High-strength high-toughness antioxidant iron-nickel-based high-temperature alloy and preparation method thereof

A nickel-based superalloy, high-strength and high-toughness technology, applied in the field of high-strength, high-toughness, oxidation-resistant iron-nickel-based superalloy and its preparation, can solve problems such as limited increase in material cost, and improve resistance to steam oxidation and flue gas corrosion. , Excellent structural stability and anti-steam oxidation performance, the effect of improving lasting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Alloy composition

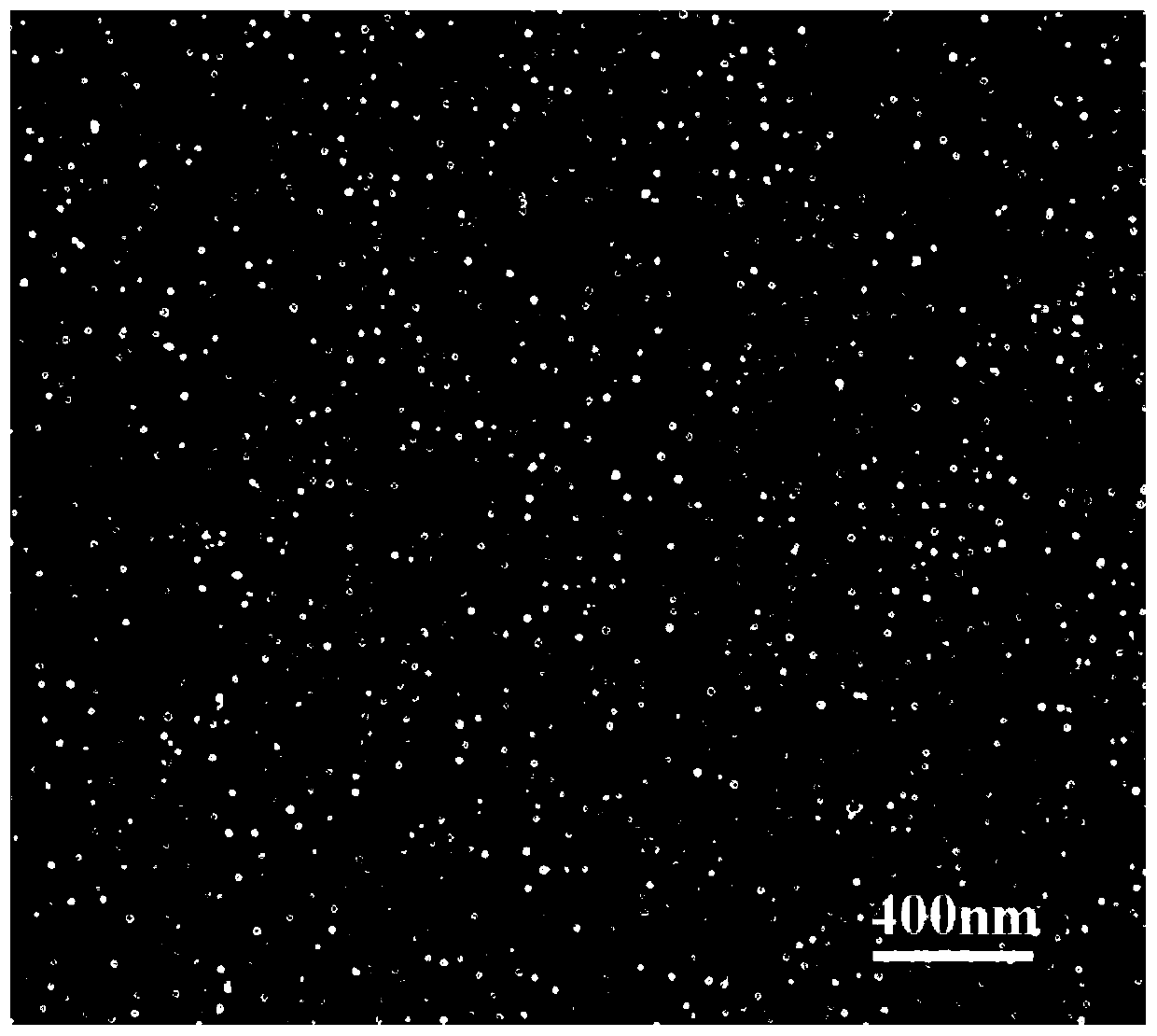

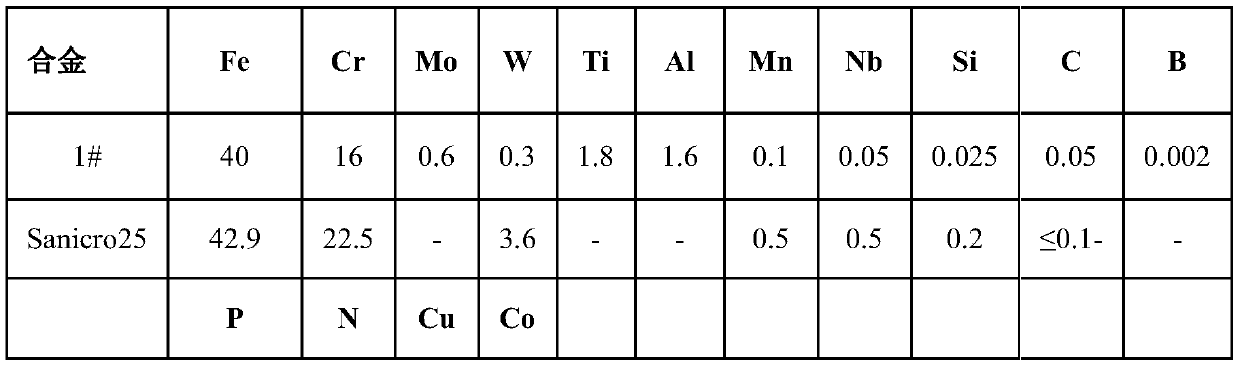

[0029] Table 1 provided the chemical composition of Example 1 of the present invention. Test alloy 1# is the iron-nickel base superalloy of embodiment 1 of the present invention, in order to compare with the highest austenitic heat-resistant steel Sanicro25 alloy (Sweden Sandvik company development) with the present temperature bearing capacity, also listed Sanicro25 in the table ingredients.

[0030] Table 1 Chemical composition (% by weight, balance being Ni) of embodiment 1 of the present invention and comparative example (Sanicro25)

[0031]

[0032]

[0033] 2. Alloy melting and thermal deformation

[0034] By weight percentage, Fe 35-45%, Cr 15-21%, Mo 0.5-1.4%, W 0.1-0.8%, Ti 1.8-2.5%, Al 0.8-2.5%, Mn≤1.0%, Nb≤0.1%, Co≤2%, Si≤0.05%, C0.03-0.10%, B0.001-0.005%, P≤0.01%, the balance is Ni, the weight percentage of Cr+Ni is more than 50%, the weight percentage of W+Mo It is 0.6-1.5%, added to the vacuum induction furnace for melting,...

Embodiment 2-9

[0055] The chemical compositions of the alloys described in Examples 2-9 of the present invention are shown in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com