Method for regulating and controlling grain size of microbial-induced deposited calcite

A grain size, induced deposition technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high cost, complex process, single size of calcium carbonate particles, etc., to achieve stable mineral properties, slow down The effect of the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Inoculate the photosynthetic bacteria into the sterilized medium solution, and each liter of medium contains NH 4 Cl 1.0 g, CH 3 COONa 3.0g, MgCl 2 0.1g, CaCl 2 0.1g, KH 2 PO 4 0.5g, K 2 HPO 4 0.4g, 0.1g of yeast extract, and control the pH to 7, shake culture at 30°C for 24 hours to obtain a bacterial liquid containing photosynthetic bacteria, and the concentration of the bacterial cells contained in the bacterial liquid is 10 6 individual / mL.

[0033] (2) Add calcium source and urea to the above-mentioned microbial bacterial liquid respectively, place in a constant temperature and humidity environment, the temperature is 30°C, and the standing time is 120 hours, wherein the mass ratio of calcium source, urea, and bacterial liquid is 1:0.6 :96.8;

[0034](3) After the precipitation occurs, the sediment is fully washed, filtered, dried, dried to a constant weight, and the grain size analysis is performed to obtain the characteristics of the photosyntheti...

Embodiment 2

[0046] (1) Inoculate the photosynthetic bacteria into the sterilized medium solution, and each liter of medium contains NH 4 Cl 1.5g, CH 3 COONa 4.0g, MgCl 2 0.2g, CaCl 2 0.2g, KH 2 PO 4 0.6g, K 2 HPO 4 0.5g, 0.2g of yeast extract, and control the pH to 8, shake culture at 35°C for 24h to obtain a bacterial liquid containing photosynthetic bacteria, and the concentration of the bacterial cells contained in the bacterial liquid is 10 7 individual / mL.

[0047] (2) Add calcium source and urea to the above-mentioned microbial bacterial liquid respectively, place in a constant temperature and humidity environment, the temperature is 35°C, and the standing time is 150 hours; wherein the mass ratio of calcium source, urea, and bacterial liquid is 2:1.2 :98.4

[0048] (3) After the precipitation occurs, the sediment is fully washed, filtered, dried, dried to a constant weight, and the grain size analysis is carried out to obtain the characteristics of the photosynthetic ba...

Embodiment 3

[0050] (1) Inoculate the photosynthetic bacteria into the sterilized medium solution, and each liter of medium contains NH 4 Cl 1.3g, CH 3 COONa 3.5g, MgCl 2 0.15g, CaCl 2 0.15g, KH 2 PO 4 0.55g, K 2 HPO 4 0.45g, 0.15g of yeast extract, and control the pH to 7.5, shake culture at 32°C for 24 hours to obtain a bacterial liquid containing photosynthetic bacteria, and the concentration of the bacterial cells contained in the bacterial liquid is 10 6 individual / mL.

[0051] (2) Add calcium source and urea to the above-mentioned microbial bacterial liquid respectively, place in a constant temperature and humidity environment, the temperature is 32°C, and the standing time is 130 hours; wherein the mass ratio of calcium source, urea, and bacterial liquid is 1.5:0.8 :97.7

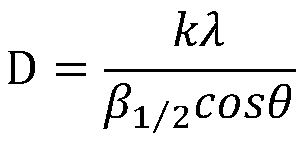

[0052] (3) After the precipitation occurs, the sediment is fully washed, filtered, dried, dried to a constant weight, and the grain size analysis is carried out, measured and calculated according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com