X zeolite molecular sieve and preparation method thereof

A zeolite molecular sieve and alkaline technology, which is applied in the field of molecular sieves, can solve the problems of high energy consumption and complicated process of high-temperature roasting, and achieve the effects of good crystallinity, simple process and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention provides a kind of preparation method of X zeolite molecular sieve, comprises the following steps:

[0027] The lithium slag and the sodium-containing alkaline compound are first mixed and activated to obtain an activated material; the activation temperature is 180-220°C;

[0028] Mixing the activated material and water for the second time to obtain a sol;

[0029] The sol is hydrothermally crystallized to obtain X zeolite molecular sieve.

[0030] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0031] In the invention, the lithium slag and the sodium-containing alkaline compound are first mixed and activated to obtain an activated material; the activation temperature is 180-220°C.

[0032] In the present invention, the composition of the lithium slag is preferably based on spodumene and quartz; the lithium slag preferably includes the ...

Embodiment 1

[0060] Mix and grind 0.715g of lithium slag and 1.12g of sodium hydroxide until no obvious sodium hydroxide particles are observed, add it to a closed activation reaction vessel, activate it at 140°C for 1 hour, then let it stand and cool to room temperature to obtain the activated material.

[0061] Transfer the activated material to a crystallization reaction kettle, add 7.5 mL of distilled water, and stir evenly for 4 hours under airtight and room temperature conditions to obtain a sol, and the molar ratio of active ingredients in the obtained sol is SiO 2 :Al 2 o 3 : Na 2 O: H 2 O=5.67:1:13:300.

[0062] The sol was statically crystallized at 100°C for 6 hours, the resulting system was filtered, the obtained solid was washed with water until its pH value was 9, and then dried at 120°C for 6 hours to obtain X zeolite molecular sieve (abbreviated as A1).

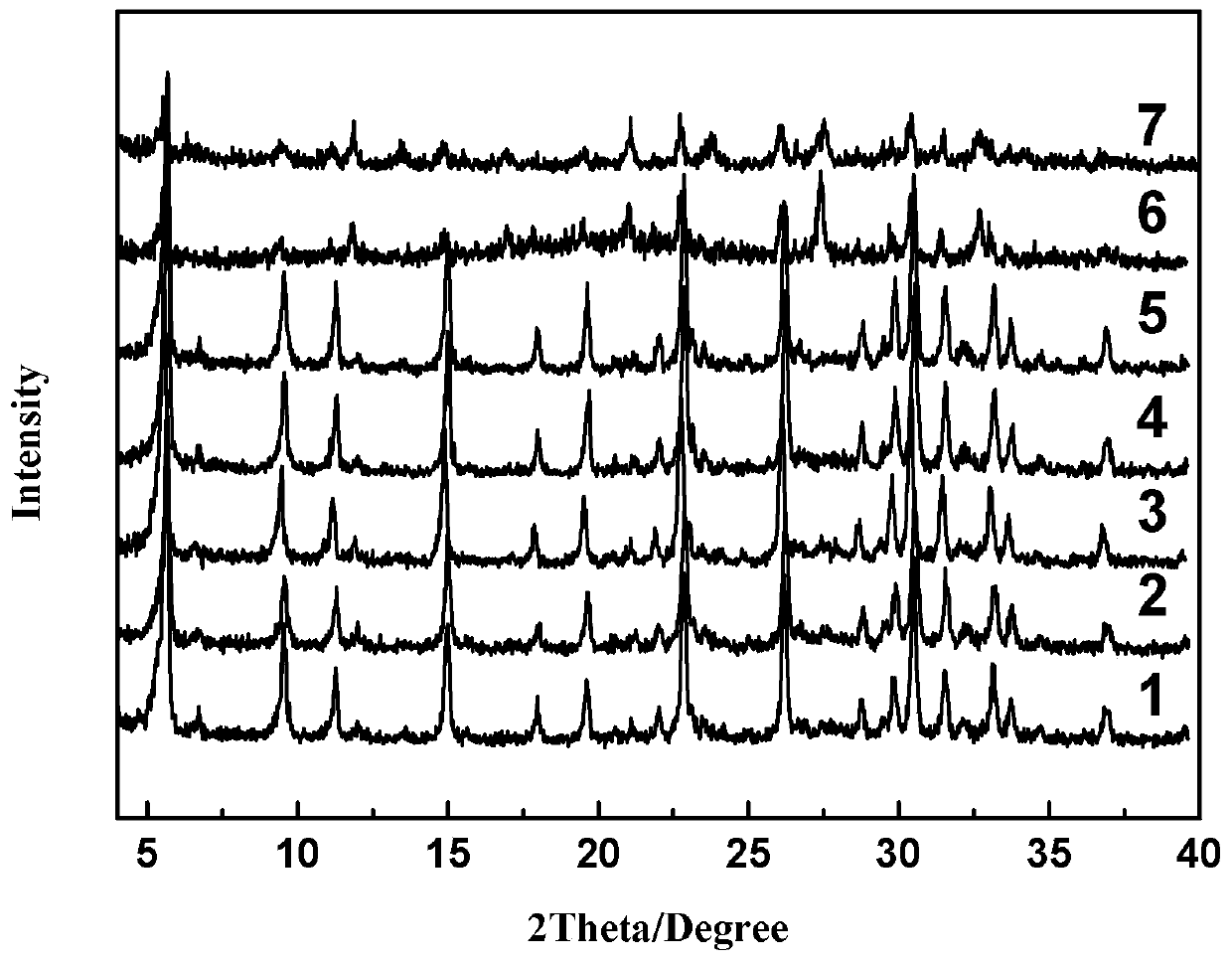

[0063] The XRD pattern of A1 is as follows figure 1 As shown in curve 1, by figure 1 It can be seen that the curve...

Embodiment 2

[0067] 0.715g of lithium slag and 1.45g of sodium hydroxide were mixed and ground until no obvious sodium carbonate particles were observed, then added to a closed activation reaction vessel, activated at 180°C for 4 hours, then allowed to stand and cooled to room temperature to obtain an activated material.

[0068] The activated material was transferred to a crystallization reaction kettle, 20mL of distilled water was added, stirred evenly for 4h under airtight conditions at room temperature, and 0.38g of silica sol (SiO 2 Content 30wt%), stir evenly, obtain sol, the active ingredient molar ratio in the gained sol is SiO 2 :Al 2 o 3 : Na 2 O: H 2 O=7:1:13:800.

[0069] The sol was dynamically crystallized at 120°C for 12 hours, the resulting system was filtered, the obtained solid was washed with water until its pH value was 9, and then dried at 120°C for 6 hours to obtain X zeolite molecular sieve (abbreviated as A2).

[0070] The XRD pattern of A2 is as follows figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com