High-temperature rotor system axial force testing system and method

A testing system and axial force technology, applied in the testing of mechanical parts, the testing of machine/structural parts, and the measurement of force, etc., can solve the problems of limited use of the rotor system and inapplicability of the rotor system, and achieve long service life and simplification. Test procedure, effect of simplified rotor system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention is further explained.

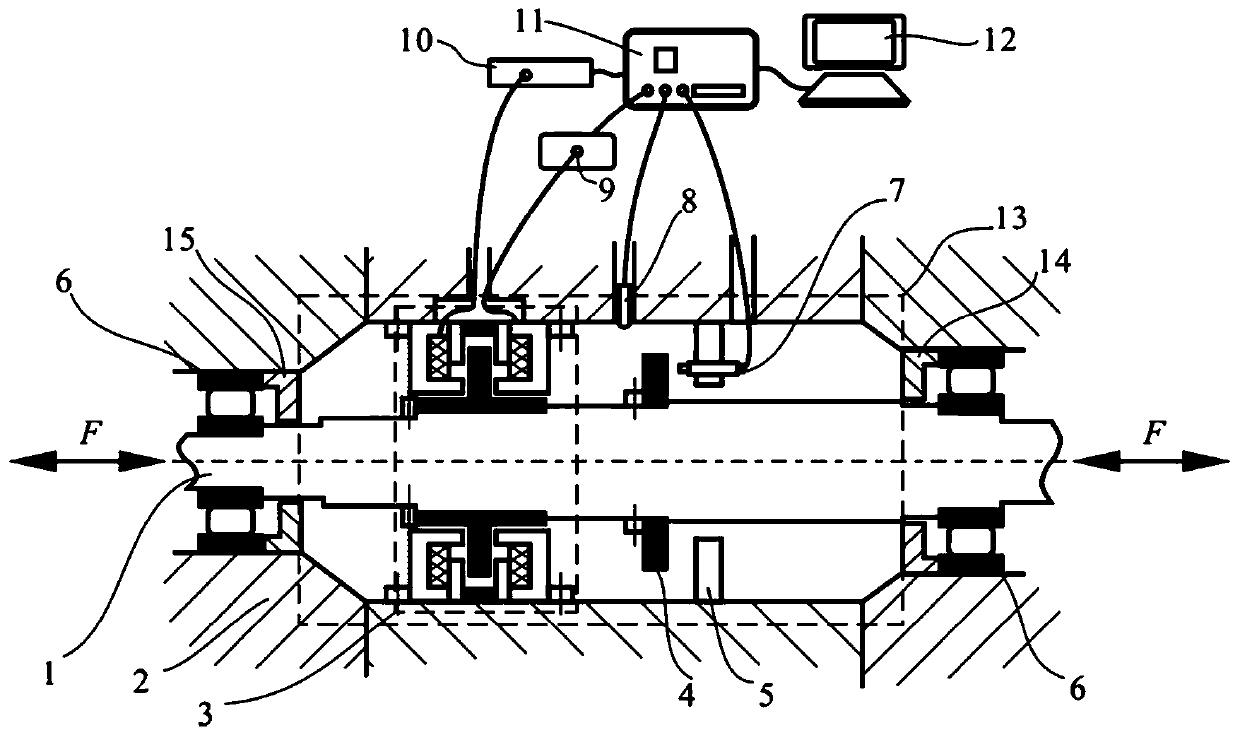

[0032] Such as figure 1 Shown is a structural diagram of a test system for measuring the bidirectional axial force of a certain rotor system provided by the present invention.

[0033] The system includes a rotating shaft (1), a base (2), an electromagnetic device (3), a displacement plate (4), a sensor mount (5), a radial bearing (6), a displacement sensor (7), a temperature sensor (8 ), current sensor (9), power amplifier (10), control system (11), and PC (12).

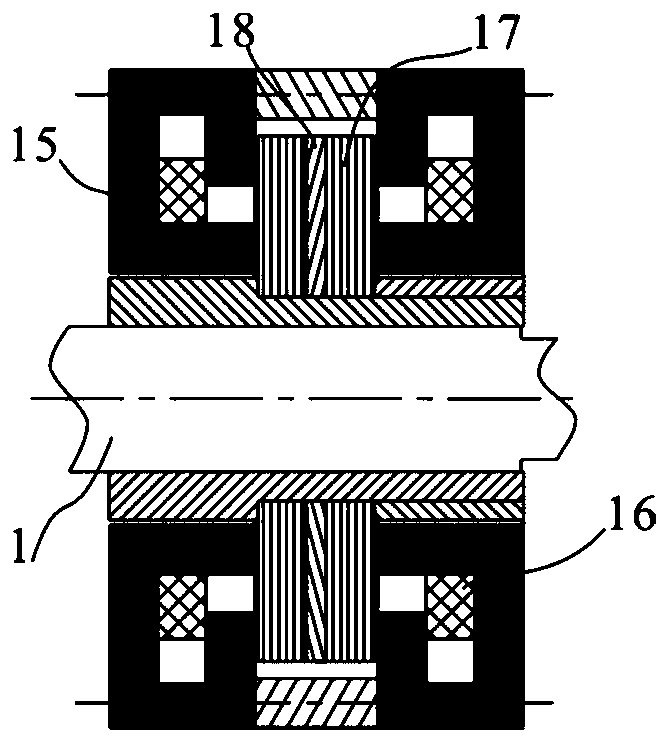

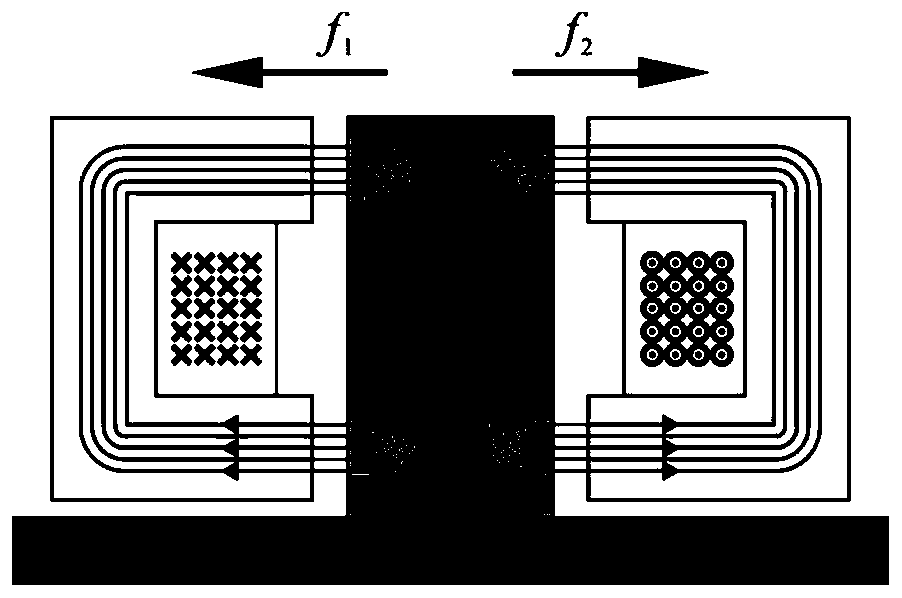

[0034] The electromagnetic device (3) includes a stator (15), a coil (16) wound in the slot of the stator (15), suction disks (17) arranged symmetrically with the stator (15), and spacers between the suction disks. disk (18); after the coil (16) is energized, the stator (15) and the suction disk (17) form a magnetic circuit to generate electromagnetic attraction; the electromagnetic force formed between the stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com