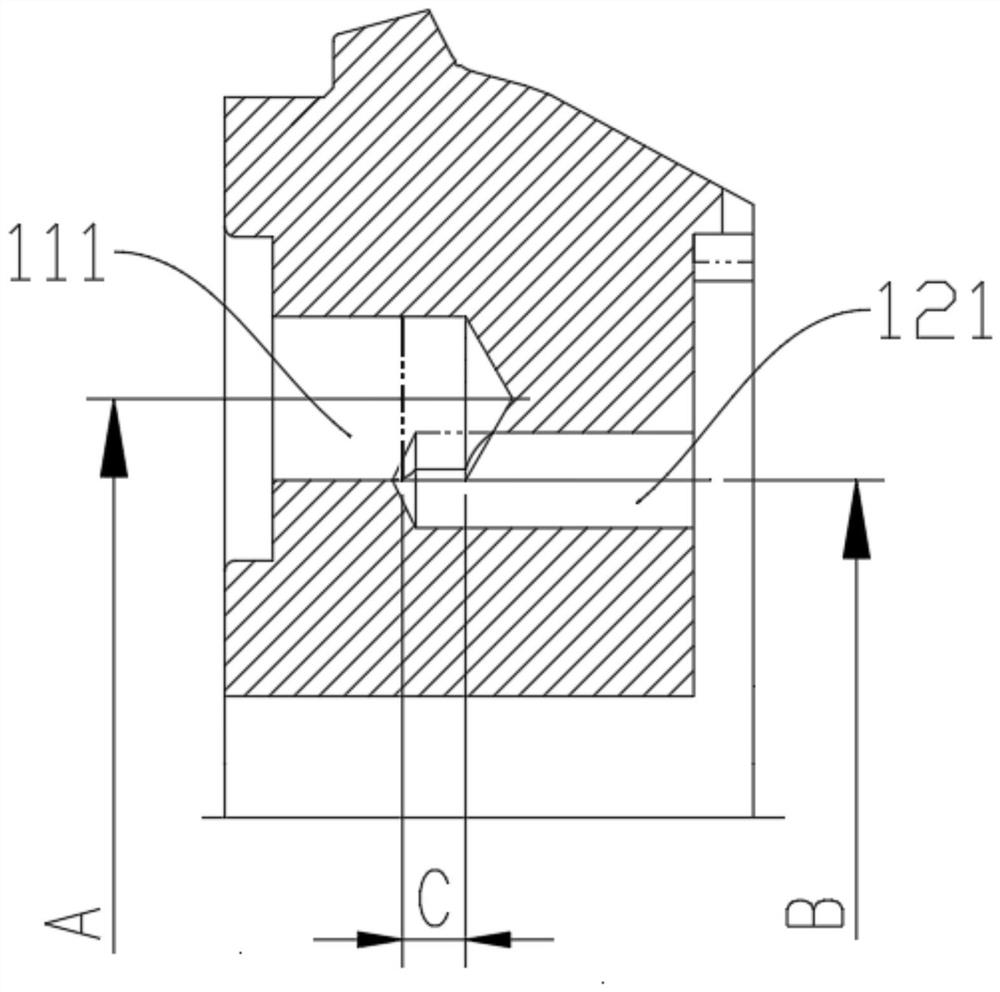

[0033] Please refer to Figure 1 to Figure 3 , the embodiment of the present application provides a steel ring for tire vulcanization, which is used for vulcanizing small and medium-sized tires in a vulcanization tank. One side of the steel ring for tire vulcanization is provided with two water nozzle seats 11, and the water nozzle seats 11 There is a nozzle seat bottom hole 111 symmetrical to the axis of the steel ring for tire vulcanization, and a seal ring seat 12 is provided on the opposite side of the steel ring for tire vulcanization. The axisymmetric sealing ring seat bottom hole 121 of the steel ring for vulcanization is connected with a faucet seat bottom hole 111 respectively;

[0034] The center distance between the two nozzle seat bottom holes 111 is greater than the center distance between the two sealing ring seat bottom holes 121, one of the water nozzle seat bottom holes 111 is used to connect with the water inlet pipe of the vulcanization tank and serves as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com