Split type six-phase motor control system integrated with alternating current charging and method thereof

A motor control and AC charging technology, applied in the direction of AC motor control, control system, motor, etc., can solve the problems of large volume, complex system, long single-phase AC charging time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

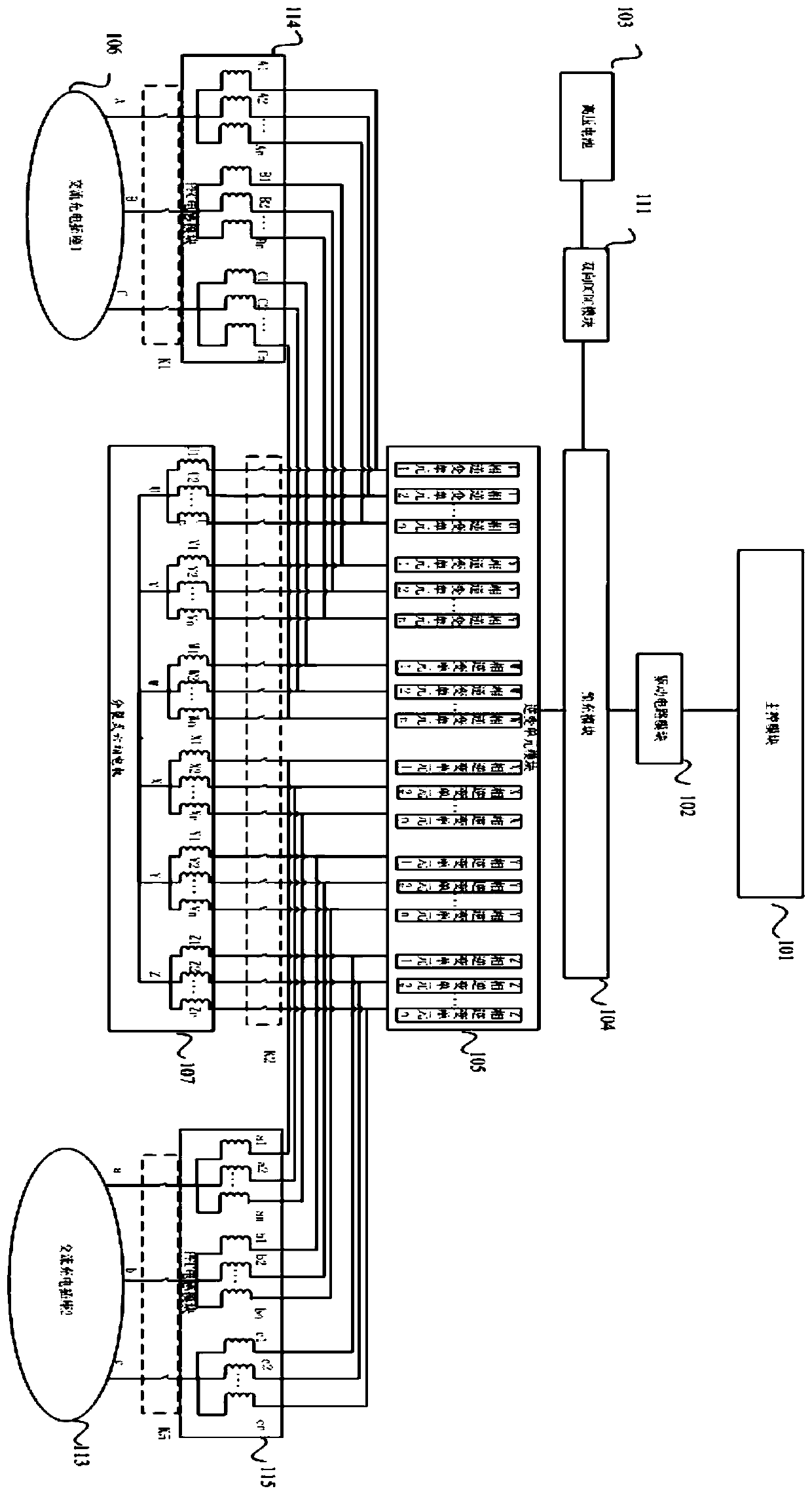

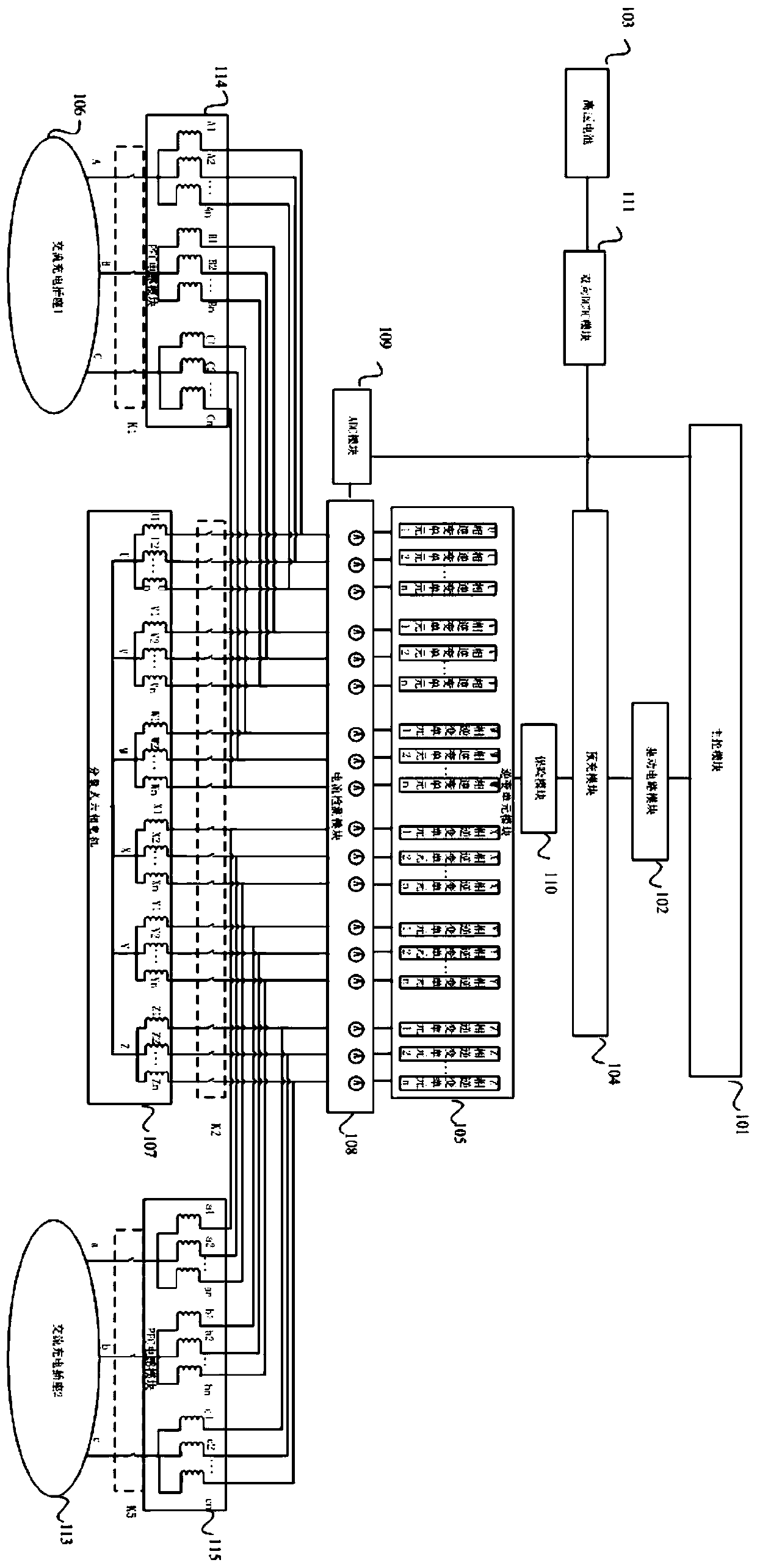

[0035] This case discloses a split-type six-phase motor control method integrating AC charging, the main control module is respectively connected to the control terminals of the inverter unit module, the pre-charging module, the motor control switch and the AC control switch , to control its opening and closing;

[0036] Wherein, when the system is in the drive mode, the inverter unit module outputs electric energy to the motor drive circuit, and when the motor control switch is in a closed state, the AC control switch is turned off;

[0037] Conversely, when the system is in the charging mode, the external AC power supply inputs electric energy to the current conversion module through the AC charging socket, the AC control switch is in the closed state, and the motor control switch is turned off.

[0038] In this case, the power input end of each single motor in the six-phase motor is equipped with multiple motor inductors, and the motor is connected to multiple inverter unit...

Embodiment 2

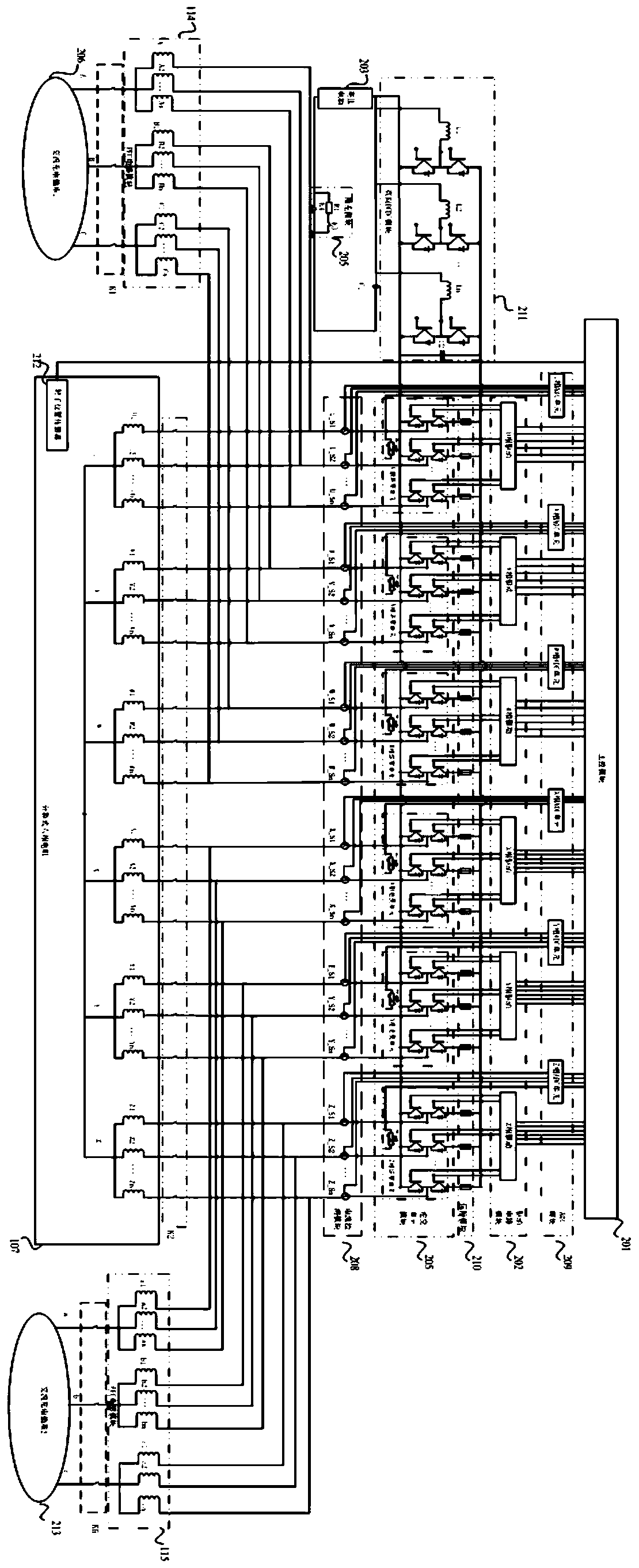

[0041] Specifically, the main control unit module ( figure 2 (not shown) are respectively connected to the low-voltage signal output terminals of the AC charging socket 205 to receive the low-voltage signal in the charging socket. The main control unit module judges the working mode according to the received low-voltage signal or the signal of the vehicle controller.

[0042] For example, when the charging gun of an electric vehicle is connected to the AC charging socket, the low-voltage signal of the charging gun will activate the low-voltage control power supply on the main control unit module. After the main control unit module is powered on, it will switch the working mode of the system to the charging mode .

[0043] Afterwards, the main control unit module detects that the charging gun is connected to the system, and conducts information interaction with the charging pile through the PWM signal in the charging gun to confirm the power supply capability of the charging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com