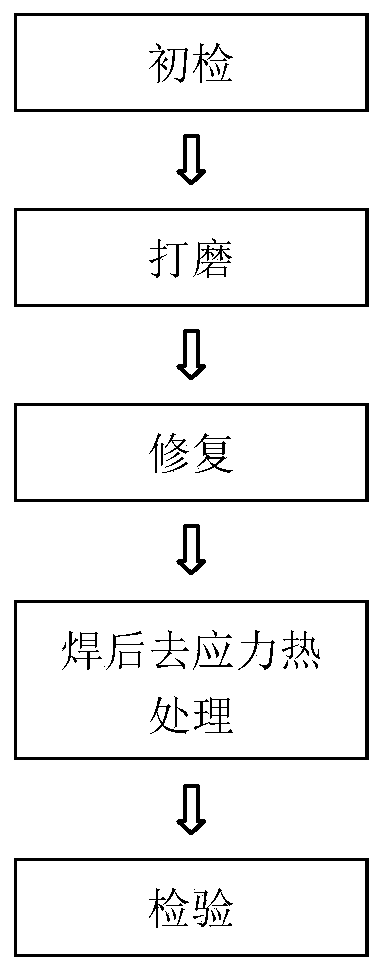

Typical part defect repairing method for tail nozzle mechanical adjusting system

A technology for mechanical adjustment and defect repair, applied in aircraft parts, laser welding equipment, transportation and packaging, etc., can solve problems such as poor weldability, easy cracks, bubbles, etc., and achieve strong operability, improved strength, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

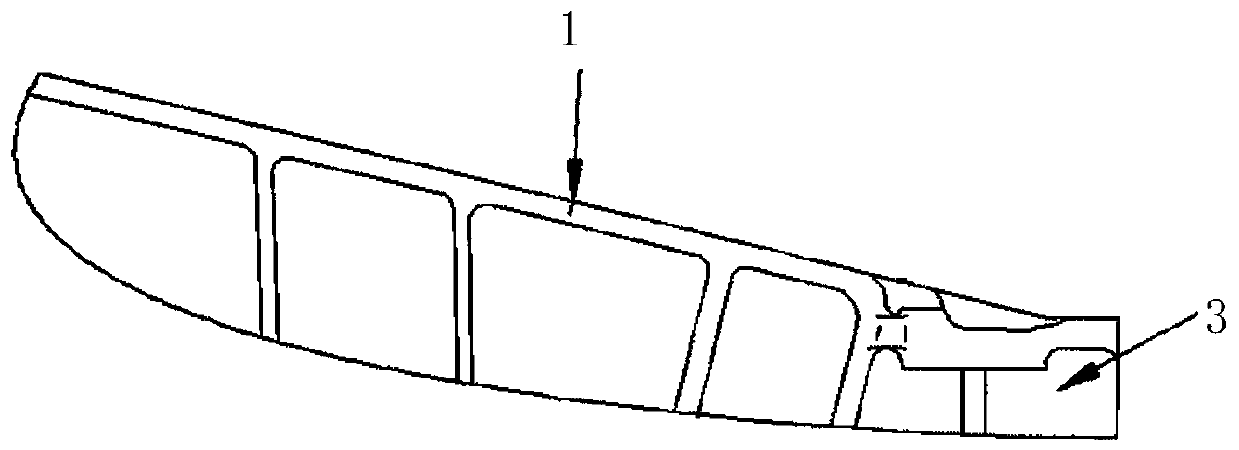

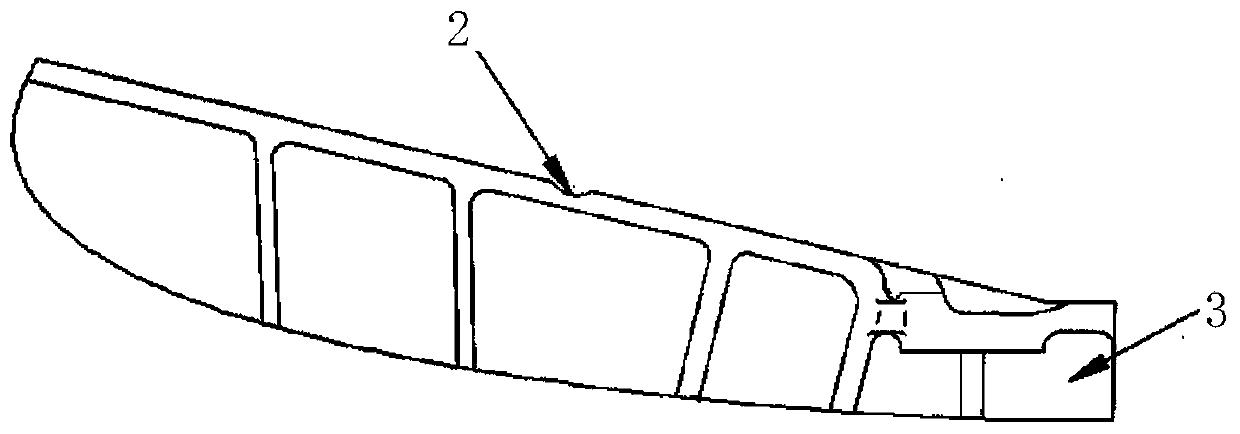

[0030] In order to solve the problems existing in the existing technology, such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a method for repairing the defect of the typical part 3 of the tail nozzle mechanical adjustment system, including the following steps:

[0031] S1, such as figure 2 As shown in the initial inspection, the typical piece 3 with crack 1 is subjected to fluorescent inspection to determine the position, length and depth of crack 1.

[0032] S2, such as image 3 As shown, grinding, grinding the crack 1, the crack 1 is polished to form an open groove 2, and the oxides on the open groove 2 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com