A kind of low-expansion high-temperature resistant environment-friendly medium and low temperature transparent glass glaze preparation method

A technology of transparent glass and high temperature resistance, which is applied in the preparation of environmentally friendly medium and low temperature transparent glass glazes, and the preparation of environmentally friendly medium and low temperature transparent glass glazes with low expansion and high temperature resistance. Environmentally friendly and quality-improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

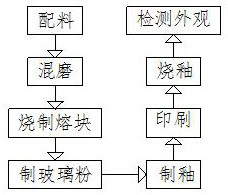

Image

Examples

Embodiment 1

[0024] A method for preparing low-expansion, high-temperature-resistant, environment-friendly, medium- and low-temperature transparent glass glaze, the preparation method comprising the following steps:

[0025] (1) Ingredients, SiO2 55wt% to 70wt%, Al2O3 10wt% to 15wt%, B2O3 13wt% to 15wt%, ZrO25wt% to 10wt%, Li2O 7wt% to 10wt%, MgO 5wt% to 10wt%, ZnO 5wt% to 10wt%, flux 2wt% to 3%, the particle size of each raw material is controlled at less than 10μm;

[0026] (2) Mixed milling, put the materials in step (1) into a ball mill, dry ball milling for 6 hours;

[0027] (3) Burn the frit, put the ball-milled material in step (2) into the frit furnace for melting, the melting temperature is 1330°C to 1350°C, keep warm for 20min, and water quench;

[0028] (4) Making glass powder, milling the frit fired in step (3) through a wet ball mill, then controlling the particle size of the powder to be less than 3 μm, and drying;

[0029] (5) Glazing, mixing 60wt% of the glass powder in s...

Embodiment 2

[0041] A method for preparing low-expansion, high-temperature-resistant, environment-friendly, medium- and low-temperature transparent glass glaze, the preparation method comprising the following steps:

[0042] (1) Ingredients, SiO2 45wt% to 55wt%, Al2O3 5wt% to 10wt%, B2O3 10wt% to 13wt%, ZrO20wt% to 5wt%, Li2O 3wt% to 7wt%, MgO 0wt% to 5wt%, ZnO 0wt% to 5wt%, flux 0wt% to 2%, the particle size of each raw material is controlled at less than 10μm;

[0043] (2) Mixed milling, put the materials in step (1) into a ball mill, dry ball milling for 6 hours;

[0044] (3) Burn the frit, put the ball-milled material in step (2) into the frit furnace for melting, the melting temperature is 1300°C to 1330°C, keep warm for 20min, and water quench;

[0045] (4) Making glass powder, milling the frit fired in step (3) through a wet ball mill, then controlling the particle size of the powder to be less than 3 μm, and drying;

[0046] (5) Glazing, mixing 60wt% of the glass powder in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com