Transformer fireproof device with heat dissipation function

A fire prevention device and transformer technology, applied in the field of transformers, can solve the problems of reducing the service life of transformers, causing fires, property damage, etc., and achieve the effect of reducing temperature and reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

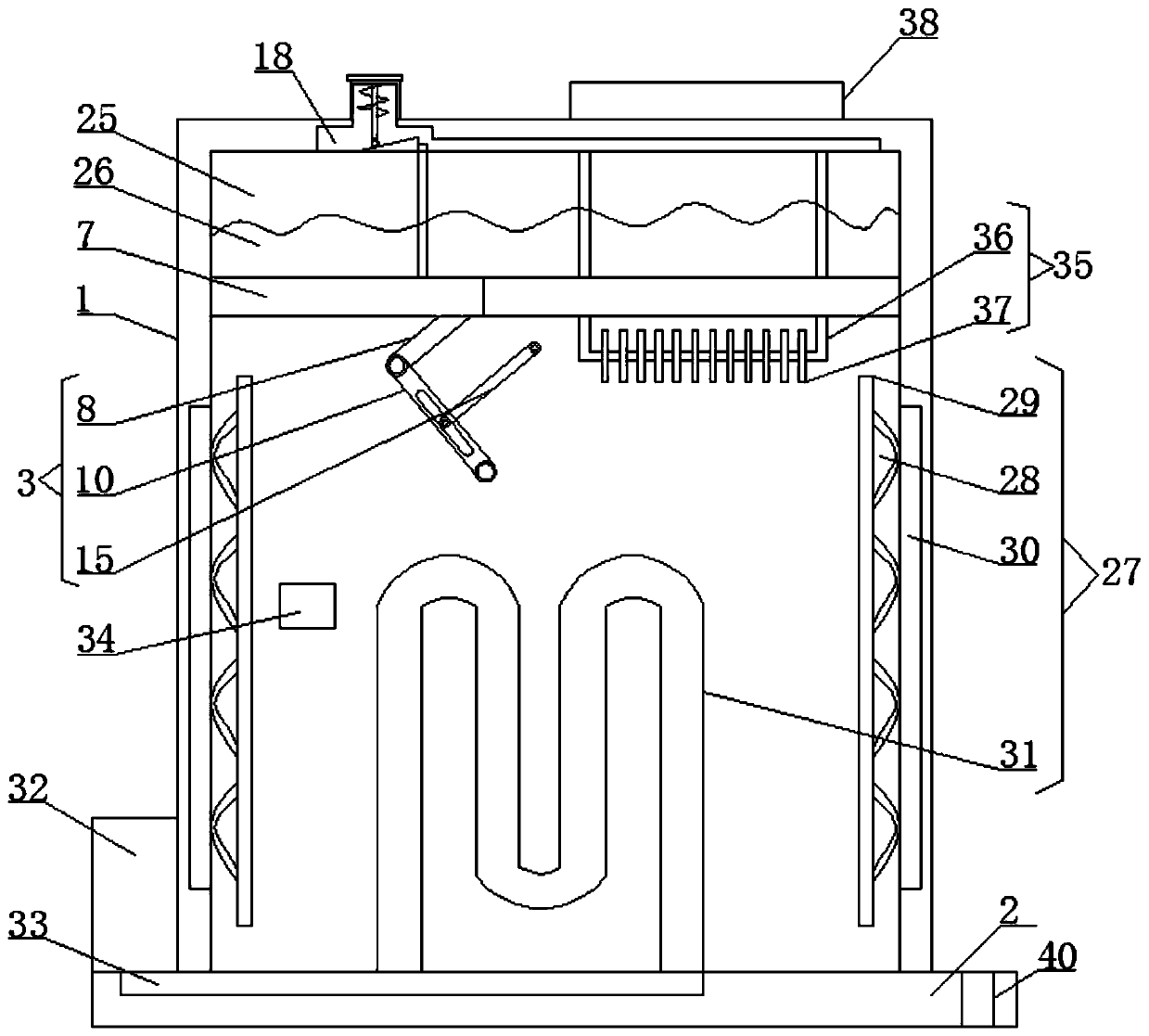

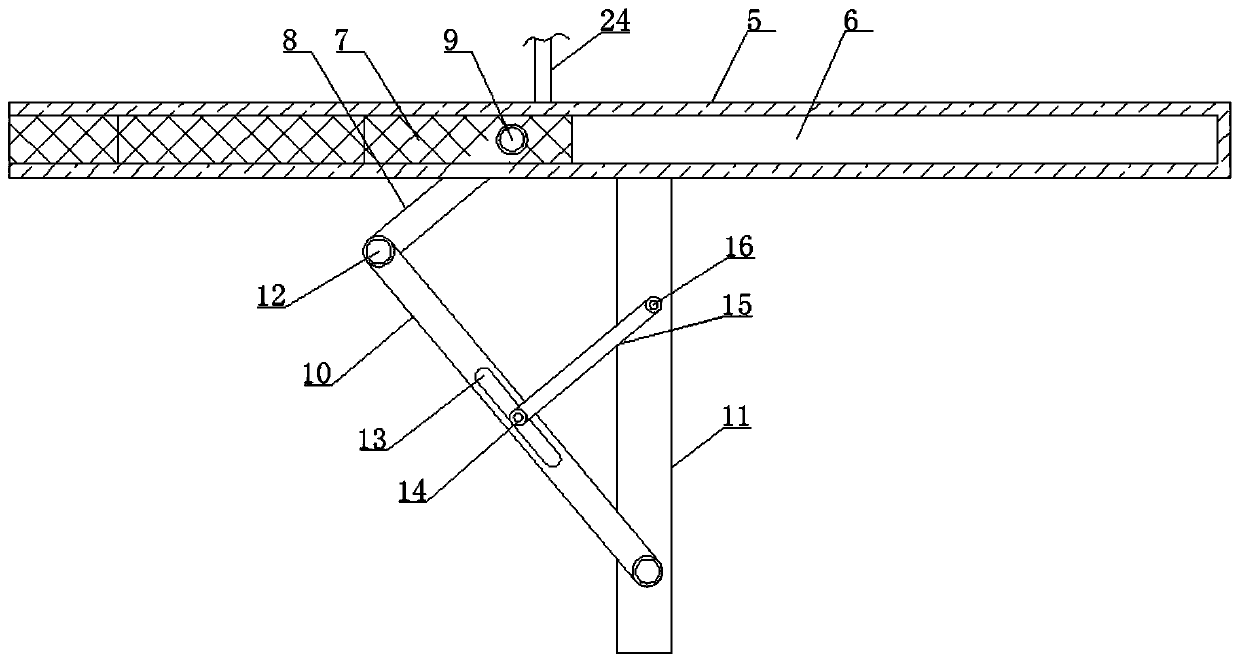

[0028] Such as Figure 1-4 As shown, the transformer fire protection device with heat dissipation function according to the embodiment of the present invention includes a transformer box 1 and a mounting seat 2 located at the bottom of the transformer box 1, and the transformer box 1 is a cavity structure with a lateral opening , and the top of the transformer box 1 is provided with a fireproof mechanism 3, and the fireproof mechanism 3 includes a connection block 1 4 and a connection block 2 5 arranged laterally symmetrically on both sides of the transformer box 1, A side of the connecting block one 4 and the connecting block two 5 close to each other is provided with a chute 6, and the transformer box 1 is provided with a telescopic plate 7 connected with two groups of the chute 6, and the The bottom end of the telescopic plate 7 is provided with an obliquely arranged movable rod 8, and the movable rod 8 is connected with the described telescopic plate 7 by a roller 9, and t...

Embodiment 2

[0030] Such as Figure 1-4As shown, the heat dissipation mechanism 27 includes heat dissipation strips 28 located on both sides of the inner wall of the transformer box body 1, and the sides of the heat dissipation strips 28 that are close to each other are provided with matching heat dissipation plates 29, and the transformer box body There are heat collecting chambers 30 on both sides of the inner wall of 1, wherein the heat dissipation mechanism 27 also includes a cooling pipe 31 located on one side of the inner wall of the transformer box 1, the cooling pipe 31 is arranged in a curved shape, and the transformer box 1 and at the top of the mounting base 2 is provided with a cooling box 32 , and the cooling box 32 is connected to the cooling pipe 31 through a conduit 33 . It is not difficult to see from the above design that through the coordinated design of the heat dissipation mechanism 27, the height in the transformer box 1 is absorbed by the heat dissipation belt 28 and...

Embodiment 3

[0032] Such as Figure 1-4 As shown, a temperature sensor 34 is provided on one side of the transformer box 1 and on the side of the installation frame 11, and a temperature sensor 34 is provided on the bottom of the transformer box 1 and on the connecting block one 4 Heat-absorbing mechanism 35, described heat-absorbing mechanism 35 comprises the radiating pipe 36 that is positioned at the bottom end of described connection block 4, and described radiating pipe 36 is provided with some evenly distributed heat-collecting fins 37, and described radiating pipe 36 is U-like Type structure, and the heat dissipation pipe 36 extends to the top of the transformer box 1 with a fan 38, the top of the transformer box 1 is provided with a protective cover sleeved on the fan 38, and the heat dissipation Both the tube 36 and the heat collecting fins 37 are hollow structures, and the interior of the heat dissipation pipe 36 communicates with the interior of the heat collecting fins 37 . It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com