Protection method of controller circuit board

A circuit board and controller technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of difficult promotion, complicated curing reaction process, high cost of adhesive production, etc. The effects of wide area, improved working environment for workers, good chemical stability and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A protection method for a controller circuit board, comprising the steps of:

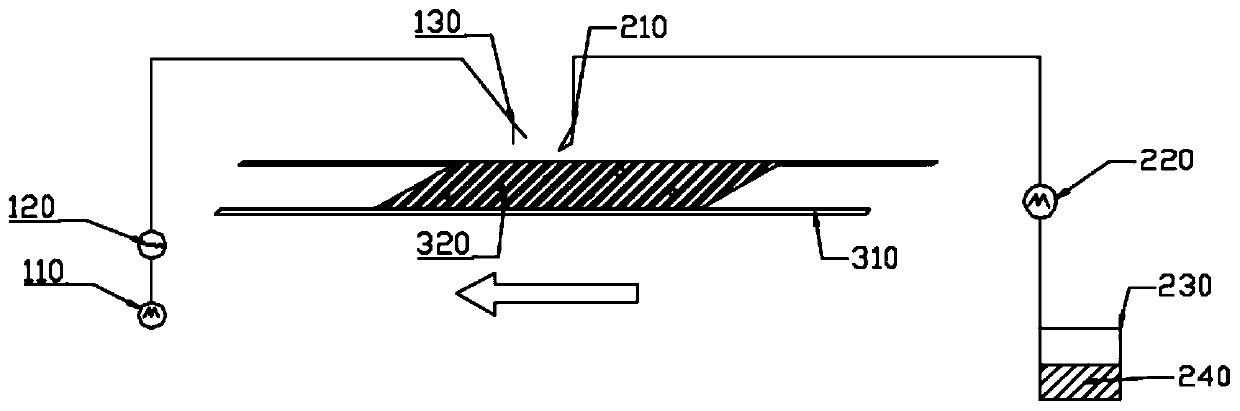

[0035] (1) The circuit board enters the gluing system under the drive of the assembly line crawler belt 310, and the gluing nozzle 210 sprays hot melt adhesive on the circuit board, wherein the hot melt adhesive is polyurethane hot melt adhesive, and the polyurethane hot melt adhesive is melted The glue tank 230 is melted into a glue liquid 240, and the glue liquid 240 enters the glue application nozzle 210 through the glue application pressurization motor 220. The glue application nozzle 210 is a flat fan-shaped nozzle, and the gap width of the glue application nozzle 210 is 1-500 μm , the length is 1-50mm, the size of the gluing nozzle 210 is adjusted according to the size of the circuit board, which can meet the gluing operation of different main board sizes and different film thickness requirements, the temperature of the sprayed polyurethane hot melt adhesive is 200 ℃, The nozzle 210 ado...

Embodiment 2

[0038] A protection method for a controller circuit board, comprising the steps of:

[0039] (1) The circuit board enters the gluing system driven by the assembly line crawler 310, and the gluing nozzle 210 sprays hot melt adhesive on the circuit board, wherein the hot melt adhesive is polyethylene hot melt adhesive, polyethylene hot melt adhesive Melt into the glue liquid 240 in the melting glue box 230, the glue liquid 240 enters the glue application nozzle 210 through the glue application pressurization motor 220, and the described glue application nozzle 210 is a flat fan nozzle, and the gap width of the glue application nozzle 210 is 1 -500μm, the length is 1-50mm, the size of the gluing nozzle 210 can be adjusted according to the size of the circuit board, which can meet the gluing operation of different board sizes and different film thickness requirements. The temperature of the sprayed polyethylene is 100 ℃, The nozzle 210 adopts an automatic control program, and can ...

Embodiment 3

[0042] A protection method for a controller circuit board, comprising the steps of:

[0043] (1) The circuit board enters the gluing system driven by the assembly line crawler belt 310, and the gluing nozzle 210 sprays hot melt adhesive on the circuit board, wherein the hot melt adhesive is polyamide hot melt adhesive, polyamide hot melt adhesive Melt into the glue liquid 240 in the melting glue box 230, the glue liquid 240 enters the glue application nozzle 210 through the glue application pressurization motor 220, and the described glue application nozzle 210 is a flat fan nozzle, and the gap width of the glue application nozzle 210 is 1 -500μm, the length is 1-50mm, the size of the gluing nozzle 210 is adjusted according to the size of the circuit board, which can meet the gluing operation of different board sizes and different film thickness requirements, and the temperature of the sprayed polyamide hot melt adhesive is 250 ℃ , the gluing nozzle 210 adopts an automatic contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com