Liquid metal/polymer composite material and its preparation method and electronic device

A technology of liquid metal and composite materials, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, electrical components, cables/conductors, etc., can solve the problems of no good conductive path, low conductivity of composite materials, high cost of use, etc. , to achieve the effect of good connectivity between frames, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

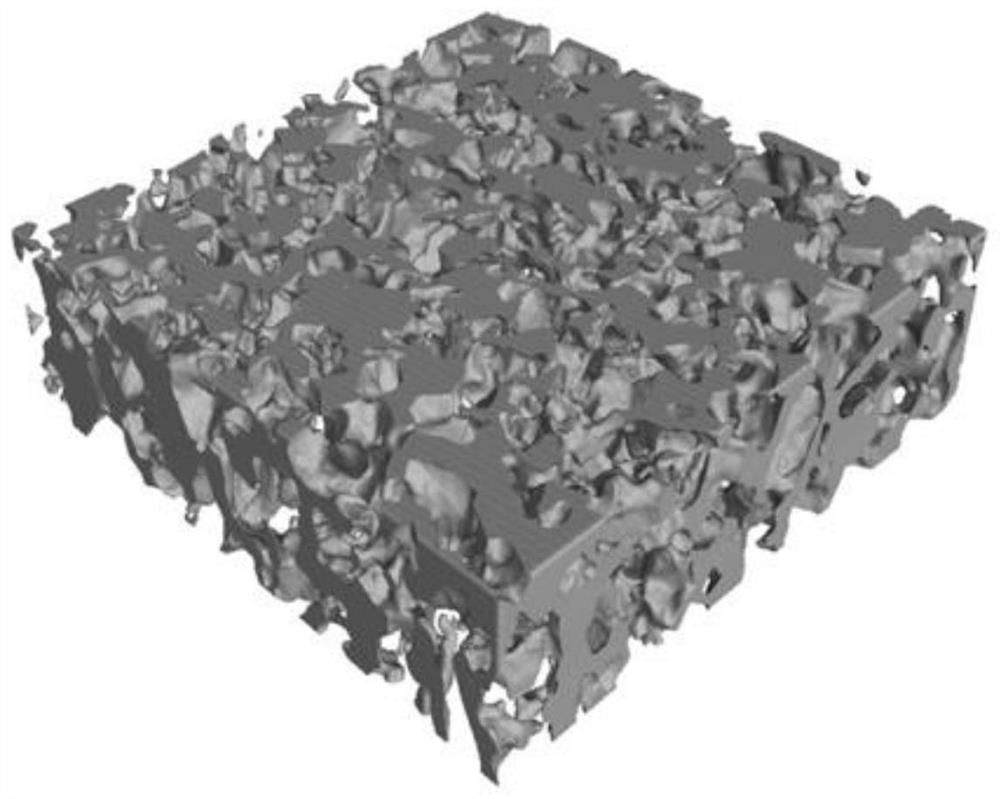

[0030] This embodiment provides a liquid metal / polymer composite material, using sugar particles as a template material, the liquid metal is a gallium indium eutectic alloy with a melting point of 15°C, and the polymer is a silicone elastomer (Ecoflex00-30). The specific implementation The process is as follows:

[0031] (1) Preparation of sugar block template: using commercially available sugar granules as raw materials, mix sugar granules and deionized water at a mass ratio of 10: (1-2), and stir evenly. Use a press to apply a uniaxial pressure of 50-200MPa to the granules, keep the pressure for 5-20 minutes, and then unload the pressure to obtain a candy with hand-held mechanical properties, and sinter the candy at 60-80°C for 12-20 hours to obtain a candy template.

[0032] (2) Preparation of gallium-indium eutectic alloy: heat and melt Ga and In at 30-200°C respectively, then mix the two evenly according to the mass ratio Ga / In=75:25, and obtain gallium with a melting po...

Embodiment 2

[0039] This embodiment provides a liquid metal / polymer composite material. Sugar particles are used as template materials. The liquid metal is a gallium indium tin eutectic alloy with a melting point of 10°C. The polymer is a silicone elastomer (Ecoflex00-30). The implementation process is as follows:

[0040] (1) Preparation of sugar block template: using commercially available sugar granules as raw materials, mix sugar granules and deionized water at a mass ratio of 10: (1-2), and stir evenly. Use a press to apply a uniaxial pressure of 50-200MPa to the granules, keep the pressure for 5-20 minutes, and then unload the pressure to obtain a candy with hand-held mechanical properties, and sinter the candy at 60-80°C for 12-20 hours to obtain a candy template.

[0041] (2) Preparation of gallium indium tin eutectic alloy: heat and melt Ga, In and Sn at 30-300°C respectively, then mix the three evenly according to the mass ratio Ga / In / Sn=62:22:16, after cooling, A gallium-indiu...

Embodiment 3

[0045] This embodiment provides a liquid metal / polymer composite material, using sodium chloride particles as the template material, the liquid metal is gallium metal with a melting point of 29.6°C, and the polymer is silica gel elastomer (Ecoflex00-30). The specific implementation process as follows:

[0046] (1) Preparation of sodium chloride block template: using commercially available sodium chloride granules as raw material, mix sodium chloride granules and deionized water at a mass ratio of 10: (3-5), and stir evenly. Use a press to apply a uniaxial pressure of 100-200 MPa to the particles, keep the pressure for 20-30 minutes, and then unload the pressure to obtain a sodium chloride block with hand-held mechanical properties, and sinter the sodium chloride block at 100-150 ° C for 24-32 hours, Thereby obtaining a sodium chloride block template.

[0047] (2) Preparation of gallium metal: heating and melting Ga at 50-300°C respectively to obtain gallium metal with a melti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com