A kind of aqueous polyurethane-acrylate hybrid copolymer and preparation method thereof

A water-based polyurethane and acrylate technology, applied in the field of water-based polyurethane materials, can solve the problems of difficult control of cross-linking equivalent, insignificant improvement of resistance, unstable emulsion, etc., to achieve stable production process without abnormality, improve physical and mechanical properties, and prepolymerization. Stable and controllable response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

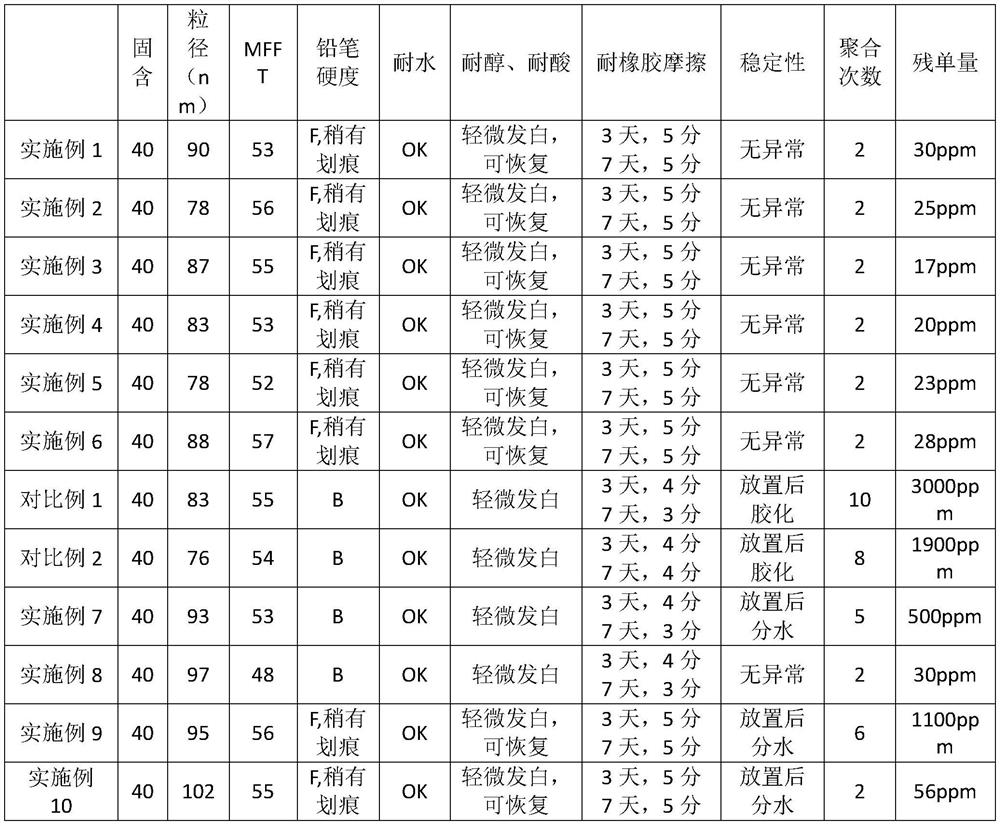

Examples

Embodiment 1

[0084] Add 80g WANNATE HMDI, 40g hydrogenated castor oil (iodine value 10-15), 40g PCL220N, and 0.05g organic bismuth catalyst, 24g acetone into a four-neck flask equipped with a thermometer, reflux condenser, and stirrer, heat up to 85°C and keep it warm for reaction , when the NCO value is constant at 10.36%, lower the temperature to 55°C, add 8g of dimethylolpropionic acid, 10g of 1,4-butanediol and 23g of acetone, and react at 75-80°C for 3-4 hours until the NCO value is constant to 2.72wt%, lower the temperature to 50°C, add 76g of acetone, 153.73g of methyl methacrylate, and 6.04g of triethylamine, and stir for 10 minutes until uniform. After cooling down to room temperature, add 450 g of water at a shear rate of 1300 rpm, emulsify and disperse for 10 min, add 14.17 g of tris(4-aminophenyl)amine to the dispersed emulsion, dilute it with 4 times water, and stir for 5 min. Add 1.92g of 4,4-diaminodicyclohexylmethane, dilute it with 4 times of water and add it, and stir for...

Embodiment 2

[0087] Add 80g WANNATEHMDI, 20g hydrogenated castor oil (iodine value 10-15), 60gPCL220N, and 0.18g organic bismuth catalyst, 24g acetone to a four-neck flask equipped with a thermometer, reflux condenser, and stirrer, heat up to 85°C and keep warm for reaction , when the NCO value is constant at 11.23wt%, lower the temperature to 55°C, add 10g of dimethylol propionic acid, 12g of 1,4-butanediol and 20g of acetone, and react at 75-80°C for 3-4 hours to reach the NCO value Constant at 2.16wt%, lower the temperature to 40°C, add 77g of acetone, 154.65g of methyl methacrylate, and 7.55g of triethylamine, and stir for 10 minutes until uniform. After cooling down to room temperature, add 451g of water at a shear rate of 1300rpm, emulsify and disperse for 10min, add 11.31g of tris(4-aminophenyl)amine to the dispersed emulsion, dilute with 4 times of water, add, and stir for 5min. Add 3.87g of 4,4-diaminodicyclohexylmethane, dilute it with 4 times of water and add it, and stir for 8 ...

Embodiment 3

[0090] Add 80g WANNATE HMDI, 60g hydrogenated castor oil (iodine value 10-15), 20g PNA2000, and 0.18g organic bismuth catalyst, 24g acetone to the four-neck flask equipped with thermometer, reflux condenser and stirrer, heat up to 85°C and keep warm for reaction , when the NCO value is constant at 9.49wt%, cool down to 55°C, add 8g of dimethylolpropionic acid, 7g of 1,4-butanediol and 26.3g of acetone, and react at 75-80°C for 3-4h to NCO The value is constant at 3.07wt%. Cool down to 50°C, add 79g of acetone, 152.77g of methyl methacrylate, and 6.04g of triethylamine, and stir for 10 minutes until uniform. After cooling down to room temperature, add 451g of water at a shear rate of 1300rpm, emulsify and disperse for 10min, add 15.96g of tris(4-aminophenyl)amine to the dispersed emulsion, dilute it with 4 times of water, add it, and stir for 5min. Add 7.64g of 4,4-diaminodicyclohexylmethane, dilute it with 4 times of water and add it, and stir for 8min.

[0091] Add the emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com