Preparation process of crystalline composition containing D-psicose

A technique of psicose and preparation process, applied in the field of functional sugar preparation, can solve the problems of difficult crystallization, low conversion rate of D-psicose, small crystallization, etc., and achieves reduction of raw material cost, simple preparation method and low calorie Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

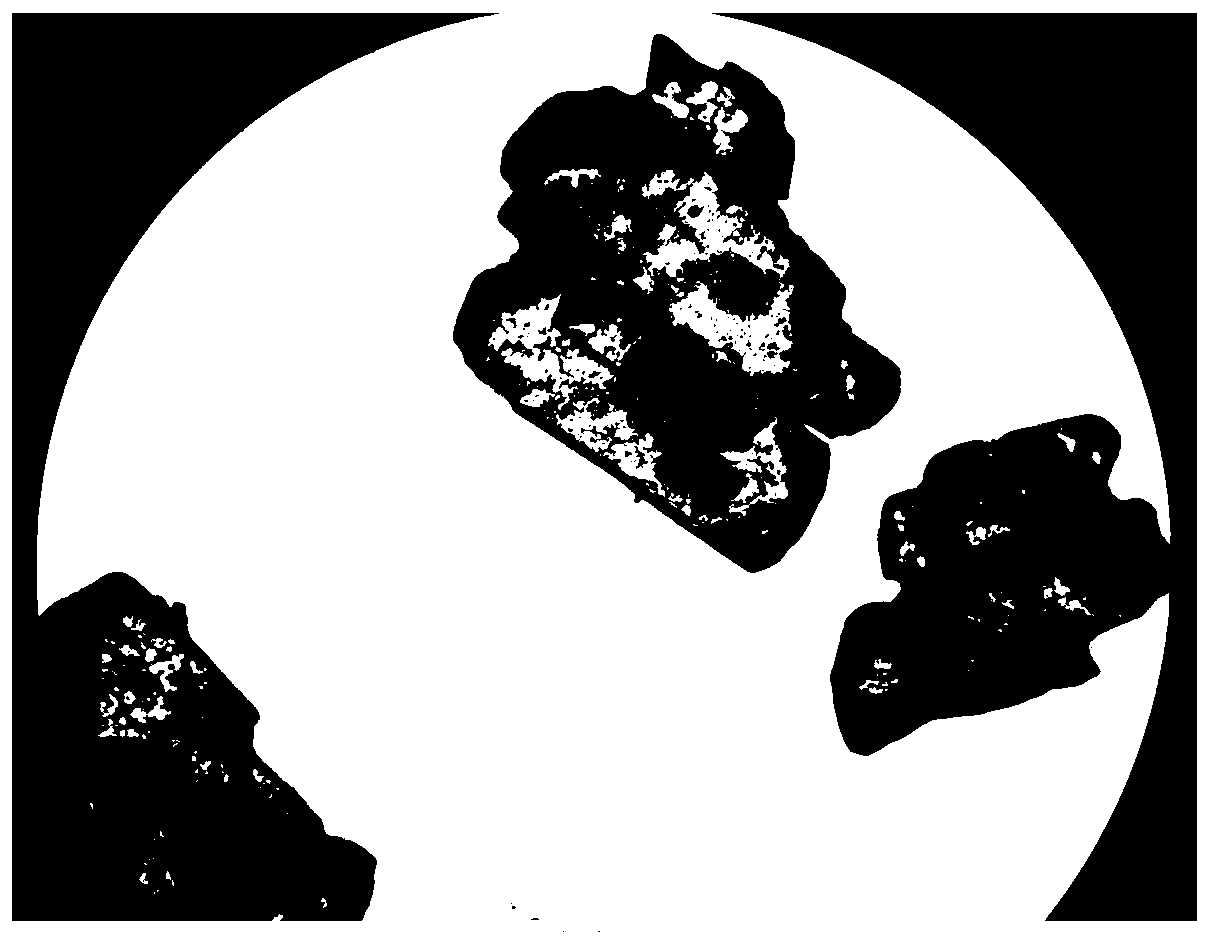

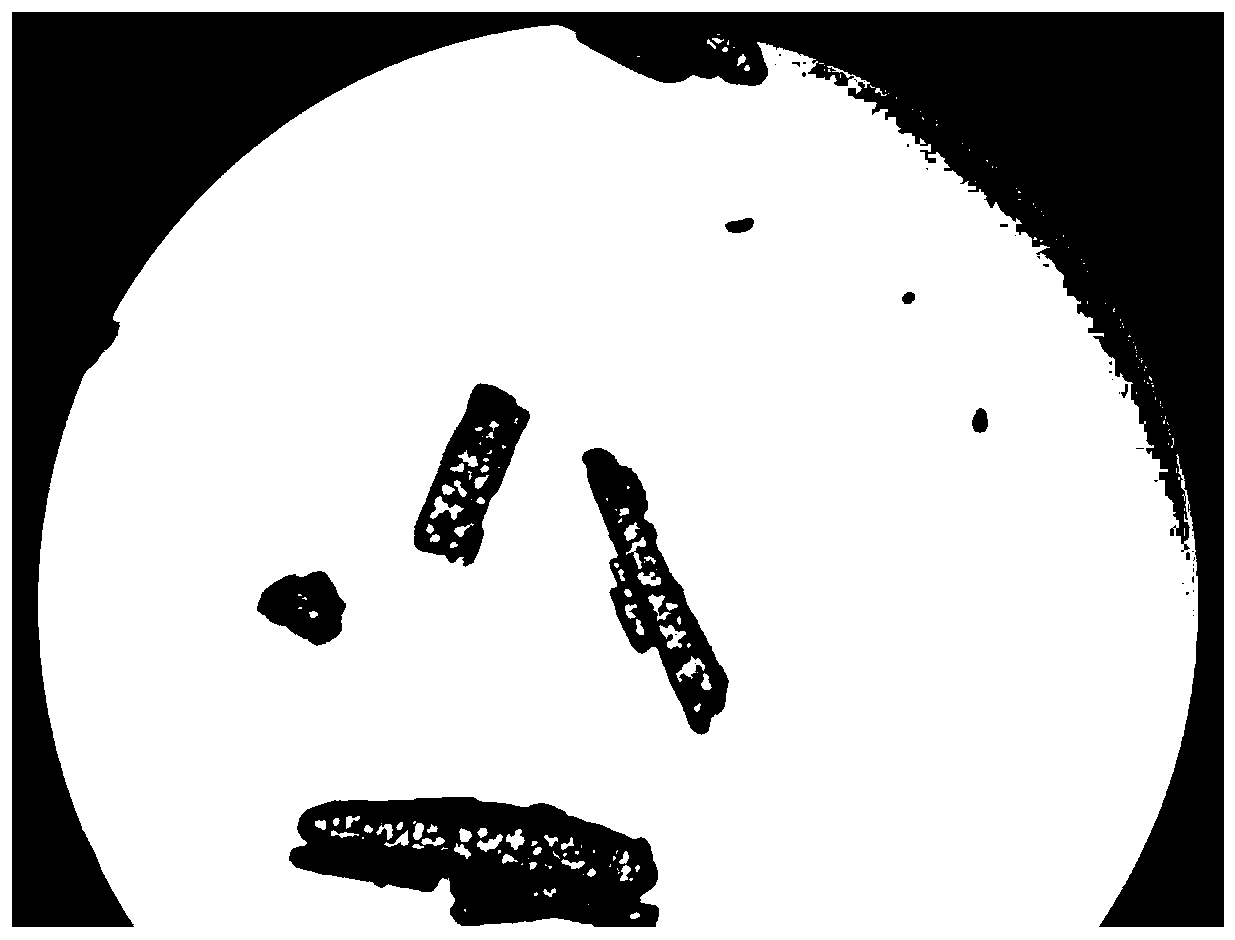

Image

Examples

Embodiment 1

[0030] A preparation process of a crystalline composition containing D-psicose, comprising the following steps:

[0031] (1) Take fructose syrup, dilute it to a sugar concentration of 32.5%, adjust the pH to 6.5, add D-psicose epimerase, and catalyze the reaction at 55°C for 16 hours to obtain D-allulose Compounds of ketose, glucose, and fructose;

[0032] (2) Decolorization: add the compound in step (1) to activated carbon in a ratio of 1% by mass, and stir at 80° C. for 30 minutes;

[0033] (3) Isolation: the decolorized complex in step (2) is passed through a continuous ion exchange system at 40°C at a flow rate of 3 times the resin volume / hour for desalination;

[0034] (4) Concentration: the complex after step (3) is separated and handed over is adopted a four-effect falling film evaporator, the vacuum is 0.08MPa, the temperature of the complex is 80°C, and concentrated to a solid content of 80%, to obtain a complex sugar solution ;

[0035] (5) Crystallization: Contro...

Embodiment 2

[0039] A preparation process of a crystalline composition containing D-psicose, comprising the following steps:

[0040] (1) Take fructose syrup, dilute it to a sugar concentration of 31.0%, adjust the pH to 7.0, add D-psicose epimerase, and catalyze the reaction at 60°C for 20 hours to obtain D-allulose Compounds of ketose, glucose, and fructose;

[0041] (2) Decolorization: add the compound in step (1) to activated carbon in a ratio of 1% by mass, and stir at 80° C. for 30 minutes;

[0042] (3) Isolation: the decolorized complex in step (2) is passed through a continuous ion exchange system at 40°C at a flow rate of 3 times the resin volume / hour for desalination;

[0043] (4) Concentration: the complex after step (3) is separated and handed over is adopted a four-effect falling film evaporator, the vacuum is 0.08MPa, the temperature of the complex is 80°C, and the solid content of the concentrated juice is 85%, to obtain the complex sugar liquid ;

[0044] (5) Crystalliza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com