Fixture and processing method for special-shaped groove of thin-walled parts

A processing method and technology for special-shaped grooves, which are applied in metal processing, metal processing equipment, household appliances, etc., can solve the problems of high cost, inability to guarantee processing accuracy, low efficiency, etc., and achieve no material damage, ensure dimensional accuracy and surface quality. , the effect of huge benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

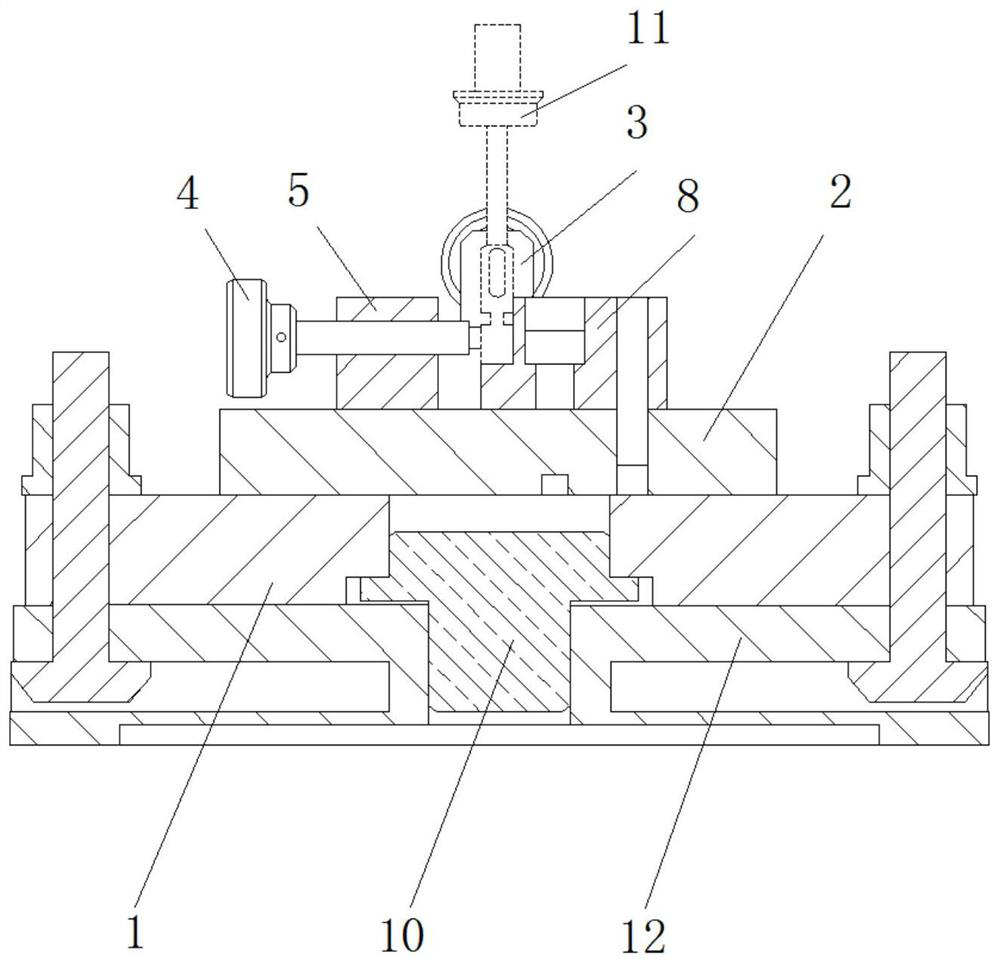

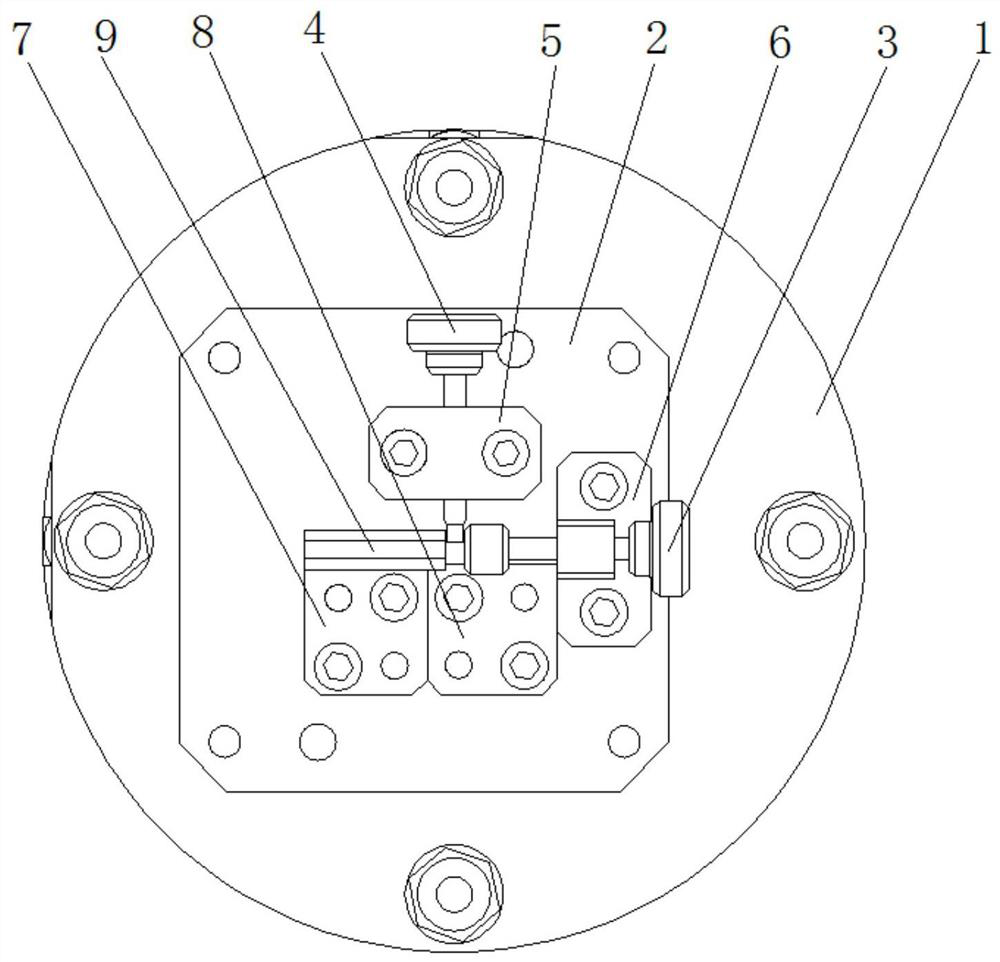

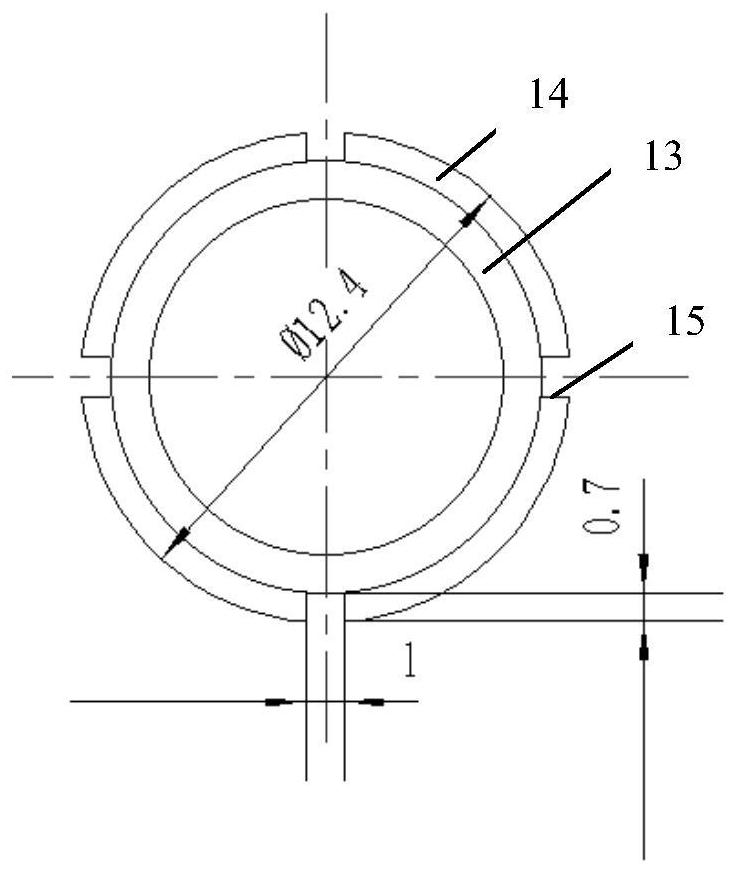

[0033] Such as Figure 1 to Figure 6 As shown, a fixture for special-shaped grooves of thin-walled parts includes a fixture base 1, and the fixture base 1 is uniformly provided with positioning through holes along the circumferential direction. The fixture base 1 is circular, and the upper surface of the fixture base 1 is fixed by bolts. The support platform 2, the support platform 2 is square, the first mounting seat 5 and the second mounting seat 6 are fixedly installed on the support platform 2 by bolts, and the first mounting seat 5 and the second mounting seat 6 are vertically arranged, the first The mounting base 5 is screwed with a Y-direction clamping rotation rod 4, and the boss of the second mounting base 6 is equipped with an X-direction clamping rotation rod 3, and the Y-direction clamping rotation rod 4 is perpendicular to the X-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com