Rebar bending machine discharged material automatic transferring and classifying system and method

A steel bar bending hoop and classification system technology, applied in the direction of conveyor objects, transportation and packaging, and other household appliances, can solve the problems of personal safety hazards of operators, cannot be classified, and can only be transported, so as to reduce the cost of human resources, Effects of improving production level and enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

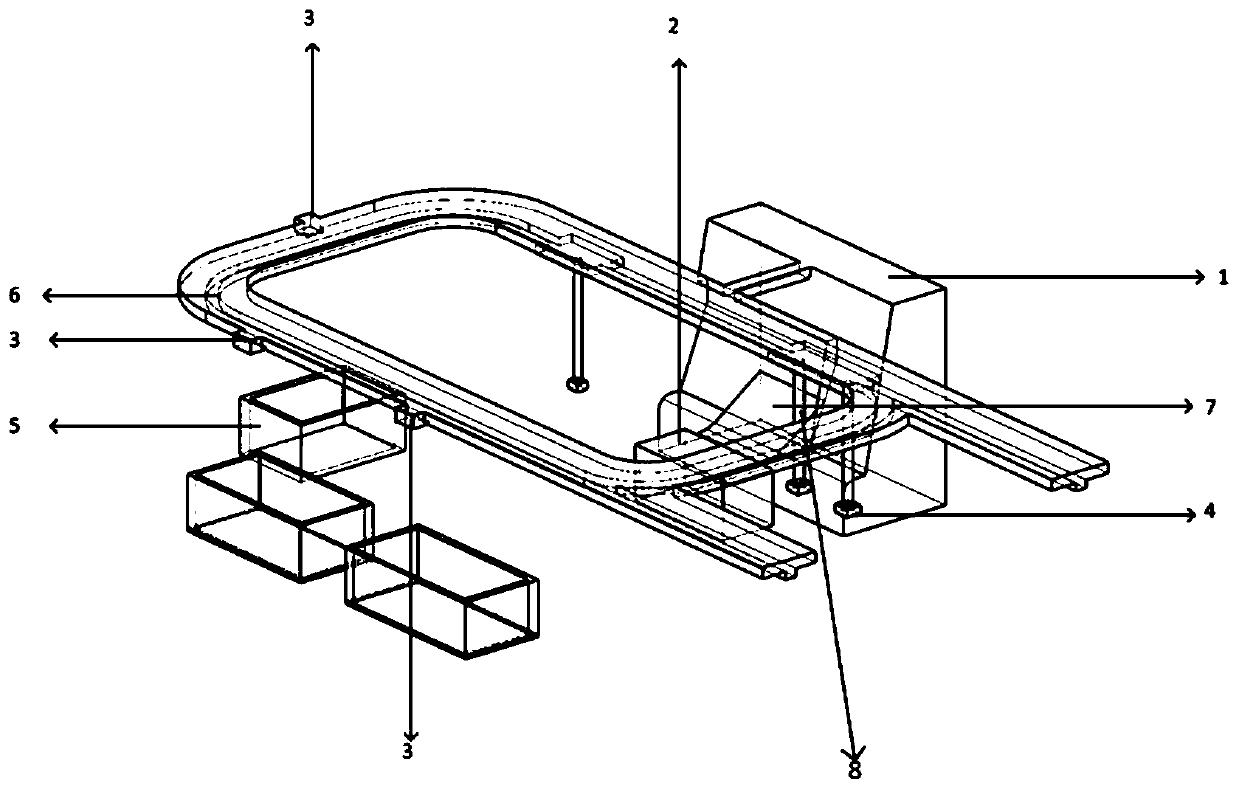

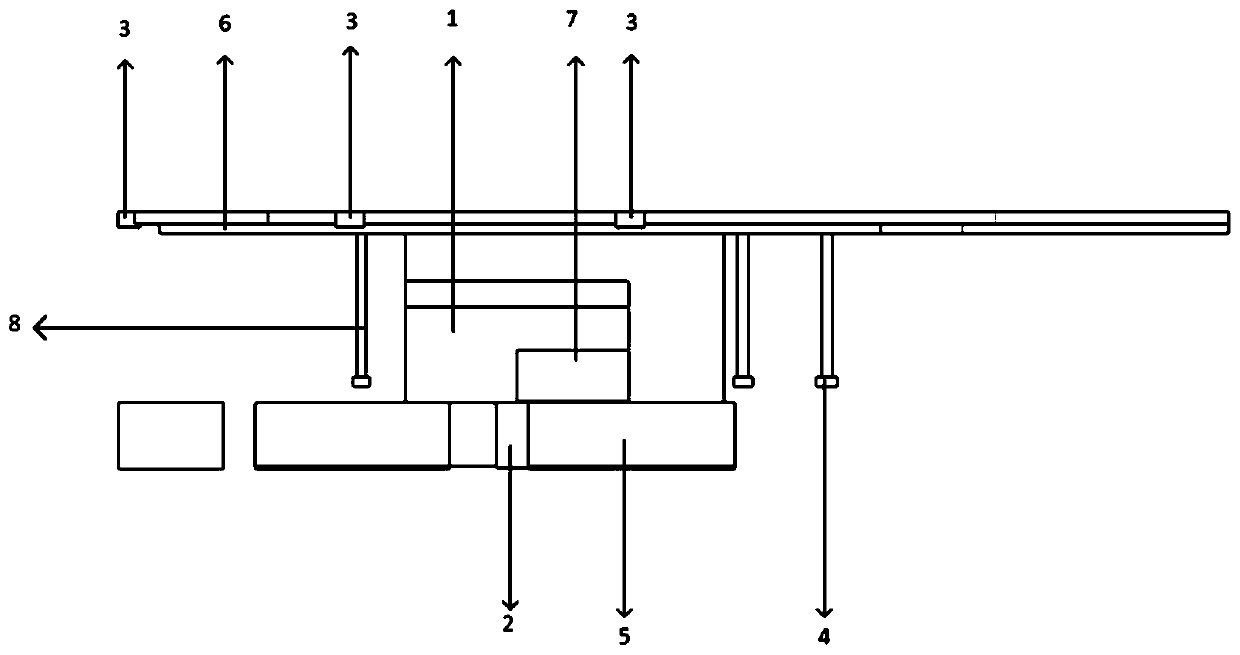

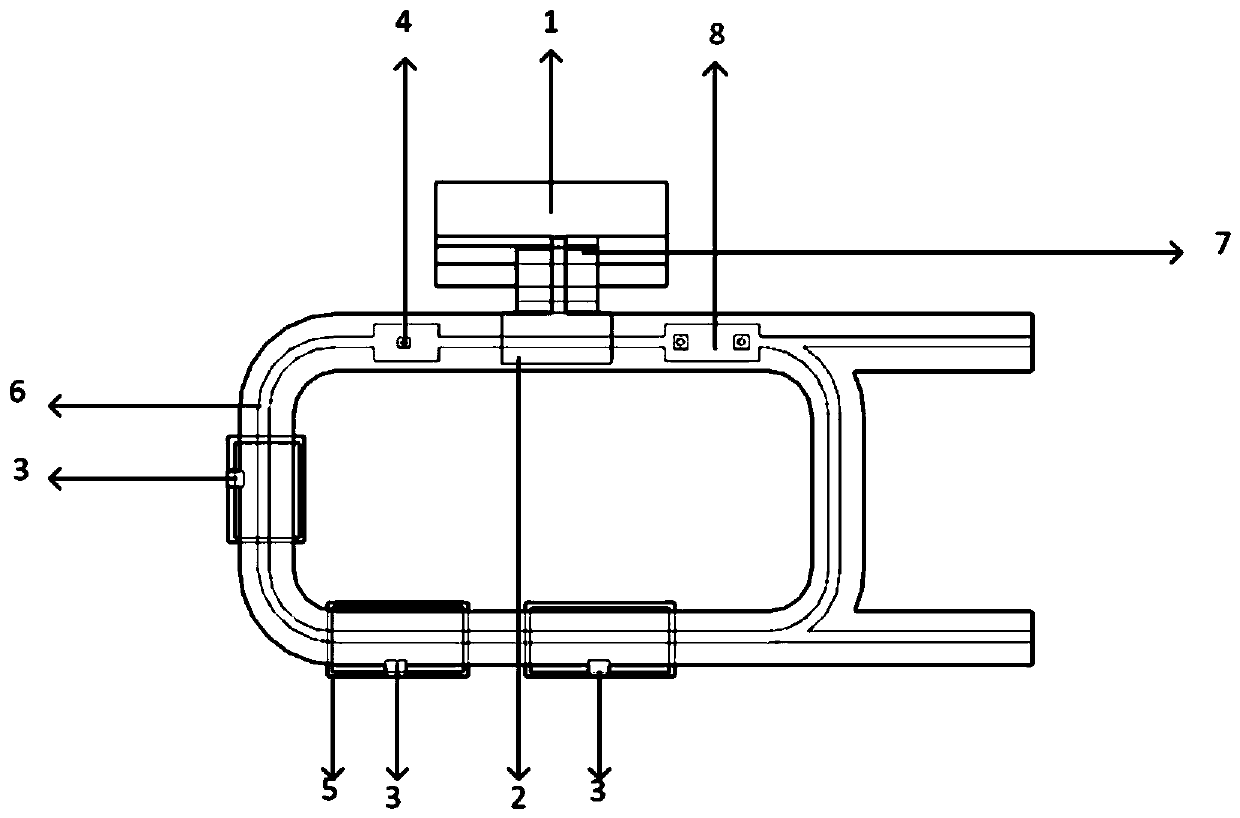

[0028] please see Figure 1-4 , a kind of steel bar hoop bending machine discharge automatic transfer classification system provided by the present invention, comprises hoop bending machine 1, material receiving table 2, sensor 3, electromagnet 4, shipping tank 5, track 6, discharge port 7, clamp 8;

[0029] The electromagnet 4 is installed on the top of the material receiving platform 2, below the track 6, fixed by the clamp 8, and moves through the track 6;

[0030] A plurality of sensors 3 are arranged on the track 6 and directly above the shipping tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com