Three-dimensional recycled paper pulp molded product material and preparation method

A technology for recycled pulp and molded products, applied in textiles and papermaking, etc., can solve the problems affecting the stability of the paper-plastic coloring structure, the surface is not smooth and beautiful, easy to rot and deform, etc., to achieve comprehensive performance improvement, smooth surface, not easy to Deformation damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

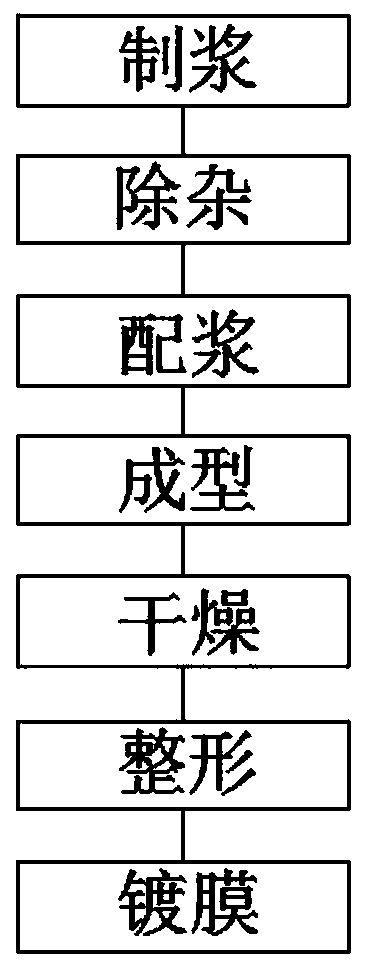

[0027] see figure 1 , the three-dimensional recycled pulp molding product material provided by this implementation, which is made of the following components in parts by weight: recycled plant pulp (calculated as dry fiber) 60-90, acrylic acid emulsion (solid content 50%) 5-10, soap Deinking agent 0.1-0.5, volatile agent 0.01-0.03, rosin gum 2-4, dispersant 0.1-1 part, pigment 0.1-0.3, water-based ceramic coating 0.5-1; water 10-20.

[0028] Specifically, in this embodiment, the weight ratio of each component is: regenerated plant pulp (calculated as dry fiber) 60, acrylic acid emulsion (solid content 50%) 5, soap deinking agent 0.3, volatile agent 0.02, rosin Glue 3, dispersant 0.5, pigment 0.2, water-based ceramic coating 0.5; water 10.

[0029] A method for preparing a three-dimensional recycled pulp molded product, comprising the following steps:

[0030] S1: Pulping, using raw pulp boards, waste paper, cartons, etc. as raw materials, using hydraulic pulping, refining an...

Embodiment 2

[0038] The three-dimensional recycled pulp molding product material and its preparation method provided in this implementation are basically the same as in Example 1, except that:

[0039] Specifically, in this embodiment, the weight ratio of each component is: regenerated plant pulp (calculated as dry fiber) 80, acrylic acid emulsion (solid content 50%) 8, soap deinking agent 0.1, volatile agent 0.01, rosin Glue 2, dispersant 0.1 part, pigment 0.1 part, water-based ceramic coating 0.8 part; water 15 part.

Embodiment 3

[0041] The three-dimensional recycled pulp molding product material and preparation method provided in this implementation are basically the same as those in Examples 1 and 2, except that:

[0042] The three-dimensional recycled pulp molding product material provided by this implementation is made of the following components in parts by weight: recycled plant pulp (calculated as dry fiber) 90, acrylic emulsion (solid content 50%) 10, soap deinking agent 0.5 , volatile agent 0.03, rosin glue 4, dispersant 1 part, pigment 0.3, water-based ceramic coating 1; water 20.

[0043] Among the above-described embodiments, the fatty acid soap deinking agent can be selected as the soap-based deinking agent; the volatile agent is ethanol or ammonia; technical effect.

[0044] The material formula and the preparation method of the present invention match each other, and can remove the ink and tape-like plastics mixed in the pulp, which facilitates the later coloring of the paper and plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com