Air-cooled axle-controlled traction inversion power unit with double-sided heat dissipation

A power unit, double-sided heat dissipation technology, applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., can solve the problem of inability to install cooling tower water cooling system, reduced heat dissipation effect of devices, and occupied size Large and other problems, to achieve the effect of improving the anti-fault ability, high adhesion utilization rate, and less traction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

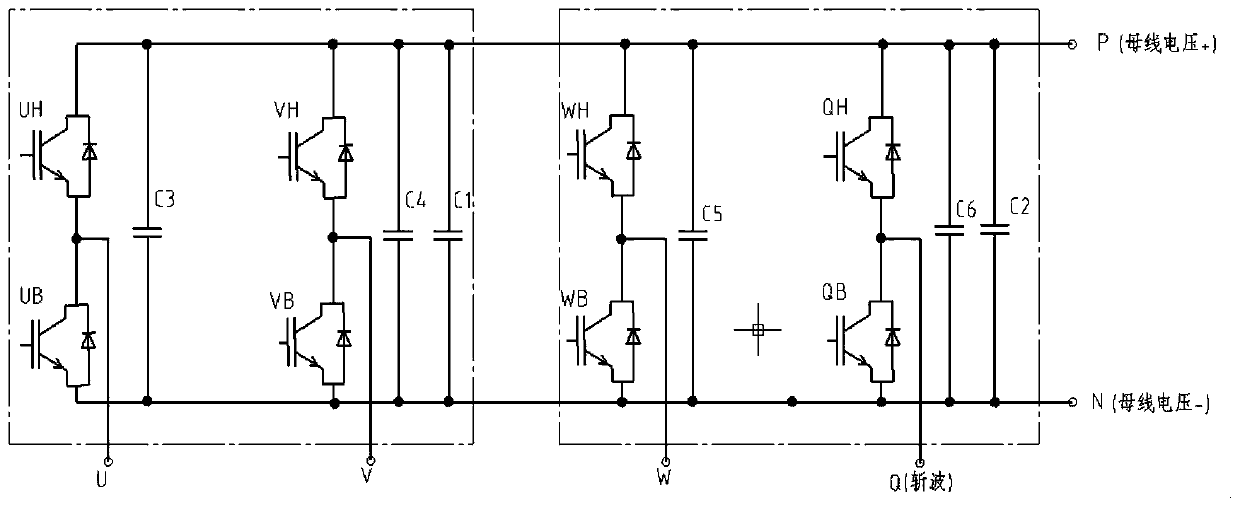

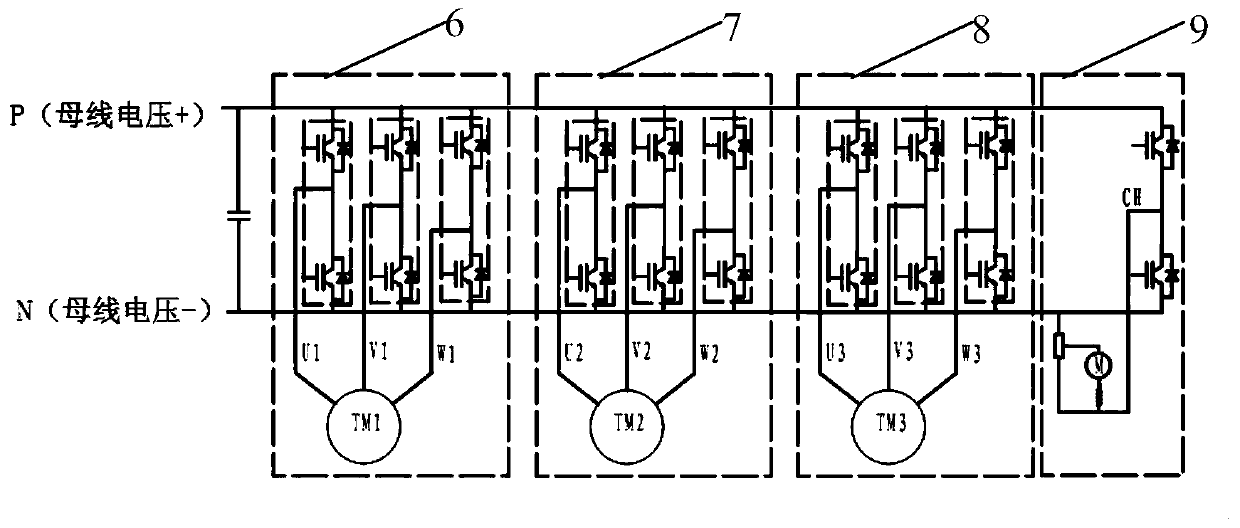

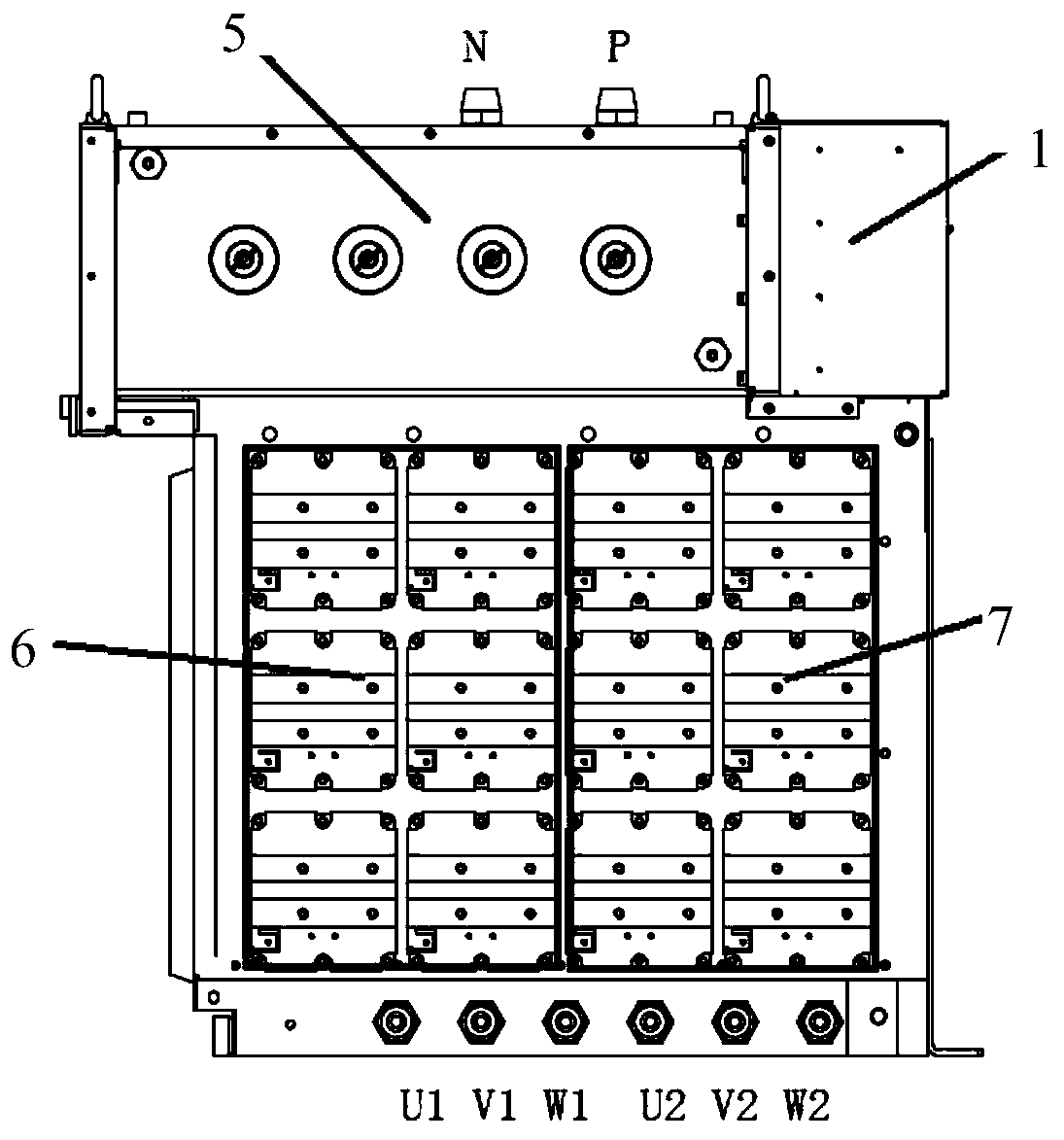

[0030] see Figure 2-6 As shown, the present invention provides an air-cooled shaft-controlled traction inverter power unit with double-sided heat dissipation, including: a main body of the power unit and a supporting frame installed outside the main body of the power unit, the front surface of the supporting frame is from top to The drive control box 1 and the main air duct 2 are distributed below, and the left and right sides of the support frame are correspondingly installed with a left cover 3 and a right cover 4;

[0031] The top of the main body of the power unit is provided with supporting capacitors 5, and the supporting capacitors 5 are installed on the top of the supporting frame, and each supporting capacitor 5 is connected to a capacitor busbar, and the P / N terminal on the capacitor busbar provides DC power for the inverter circuit; A heat pipe radiator is respectively installed on both sides of the main air duct 2, and one end of the heat pipe radiator extends int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com