Self-release glaze inducer, self-release glaze ceramic tile and preparation method thereof

A technology of self-releasing glaze and inducer, applied in the direction of coating, etc., can solve the problems of surface hardness, insufficient wear resistance, undurability, cracking of glaze surface, etc., and achieve good flatness, strong universality, Smooth and delicate surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

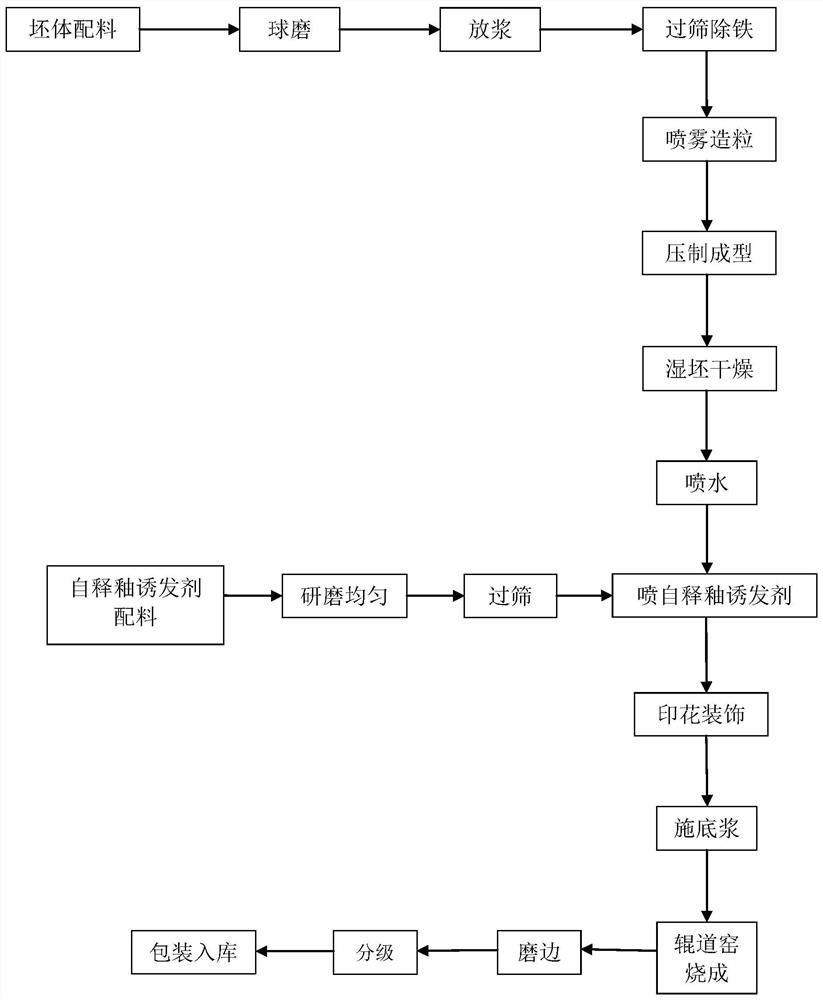

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 A kind of preparation method of self-releasing glaze ceramic brick

[0044] A preparation method for self-releasing glazed ceramic tiles, comprising the following steps:

[0045] A. Prepare green body:

[0046] The chemical composition of the body is shown in Table 1.

[0047] Table 1, the chemical composition list of green body (weight percent, %)

[0048] components SiO 2

Al 2 o 3

CaO Fe 2 o 3 +TiO 2

MgO K 2 o

Na 2 o

Li 2 o

burn reduction 1# 66.5 15 4 1 3 4 1 0.6 4.9 2# 68 16.6 2.5 1.5 2 3 3 0.4 3 3# 69.5 18 1 2 1 2 2 0.2 4.3 4# 67 16.5 3 1.5 2.6 2.5 2.6 0.3 4 5# 67.5 16 2 1 3 3.5 1.5 0.5 5

[0049] Preparation of green body: select clay, ceramic waste residue, diopside, talc, glass powder, spodumene and auxiliary raw materials with an additional weight percentage of 1% to 3% according to the chemical composition of Table 1 for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com