A stable reaction furnace for producing pvc and its working method

A reaction furnace and stable technology, which is applied in the field of stable reaction furnaces for producing PVC, can solve the problems that the reaction furnace does not have a high degree of automation, does not have the detection and adjustment of thermal energy in the furnace, and the reaction rate is biased. Rapid decay, reduced risk of operational errors, improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

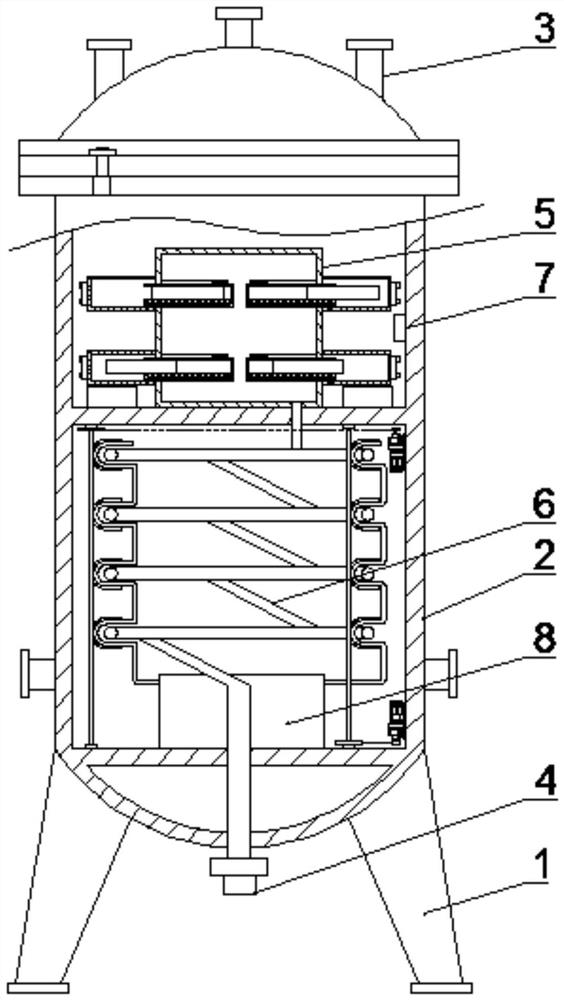

[0037] Such as Figure 1-6 A stable reactor for producing a PVC, comprising: a base bracket 1, a reactive furnace body 2, a feed port 3, a discharge port 4, a heating bin 5, and a cooling boon 6, the base bracket 1 top The reactive furnace body 2 is provided, and the feed port 3 is provided at the top of the reaction furnace body 2, and the feed port 3 is connected to a heating position 5, and the heating bin 5 is disposed in the reaction furnace body 2, the The bottom connection of the heating warehouse 5 is provided with a cooling position 6, which is disposed in the reaction furnace body 2, and the cooling boon 6 is provided with a discharge port 4, the outlet 4 is disposed in the reaction furnace body 2. bottom.

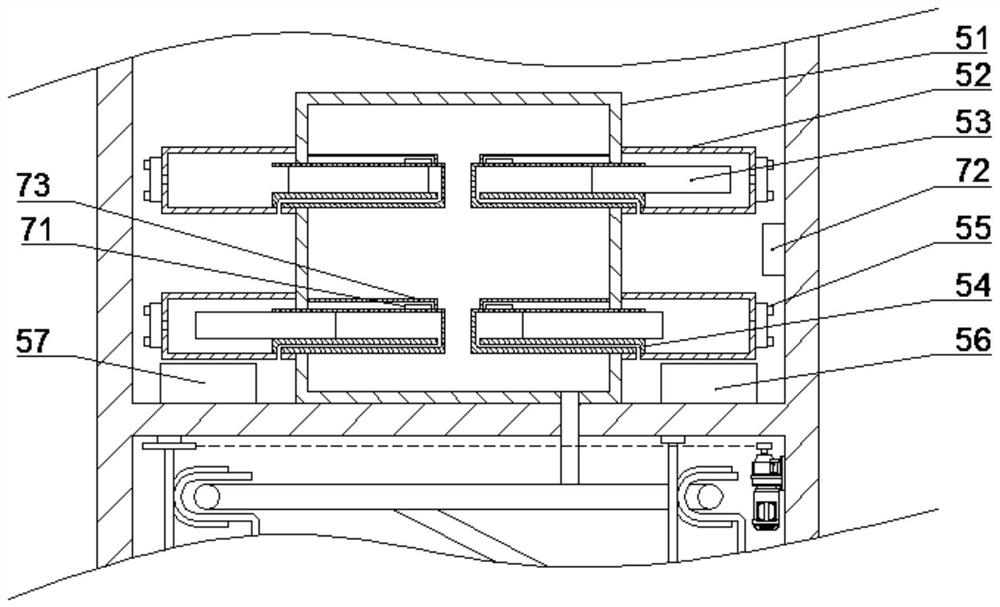

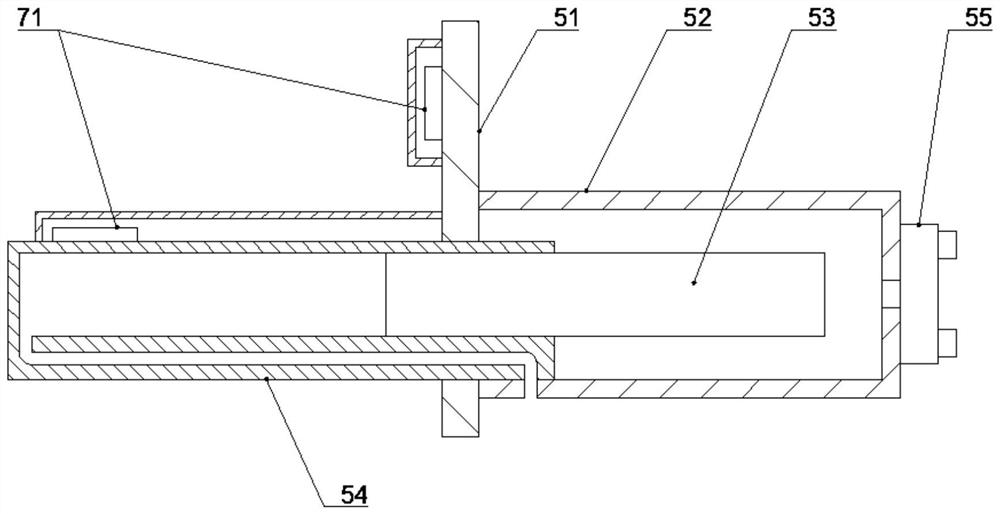

[0038]The heating bin 5 described in this embodiment includes a hot bin housing 51, a heater trash body 52, a heating rod 53, a sleeve 54, a gas path valve 55, a gas pump 56, and a pump 57, the heat club housing. 51 is disposed in the reaction furnace body 2, the top ...

Embodiment 2

[0051] Such as Figure 1-3 A stable reactor for producing a PVC, comprising: a base bracket 1, a reactive furnace body 2, a feed port 3, a discharge port 4, a heating bin 5, and a cooling boon 6, the base bracket 1 top The reactive furnace body 2 is provided, and the feed port 3 is provided at the top of the reaction furnace body 2, and the feed port 3 is connected to a heating position 5, and the heating bin 5 is disposed in the reaction furnace body 2, the The bottom connection of the heating warehouse 5 is provided with a cooling position 6, which is disposed in the reaction furnace body 2, and the cooling boon 6 is provided with a discharge port 4, the outlet 4 is disposed in the reaction furnace body 2. bottom.

[0052] The heating bin 5 described in this embodiment includes a hot bin housing 51, a heater trash body 52, a heating rod 53, a sleeve 54, a gas path valve 55, a gas pump 56, and a pump 57, the heat club housing. 51 is disposed in the reaction furnace body 2, the top...

Embodiment 3

[0056] Such as figure 1 , 4 A stable reactor for producing PVC, including: base bracket 1, reactive furnace body 2, feed port 3, discharge port 4, heating warehouse 5, and cooling bin 6, said The base bracket 1 is fixedly provided with a reactive furnace body 2, and a feed port 3 is provided at the top of the reactive furnace body 2, and the feed port 3 is connected to a heating position 5, the heating bin 5 is disposed in the reaction furnace body 2. Inside, the heating warehouse 5 is provided with a cooling boon 6, and the cooling boon 6 is provided in the reaction furnace body 2, and the bottom connection of the cooling boon 6 is provided with a discharge port 4, and the material port 4 is disposed. Reactive furnace body 2 bottom.

[0057] The cooling bin 6 described in this embodiment includes a fluid passage 61, a cooler 62, a heat sink 63, and a circulating water cold tube 64, and one end of the conductive passage 61 connects to the heating bin 5, the guiding channel 61 othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com