Method for forming grid structure composite material component

A composite material component and grid structure technology, applied in the aviation field, can solve the problems of difficult molding, complex structure, and failure to produce successfully, and achieve the effects of weight reduction, high dimensional accuracy, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

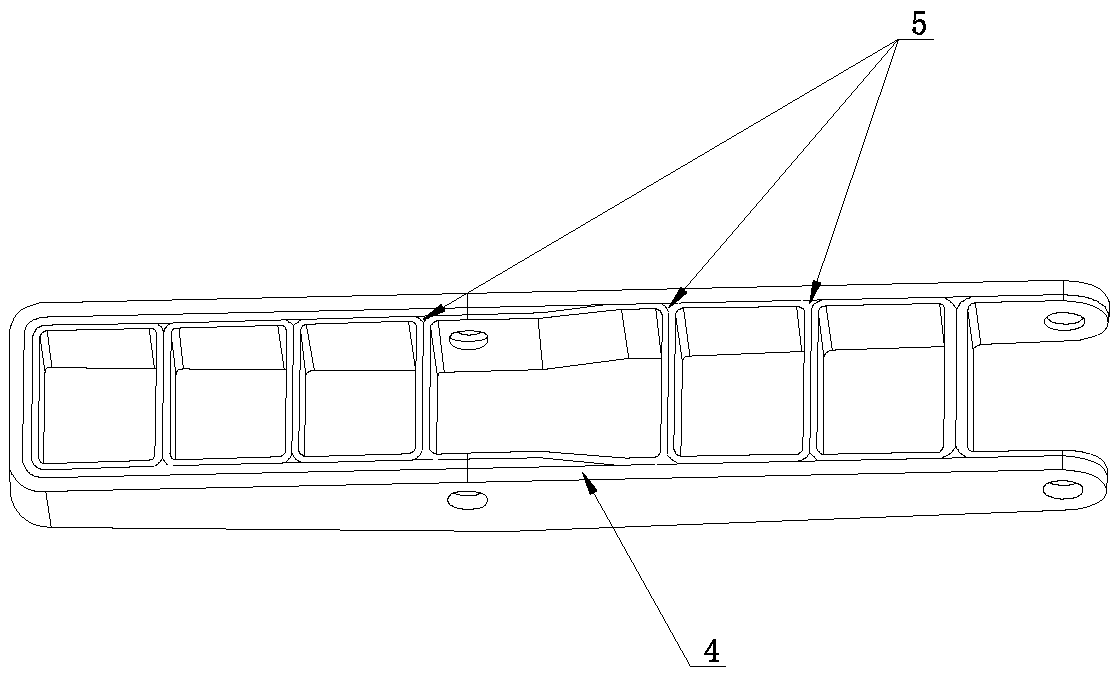

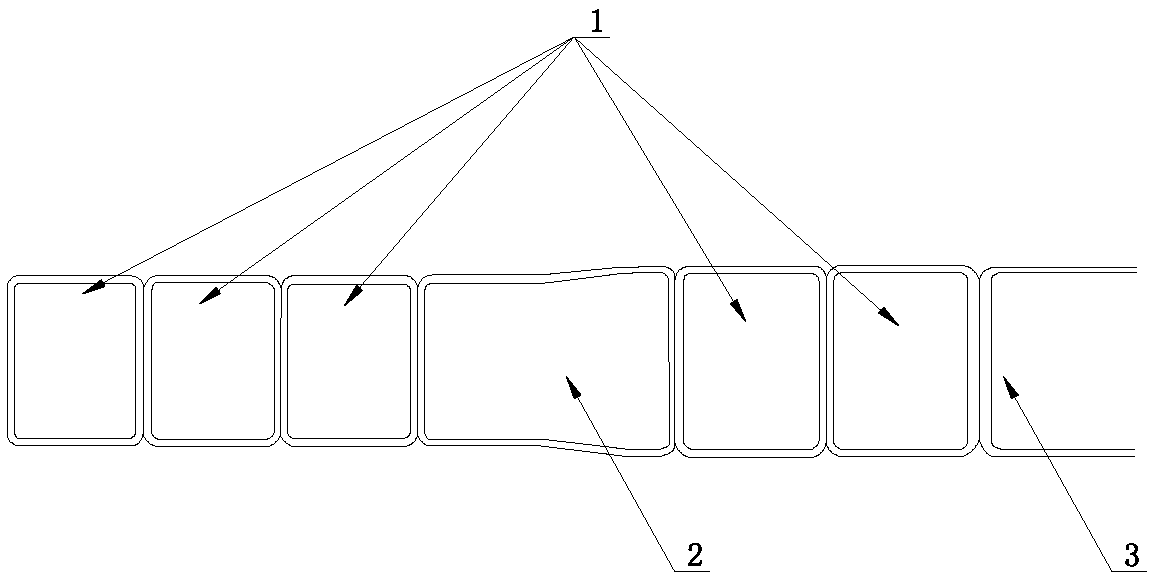

[0029] As shown in the figure, a method for forming a grid structure composite member includes the following steps:

[0030] Step 1: The grid structure is formed in partitions, using the autoclave process to separately form multiple frames and side wall panels 4, the multiple frames include 6 closed back frames and 1 C-shaped frame, and 6 closed back frames It includes five first typical frames 1 and one second typical frame 2, the C-shaped frame is the third typical frame 3, and the side wall panels 4 are U-shaped side wall panels. Grid structure partition molding specifically includes: using vacuum bag autoclave preforming process, using unidirectional prepreg to prefabricate the first typical frame 1 according to the designed layup sequence, the first typical frame 1 is a closed structure, using butt layup Form, the joints need to be staggered, vacuum once every 5 layers, compact and discharge air bubbles, make bags and put them into autoclave for final curing;

[0031] Ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com